Device and method for synthesizing 3, 5-dimethylphenol by electromagnetic heat supply method

A dimethylphenol, electromagnetic heating technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry and other directions, can solve the problems of low yield and selectivity, difficult to clean coke, etc. The effect of fast vaporization and high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

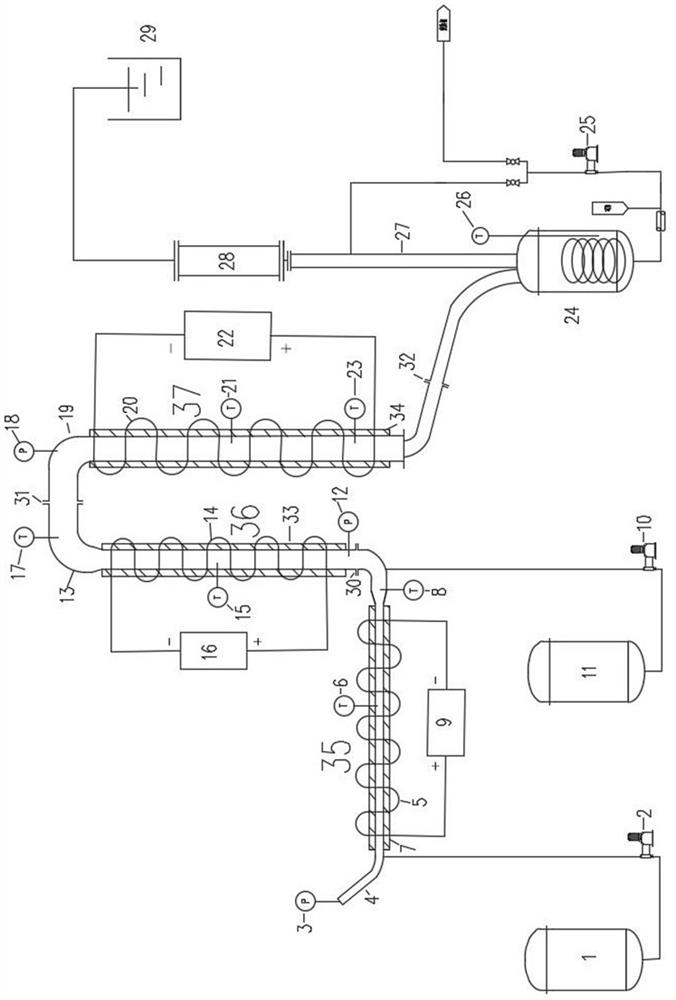

Method used

Image

Examples

Embodiment 1

[0043] Weigh 100kg of isophorone, load into the raw material tank, take by weighing 1,2-dibromoethane and methyl iodide ratio to be 5:1 catalyst 1kg is loaded into the catalyst tank, and is injected into the reaction device by plunger pump section, During the process, the outlet temperature of the vaporization tube is controlled to be 430°C-450°C, the outlet temperature of the preheating tube is 480°C-500°C, the temperature of the cracking tube outlet is 540°C-550°C, the feed rate of the raw material is 200g / min, and the feed rate of the catalyst is 4g / min; the cracked gas enters the caustic washing tower kettle after being condensed by the alkaline washing tower and the condenser, and the upper organic phase is the crude 3,5-dimethylphenol. The non-condensable gas methane is evacuated after passing through the tail gas water sealing device. The organic phase was analyzed by gas phase detection results, and it was found that the conversion rate of isophorone was 100%, the sel...

Embodiment 2- Embodiment 8

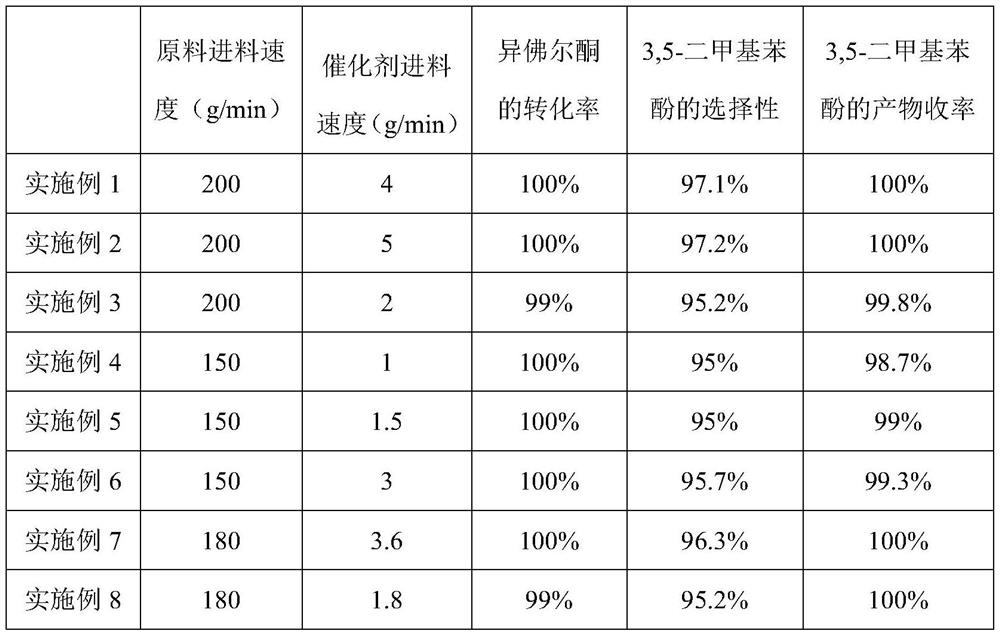

[0045] Example 2-Example 8 are generally similar to Example 1, the catalyst dosage and feed rate in Example 1 are adjusted, and the remaining steps are identical to Example 1. The details of Example 2-Example 8 are as follows:

[0046]

[0047] The conversion of the obtained isophorone and the selectivity and yield of 3,5-dimethylphenol are shown in the table above.

Embodiment 9- Embodiment 11

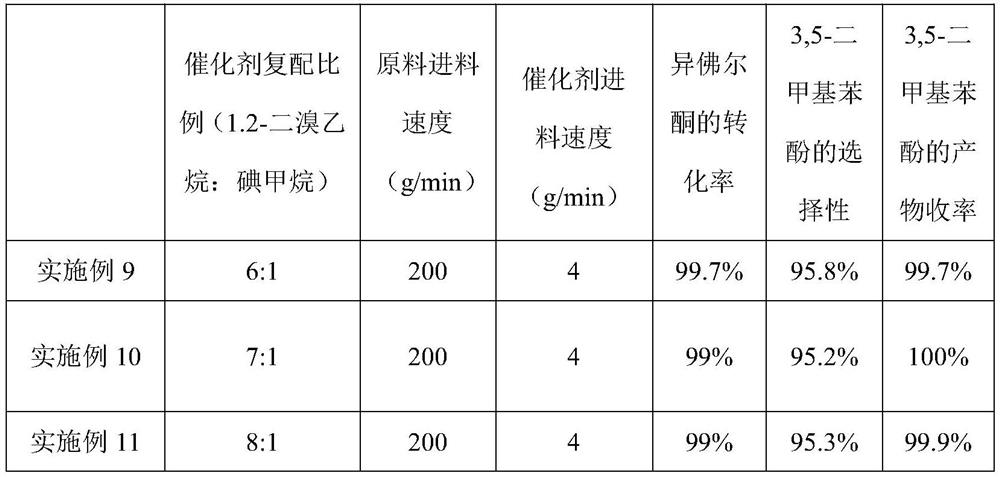

[0049] Change the catalyst compounding ratio in Example 1, and the remaining steps are equivalent to Example 1, respectively obtain Example 9-Example 11:

[0050]

[0051] The conversion of the obtained isophorone and the selectivity and yield of 3,5-dimethylphenol are shown in the table above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com