Auxiliary device for balance shaft

An auxiliary device and balance shaft technology, which is applied in the direction of balance weight, spring/shock absorber, vibration suppression adjustment, etc., can solve problems such as noise and instantaneous force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

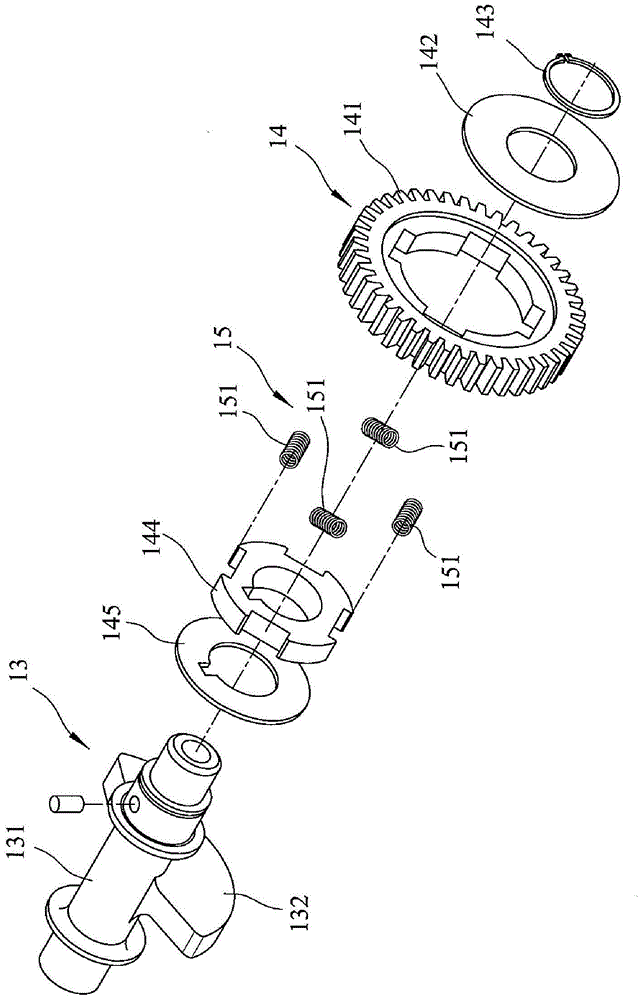

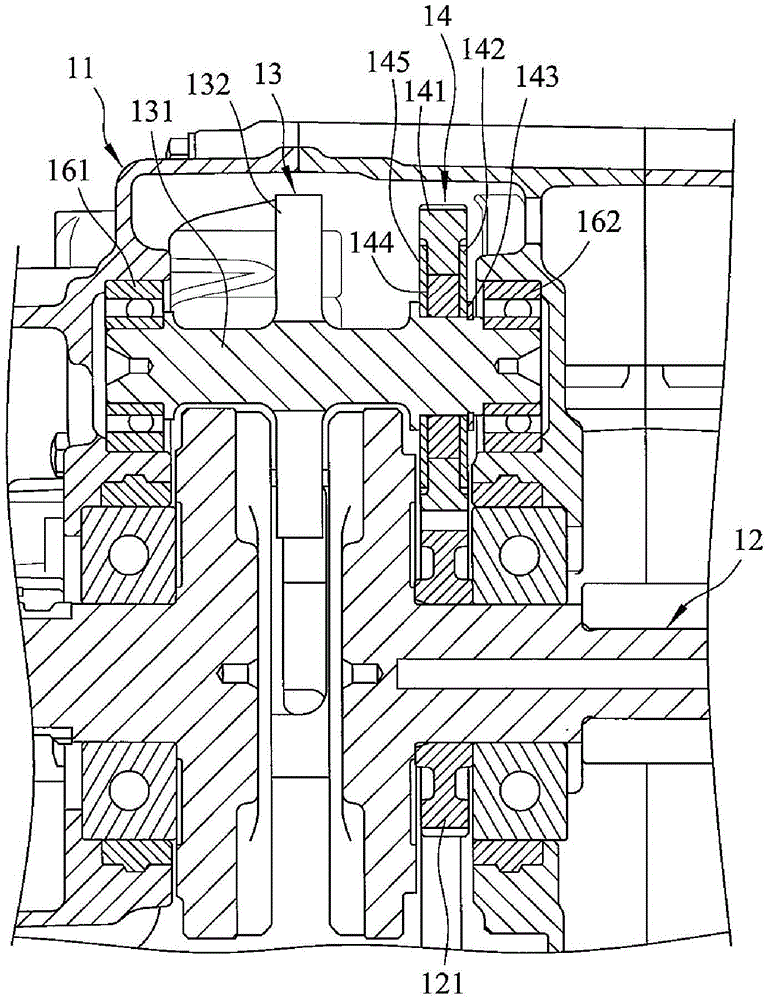

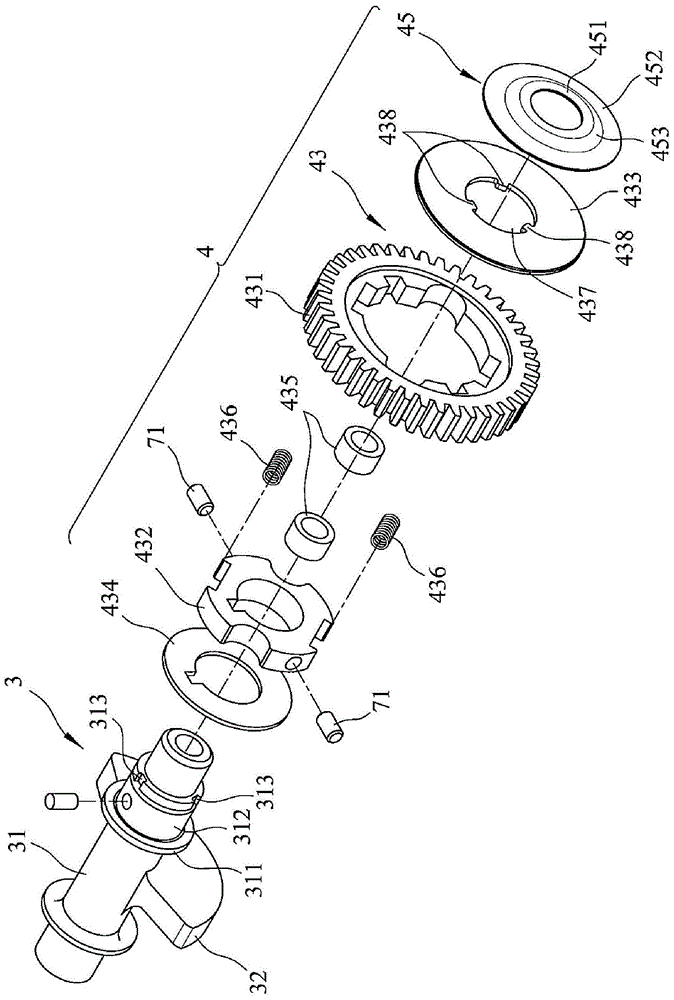

[0019] refer to image 3 , 4 , is the first preferred embodiment of the auxiliary device 4 of the balance shaft 3 of the present invention, the balance shaft 3 is pivotally arranged in a crankcase 5, and a positioning unit 6 is provided in the crankcase 5, and the positioning unit 6 includes a A first rotating bearing 61 and a second rotating bearing 62 . The balance shaft 3 includes a shaft 31 pivotally disposed in a crankcase 5 , and a counterweight 32 located on the shaft 31 . The first rotating bearing 61 includes a fixed outer ring 611 , a movable inner ring 612 disposed inside the fixed outer ring 611 , and a ball 613 disposed between the fixed outer ring 611 and the movable inner ring 612 . Similarly, the second rotating bearing 62 also includes a fixed outer ring 621, a movable inner ring 622 disposed inside the fixed outer ring 621, and a movable inner ring 622 disposed between the fixed outer ring 621 and the movable inner ring 622. Ball 623. Two ends of the shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com