Disk shear tool changing opportunity prediction system and method based on shear blade wear detection

A prediction system and prediction method technology, applied in manufacturing computing systems, still image data retrieval, digital data information retrieval, etc. Inaccurate prediction or determination of sharpening, high cost of disc cutter maintenance and scrapping, to achieve automatic learning, reduce workload, and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] An expert system for wear detection and tool change timing prediction of disc scissors, including a detection system and an expert system.

[0087] The inspection system includes a high-precision high-speed industrial camera, a rack, an image storage platform and an image processing platform; the disc shear is not static but is always in a state of rotation around the axis. Using a high-precision high-speed camera can obtain ideal image effects. The camera is installed on the outer side of the disc scissors through the rack, and the blade part of the disc scissors is photographed, and the obtained pictures are stored in the image storage platform. Feature extraction is performed between the captured image and the original image, the difference between the two is obtained, and the wear amount of the current disc scissors is calculated in combination with the shooting angle.

[0088] The expert system consists of six parts, including the interactive interface, knowledge b...

Embodiment 2

[0097] According to the disc scissors tool change timing prediction expert system for wear detection, the invention extracts and analyzes the wear amount of the disc scissors tool at different processing times, and uses the neural network algorithm to fit the tool wear amount-steel excess curve. And analyze the tool's follow-up time threshold:

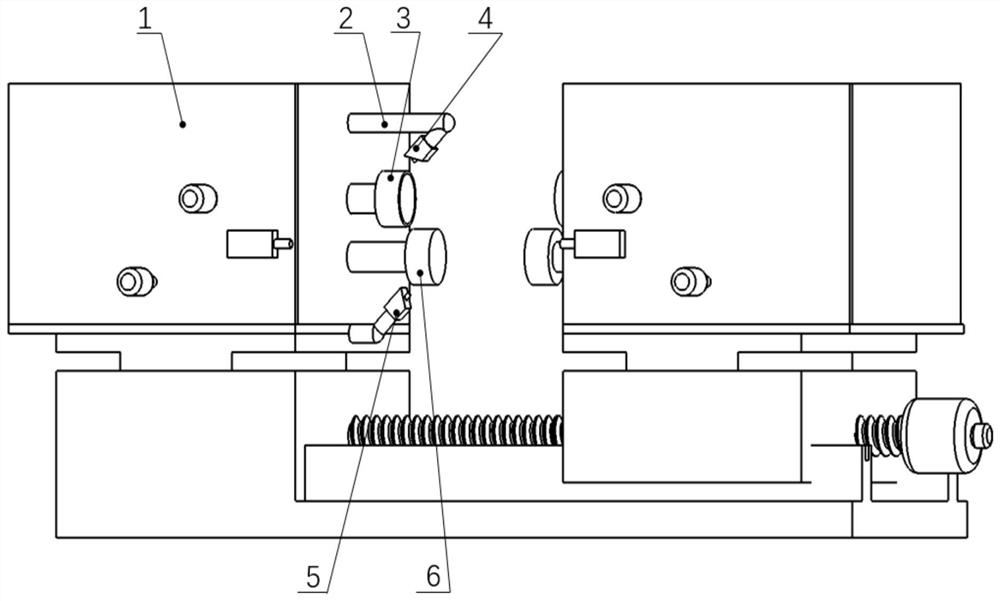

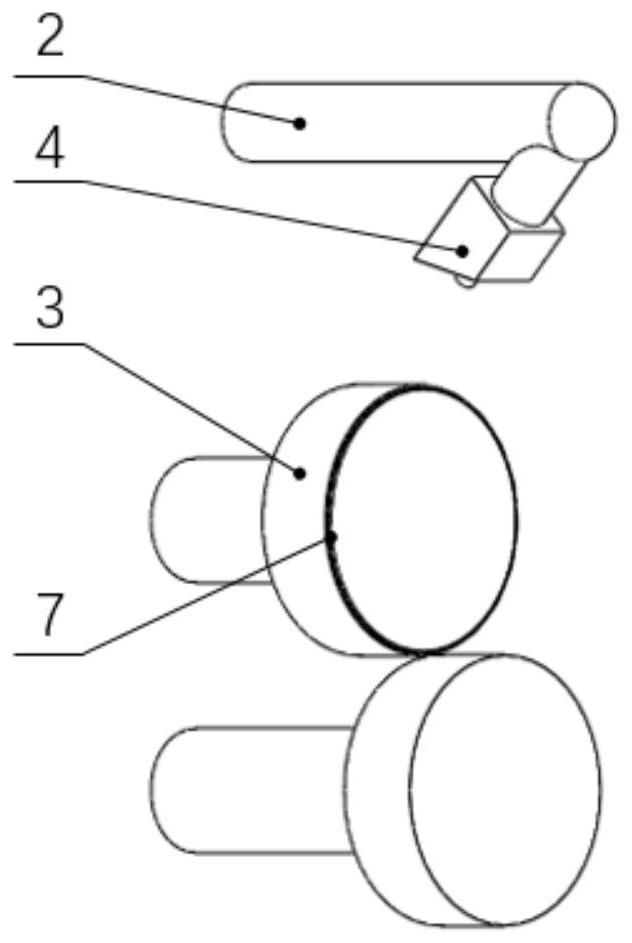

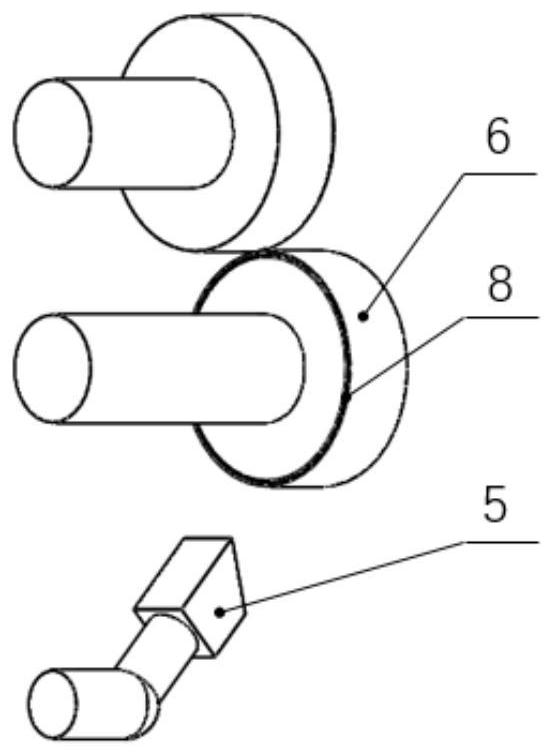

[0098] 1. During the cutting process of the disc shear 1, the upper cutter disc 3 is pressed down to cut the plate, and the upper cutter disc cutting surface 7 and the lower cutter disc cutting surface 8 which are in contact with the strip are the most easily worn. The increase in shear force will lead to the phenomenon of tool chipping, such as figure 1 . In view of this situation, use the YVSION first high-precision industrial camera 4 and the second high-precision industrial camera 5 installed on the rack 2 to take pictures of the worn parts of the disc scissors, such as figure 2 shown. The lens specification is 640*480 790 fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com