Industrial chimney ladder stand detection equipment

A detection equipment and ladder-climbing technology, which is applied in the field of industrial chimney ladder detection equipment, can solve problems such as ladder breakage, difficult operation, and safety accidents, and achieve the effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

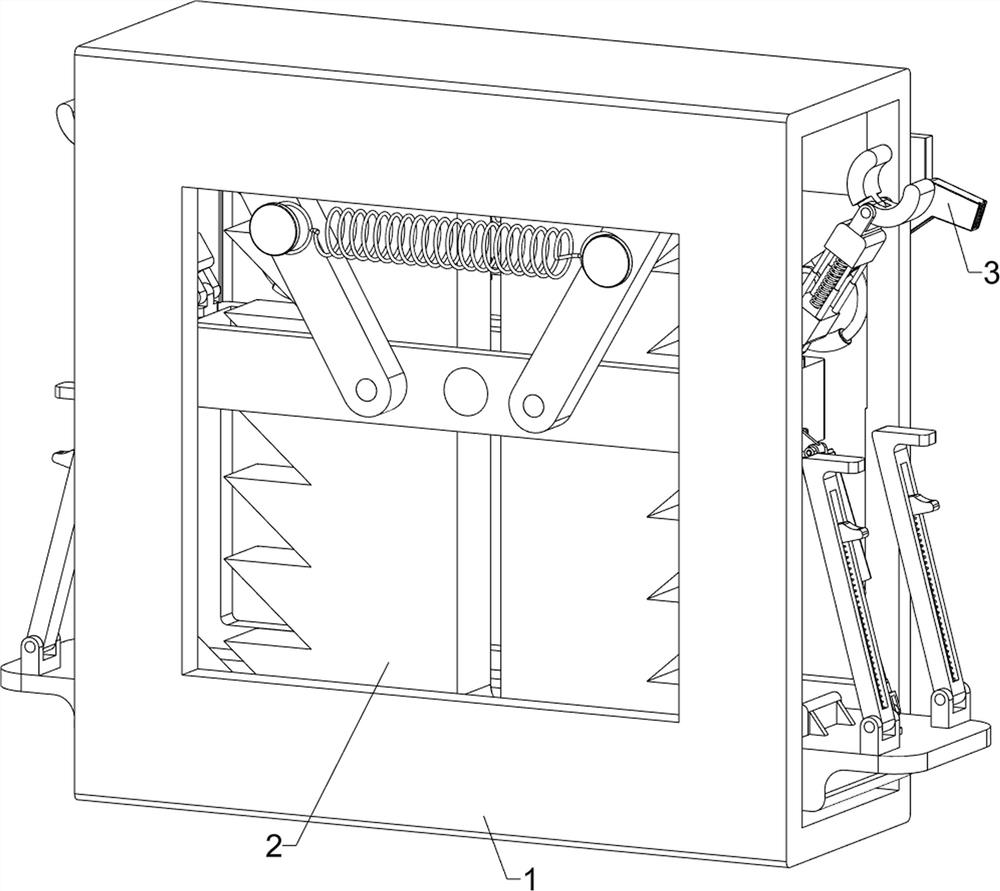

[0031] An industrial chimney climbing ladder detection equipment, such as Figure 1-10 As shown, it includes an installation frame 1, a detection system 2 and a marking system 3; a detection system 2 is installed inside the installation frame 1; a marking system 3 is connected to the front of the detection system 2.

[0032] First, the staff moves and fixes the industrial chimney ladder detection equipment on the chimney ladder, and then controls the detection system 2 to drive the industrial chimney ladder detection equipment to move up, and at the same time, detects the ladder on the chimney. When the side of the ladder on the chimney is detected When broken, the linkage marking system 3 marks the damaged parts at the same time, which is convenient for maintenance personnel to repair.

Embodiment 2

[0034] On the basis of Example 1, as Figure 1-10As shown, the detection system 2 includes a telescopic plate 201, a first bearing seat 202, a sliding frame 203, a first elastic member 204, a first limit block 205, a first electric push rod 206, a wedge block 207, a toothed plate 208, Fixed frame 209, sliding rod 2010, first connecting plate 2011, limit shaft 2012, second elastic member 2013, limit rod 2014, second bearing seat 2015, telescopic rod 2016 and electric clip 2017; the internal fixation of installation frame 1 A toothed plate 208 is connected; a through chute is set on the toothed plate 208, and a sliding rod 2010 is slidably connected in the through chute; The lower part of 209 is hinged with two left-right symmetrical first electric push rods 206; the telescopic ends of the two first electric push rods 206 are hinged with a telescopic plate 201; the upper surface of the telescopic plate 201 is fixedly connected with four rectangularly distributed The first beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com