Prestress tension control system and control method

A control system and prestressing technology, applied in the direction of control/regulation system, mechanical pressure/force control, non-electric variable control, etc., can solve the problem of poor synchronization, uncertainty of final tension results of components, and prestress tension that does not conform to requirements and other issues to achieve the effect of avoiding tension changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

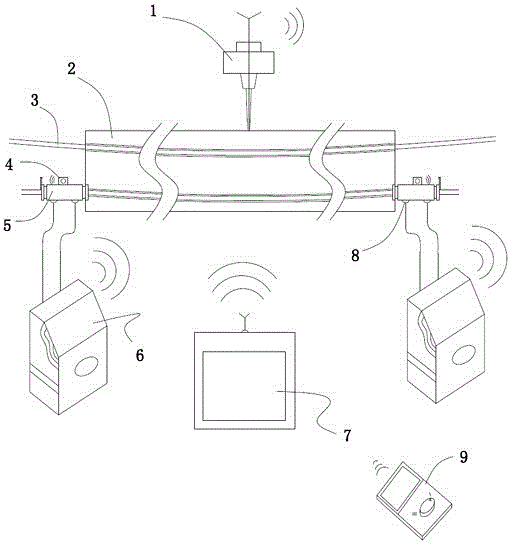

[0028] Embodiment: a kind of prestress tension control system (see attached figure 1 ), including two symmetrical independent tensioning parts and two front-end controllers 6 connected with the tensioning parts and controlling the tensioning parts, a system host 7 for wireless data exchange with the front-end controller, and a manual operator 9 and set on Camber measurement displacement sensor 1 on the upper surface of component 2 .

[0029] The tensioning part is a jack 5, and a displacement sensor 4 is installed outside the jack. The jack is connected with a numerically controlled high-pressure flow pump and a numerically controlled high-pressure unloading valve, which are connected with the front-end controller. The jack is connected with a Oil pressure sensor 8. The CNC high-pressure flow pump includes a flow pump and a servo motor; the jack is also connected to a CNC high-pressure unloading valve, and the CNC high-pressure unloading valve includes an unloading valve and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com