Composite low-temperature negative-pressure dividing wall type heat exchanger for refrigerating machine in extremely low-temperature area

A technology of low-temperature negative pressure and heat exchanger, which is applied in the field of refrigeration and low-temperature engineering, JT refrigerators, can solve problems that need to be further improved, and achieve the effect of compact structure, ensuring heat exchange, and improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In the following description, numerous technical details are set forth in order to provide the reader with a better understanding of the present application. However, those of ordinary skill in the art can understand that even without these technical details and various changes and modifications based on the following embodiments, the technical solutions claimed in the present application can be realized.

[0042]Some innovative points of the embodiments of the present application are briefly described below:

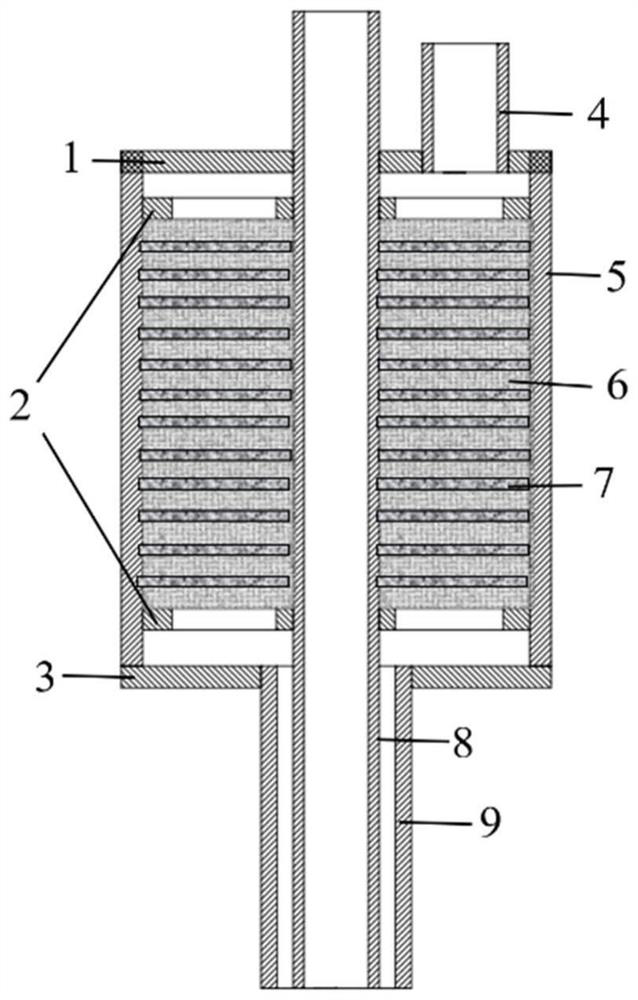

[0043] After long-term research, the inventor of the present application creatively proposes a composite low-temperature negative pressure device for an extremely low-temperature zone refrigerator in view of the technical problem that the efficiency of the low-temperature negative pressure partition wall heat exchanger in the prior art still needs to be further improved. Divider wall heat exchanger, including: upper top cover, baffle plate, lower top cover, high ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com