Non-contact tension buffering coiled material feeding device

A feeding device, non-contact technology, applied in the direction of winding strip material, thin material handling, transportation and packaging, etc., can solve the problems of increasing material deformation, reducing material drawing accuracy, affecting product quality, etc., and increasing the drawing accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

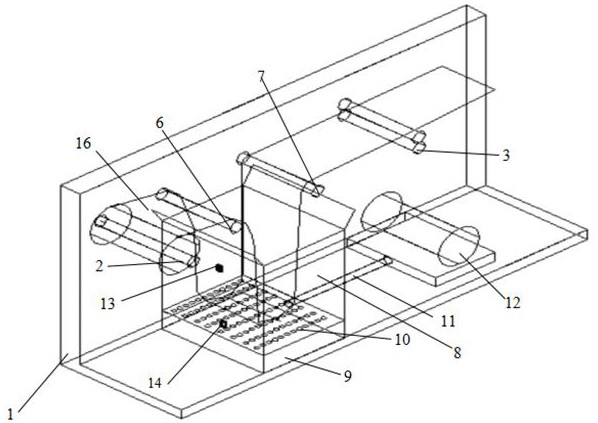

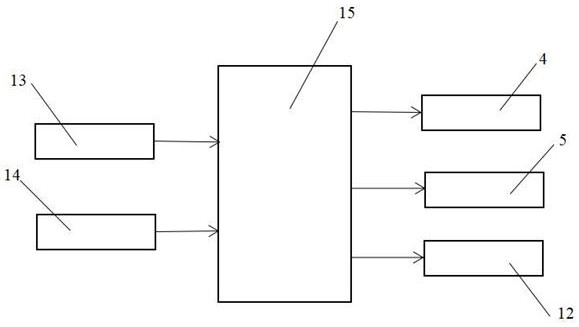

[0016] The non-contact buffer tension coil feeding device of the present invention is as follows: figure 1 As shown, as in the prior art, there is a frame 1, on which a feeding shaft 2 and a pulling roller 3 are fixed, and the driving roller of the pulling roller 3 is driven by a pulling motor (4), which is different from the prior art. The feeding shaft 2 is driven by a feeding motor 5, and a front supporting roller 6 and a rear supporting roller 7 are arranged between the feeding shaft 2 and the pulling roller 3 in turn. A buffer box 8 with an upper opening, a vacuum platform 9 is fixed at the bottom of the buffer box 8, a plurality of through holes 10 are evenly distributed on the upper surface of the vacuum platform 9, and the vacuum platform 9 is connected to the vacuum pump 12 through a pipeline 11. In the buffer box 8, the upper and lower ends of the side wall near the front support roller 6 are correspondingly provided with an upper feeding sensor 13 and a lower feedin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com