Preparation process of large balancing weight for gravity energy storage made of engineering residue soil

A preparation process, technology of engineering dregs, applied in the field of preparation of large-scale counterweights for gravity energy storage made of engineering dregs, which can solve the problems of insufficient compactness of the lower part of the product, high cost of concrete, and deformation of the product due to mold leakage , to achieve the effect of improving the effective utilization of resources, reducing solid waste emissions, and ensuring the accuracy of external dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

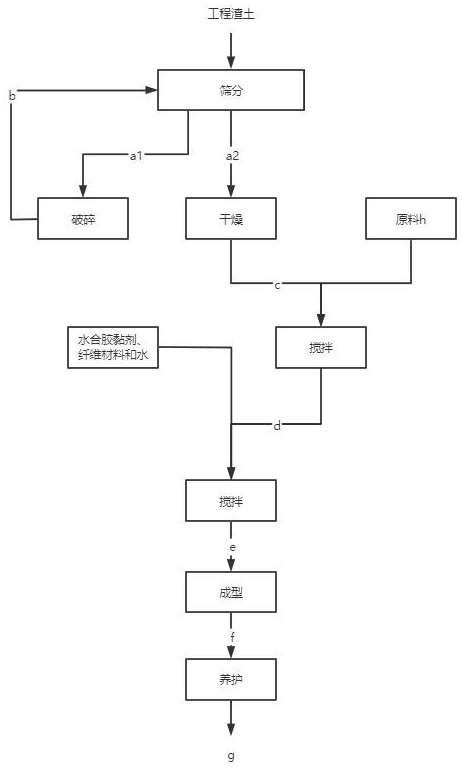

[0052] (1) Screening process: The waste engineering slag is screened through a circular vibrating screen with a diameter of 10 mm to obtain product a1 and product a2;

[0053] (2) Crushing process: crushing product a1 through a roller press to obtain product b;

[0054] (3) Circulation process: mix the product b into the engineering slag, and repeat the operations of steps (1) and (2);

[0055] (4) Drying process: the product a2 is dried in the open air for 7 days to obtain the product c;

[0056] (5) Mixing and stirring process: product c is mixed with high-strength cement, recycled fine aggregate, and high-quality steel slag powder in a ratio of 40:15:30:15, and product d is obtained after stirring evenly;

[0057] (6) batching process: after mixing product d with 0.04% hydrated adhesive and fiber material, add water and stir to obtain product e with a moisture content of 8%;

[0058] (7) Injection process: inject the product e into the injection bin of the molding equipme...

Embodiment 2

[0063] (1) Screening process: the waste engineering slag is screened through a circular vibrating screen with a diameter of 5 mm to obtain product a1 and product a2;

[0064] (2) Crushing process: crushing product a1 through a roller press to obtain product b;

[0065] (3) Circulation process: mix the product b into the engineering slag, and repeat the operations of steps (1) and (2);

[0066] (4) Drying process: the product a2 is dried in the open air for 8 days to obtain the product c;

[0067] (5) Mixing and stirring process: product c is mixed with high-strength cement and recycled fine aggregate in a ratio of 5:2:3, and product d is obtained after stirring evenly;

[0068] (6) batching process: after mixing product d with 0.05% hydrated adhesive and fiber material, adding water and stirring to obtain product e with a moisture content of 10%;

[0069] (7) Injection process: inject the product e into the injection bin of the molding equipment through the conveyor belt;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com