Outer coating layer feeding mechanism of FRPP three-layer wall reinforced pipe production equipment

A technology of production equipment and outer cladding, which is applied in the field of the outer cladding material feeding mechanism, can solve the problems of uneven coating of the outer cladding layer, and achieve the effects of improving uniformity and stability, stable feeding and stable positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

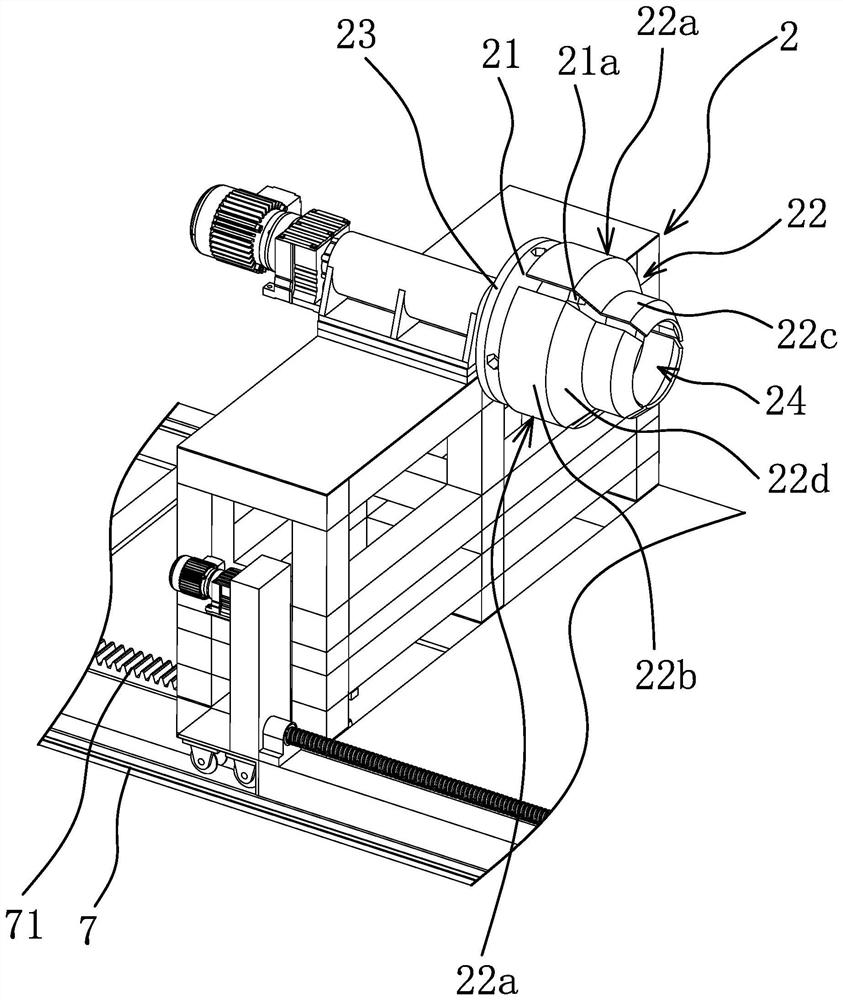

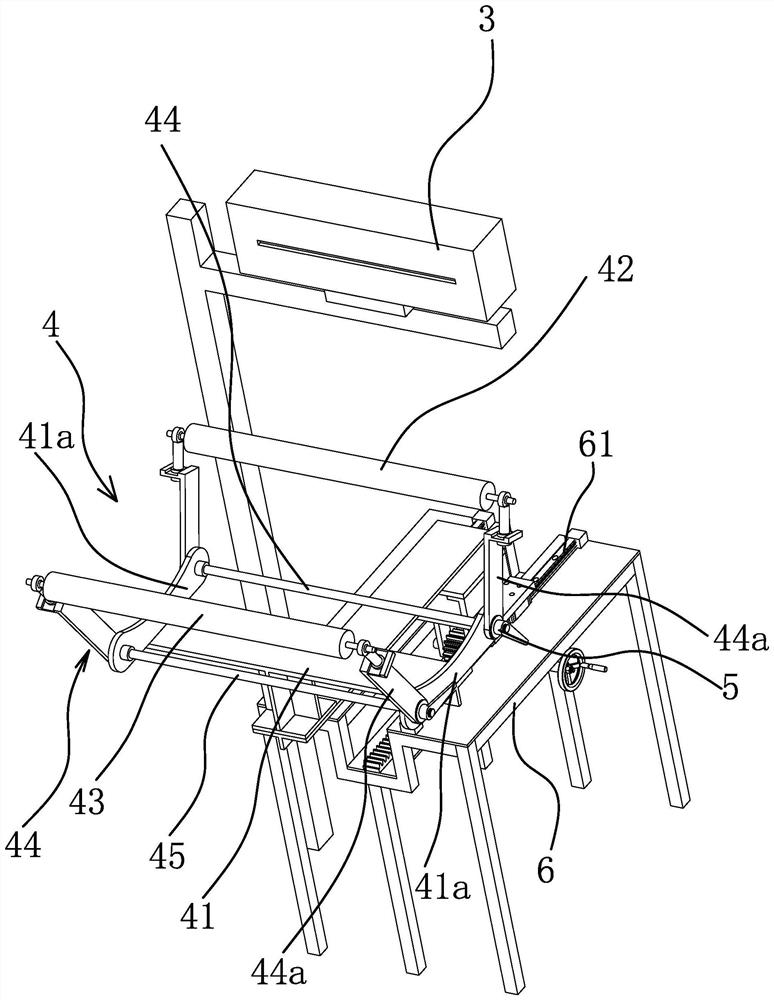

[0039] like figure 1 As shown, the outer cladding feeding mechanism of the FRPP three-layer wall reinforced pipe production equipment includes a laterally movable carriage 1, and the carriage 1 is provided with a horizontally facing and can be positioned with both ends of the tube blank 9 respectively. The movable die head 102, the fixed die head 2, the movable die head 26 and the fixed die head 27 can all be driven to rotate by a rotating motor.

[0040] Specifically, as Figure 1-5 As shown, one side of the carriage 1 is provided with an extruder 3, and the fixed touch head 2 includes a rotatable base 23 and a cylindrical support 22 connected to the base 23. The support 22 has an inner wall that can support the tube blank 9. The small-diameter end 22c and the large-diameter end 22b that can be placed on the outer cladding layer 101, the diameter of the large-diameter end 22b is larger than the diameter of the small-diameter end 22c, and the small-diameter end 22c is locate...

Embodiment 2

[0048] The content of this embodiment is basically the same as that of the first embodiment, and the difference lies in:

[0049] The support is a radially shrinkable mesh frame, and the mesh frame is connected to the jaws 21 a of the three-jaw chuck 21 .

[0050] The grid can be radially retracted with the movement of the jaws 21a, which can further improve the support for the outer cladding layer 101 and the tensioning and positioning of the tube blank 9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com