Automobile steering gear pressing block and steering gear

A technology of automobile steering gear and steering gear, which is applied in the direction of mechanical steering gear, etc. It can solve the problems of limited buffer capacity, extra cost and man-hours, and gaps that cannot be adjusted, so as to save costs, avoid failure risks, and save assembly man-hours.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

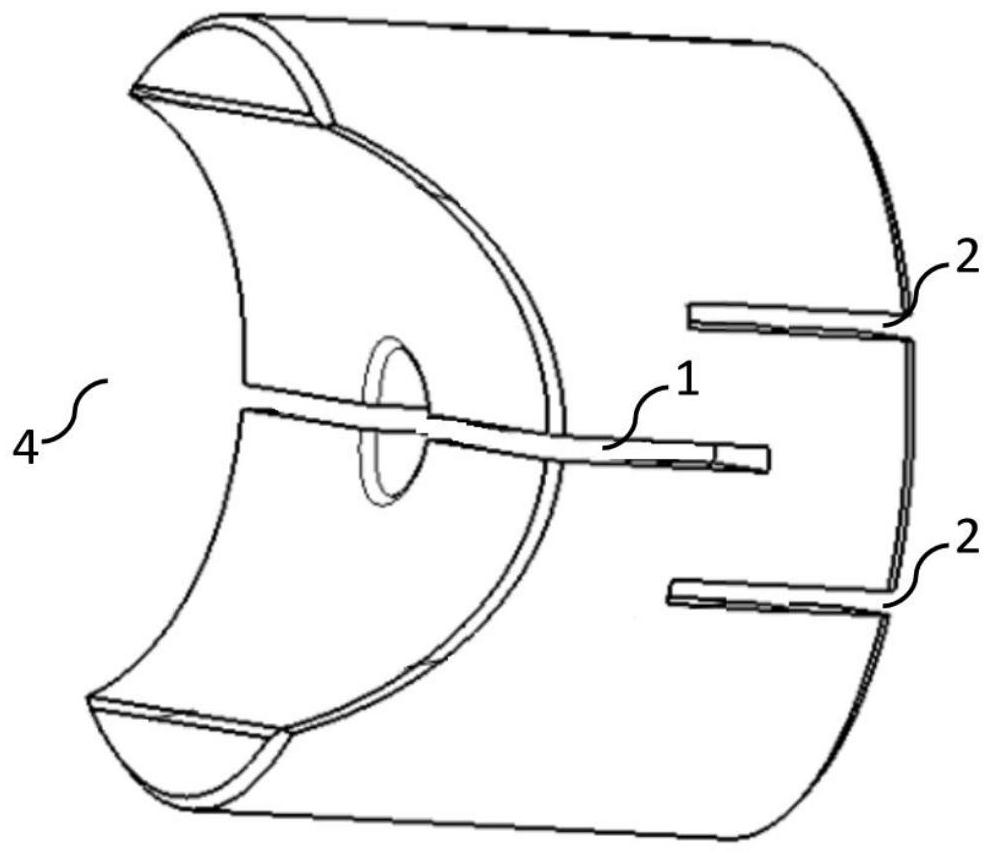

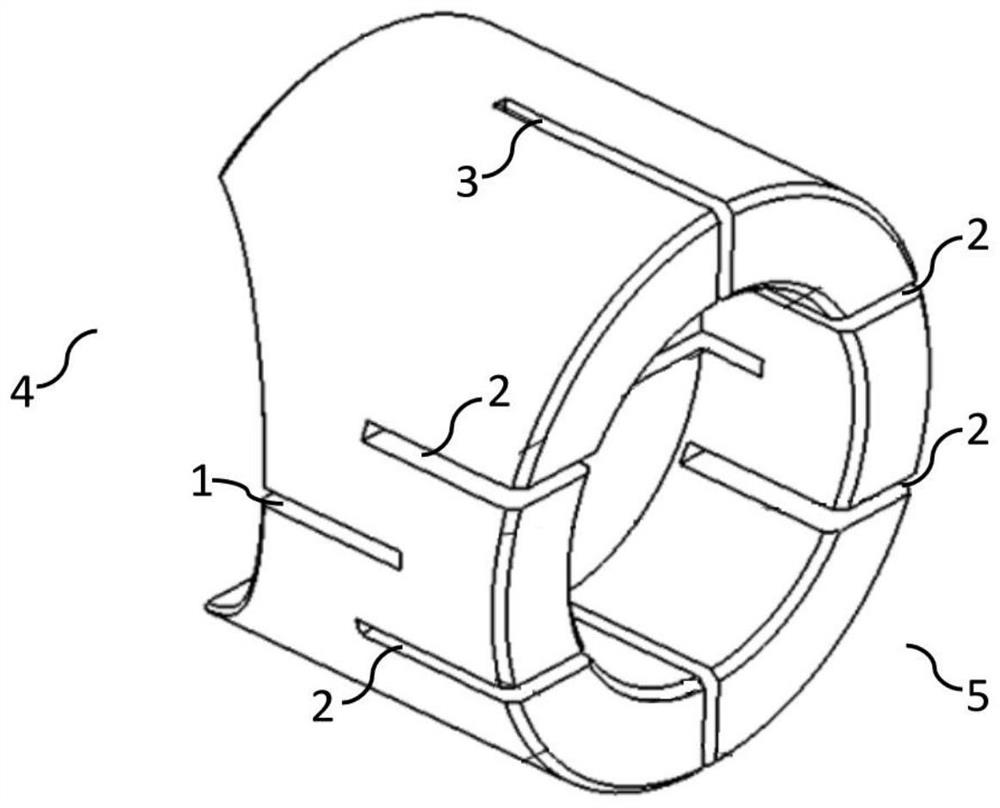

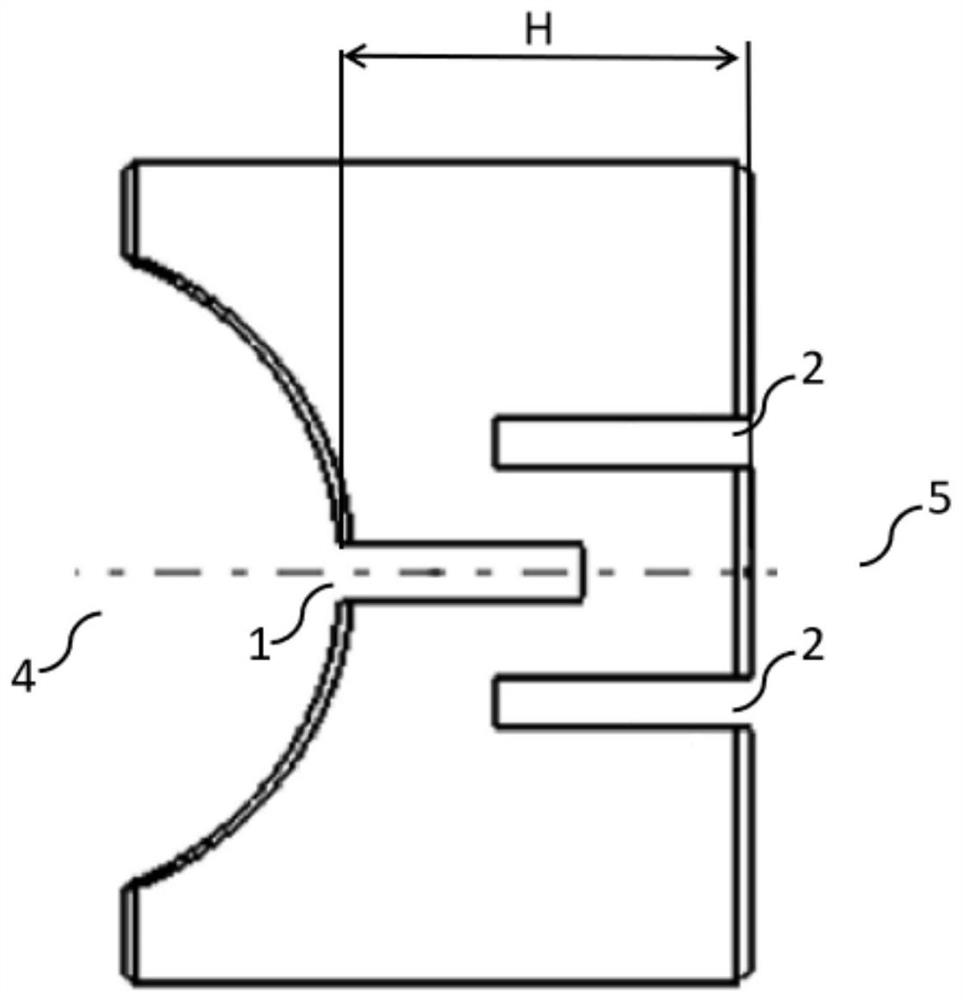

[0028] figure 1 It is a schematic diagram of a three-dimensional structure according to an embodiment of the present invention. figure 2 It is a schematic three-dimensional structure diagram from another perspective according to an embodiment of the present invention. In one embodiment, as figure 1 and figure 2 As shown, the pressure block of the automobile steering gear includes a pressure block body, and the pressure block body is cylindrical and has a first end 4 and a second end 5 arranged oppositely, and the first end 4 is an inner part matched with the steering gear rack. Concave arc surface, in addition, at least one first groove 1 is provided on the pressing block body, which traverses the inner concave arc surface and extends in the depth direction toward the second end 5; and the second end 5 is provided with multiple The second grooves 2 are spaced apart, and the second grooves 2 are equally spaced on both sides of the first groove 1 , and the depth direction o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com