Explosive filling device and explosive filling method

A filling device and a technology for explosives, which are applied in the field of explosives filling, can solve the problems of deviation and difference in preset values, and the blasting effect cannot be effectively guaranteed, and achieve the effect of improving the blasting effect and increasing the accuracy of the dosage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present application will be further described in detail below with reference to the accompanying drawings.

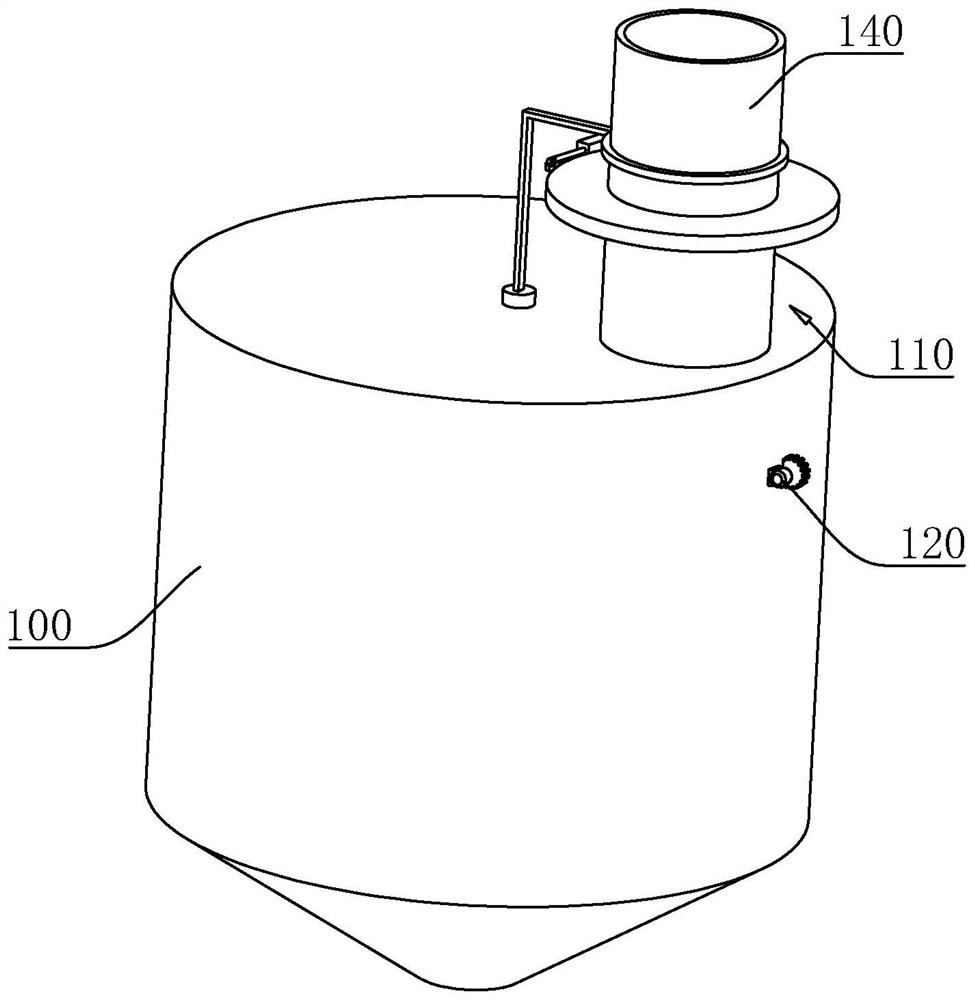

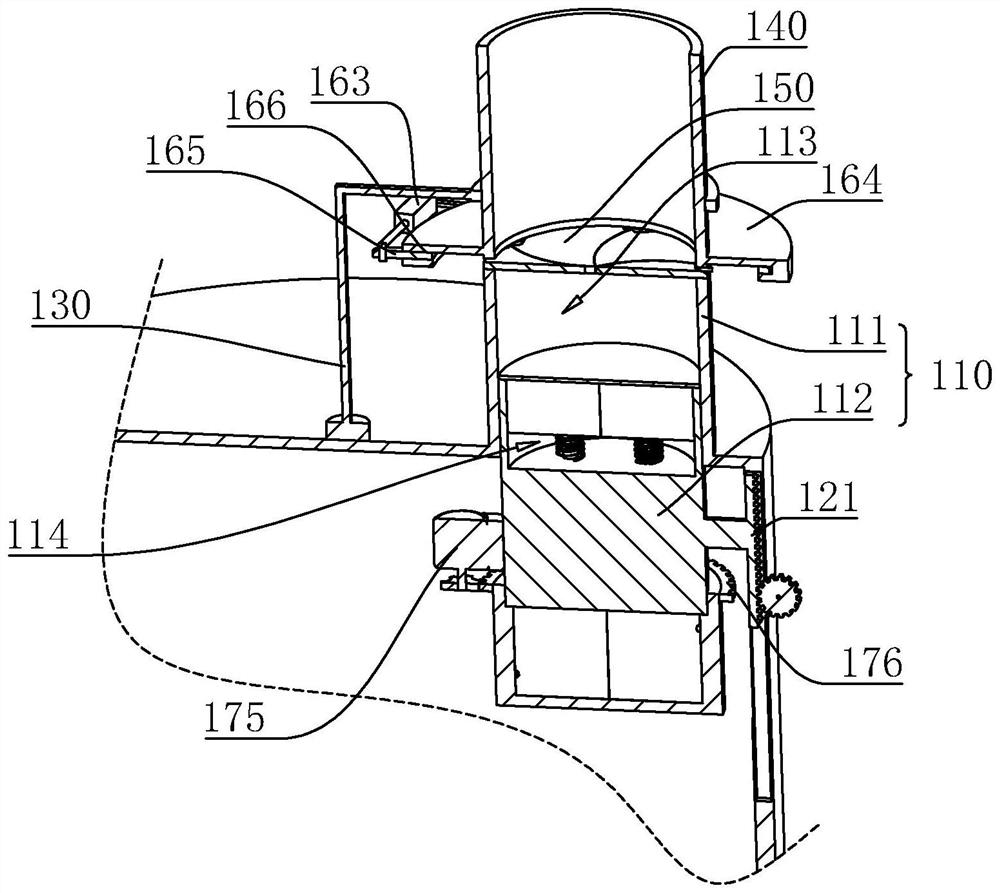

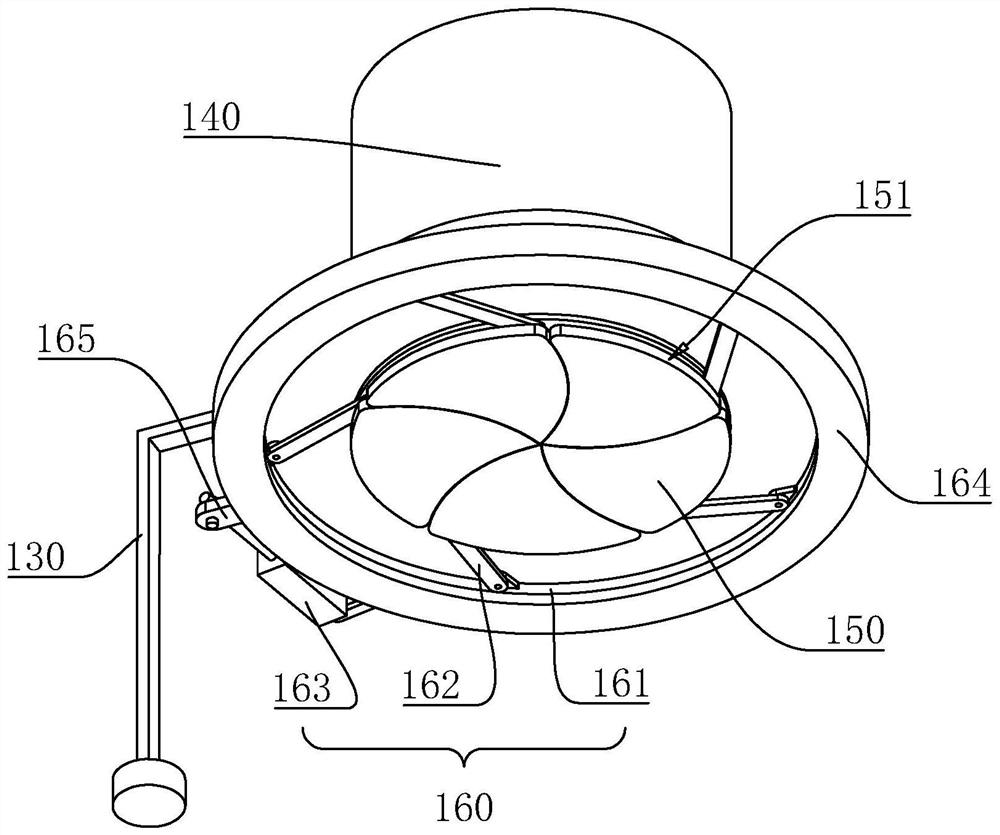

[0044] The embodiment of the present application discloses an explosive loading device, refer to figure 1 , figure 2 , including a filling bin 100, the filling bin 100 is connected with a filling pipe 110, and the lower part of the filling bin 100 is connected to a filling port. The filling pipe 110 includes an outer sleeve 111 arranged on the upper side of the filling chamber 100, a quantitative column 112 connected in the outer sleeve 111 along the axial sliding direction, and the outer sleeve 111 is eccentrically arranged and vertically connected to the upper side of the filling chamber 100, The packing chamber 100 is provided with a driving member for driving the quantitative column 112 to move, and a pre-packing cavity 113 is formed between the top of the outer casing 111 and the top of the quantitative column 112 .

[0045]In this embodiment, the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com