Lens quality detection device for medical endoscope production

A detection device and endoscope technology, applied in the direction of testing optical performance, etc., can solve the problems of complicated operation, collision operation, time-consuming and laborious disassembly, etc., and achieve the effect of saving time and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific content of the present invention will be further explained in detail below in conjunction with the examples, but it is not intended to limit the present invention.

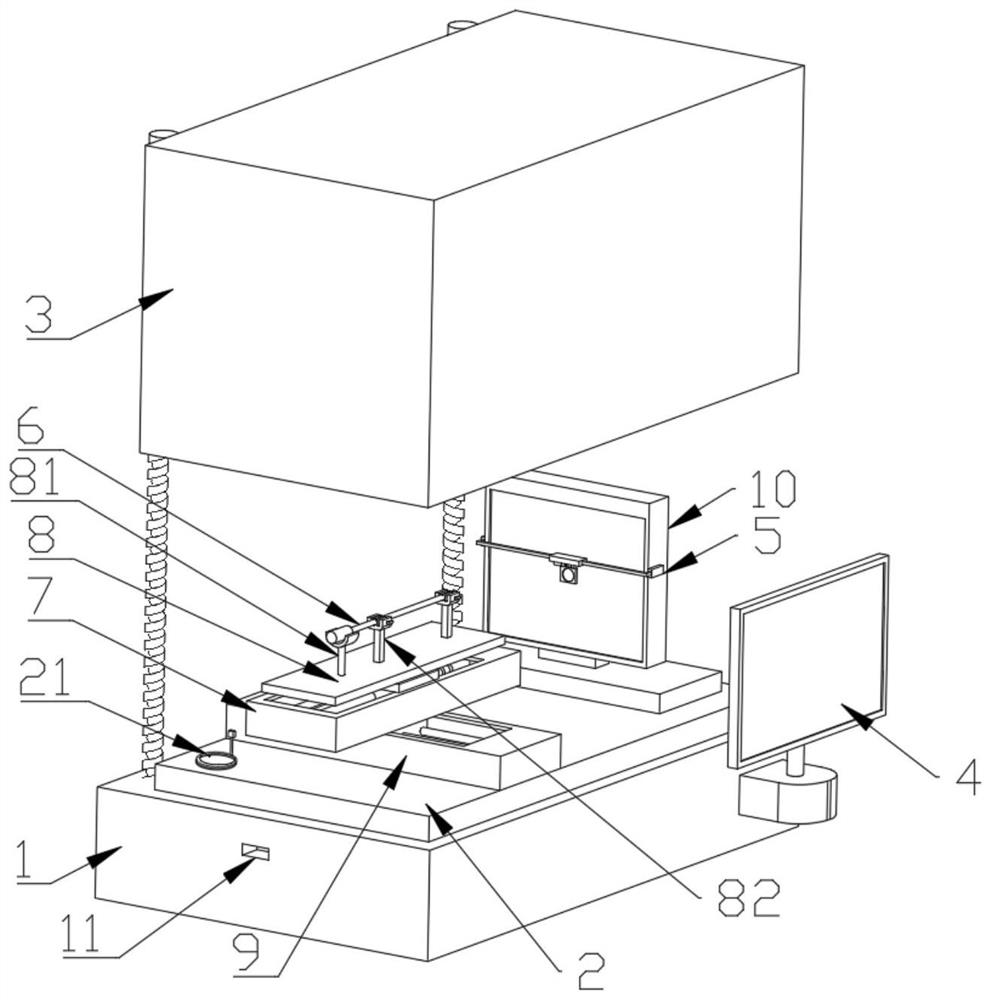

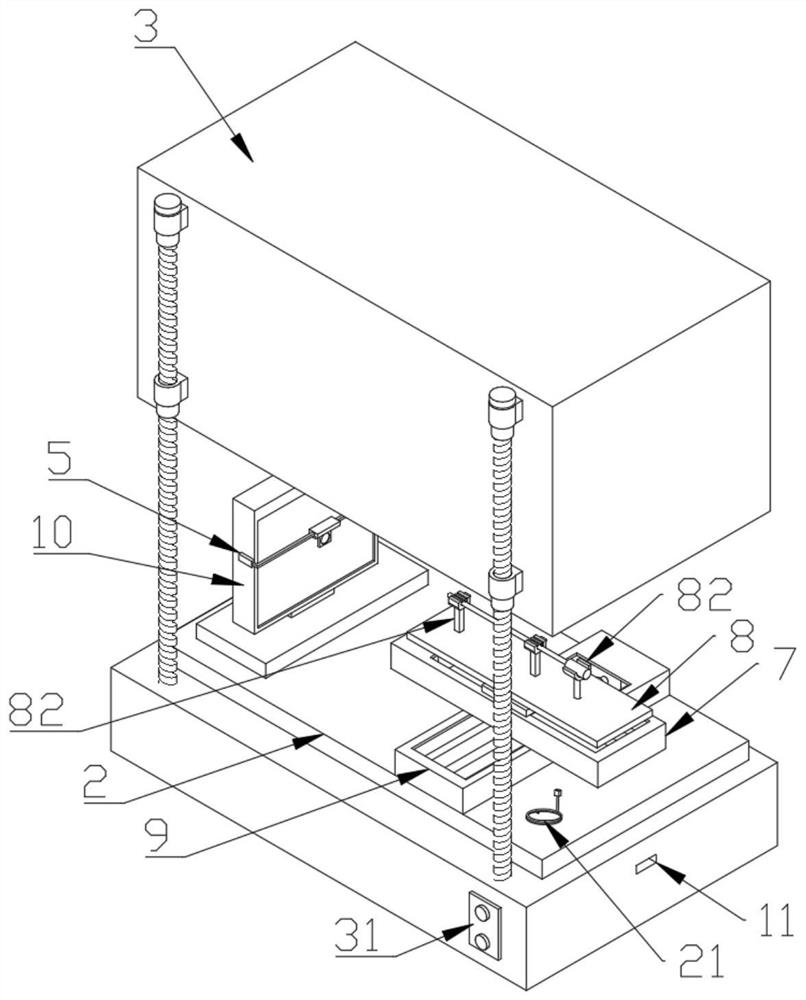

[0035] like figure 1 , figure 2 As shown, the medical endoscope production lens quality inspection device includes a main body 1 , a test endoscope lens 6 and a PLC controller 4 .

[0036] A drive dark box device 3 is installed on one side of the upper end of the main body 1, specifically, as Image 6 As shown, the driving dark box device 3 includes several lifting mechanisms 32 , a dark box body 33 , a lifting controller 31 for controlling the dark box body 33 , and the dark box body 33 is installed on the main body 1 through the lifting mechanism 32 .

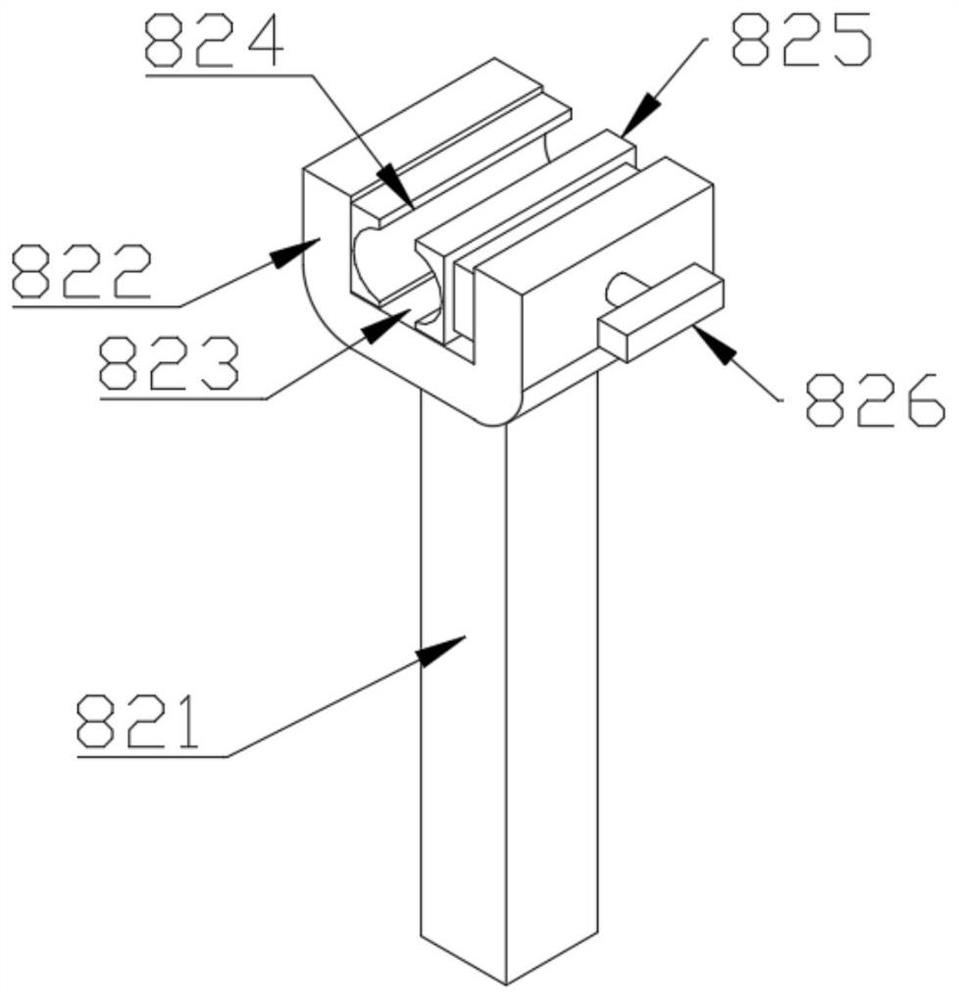

[0037] The lifting mechanism 32 includes a first threaded rod 322 and a first servo motor 323. The first servo motor 323 is installed inside the main body 1, and the first threaded rod 322 penetrates the main body 1 and the first servo moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com