Power protection device plug-in batch automatic test system

An automatic test system and power protection technology, applied in the field of power protection equipment, can solve problems such as poor compatibility, various types, and implementation difficulties, and achieve the effects of good compatibility and stability, easy networking, and good test results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

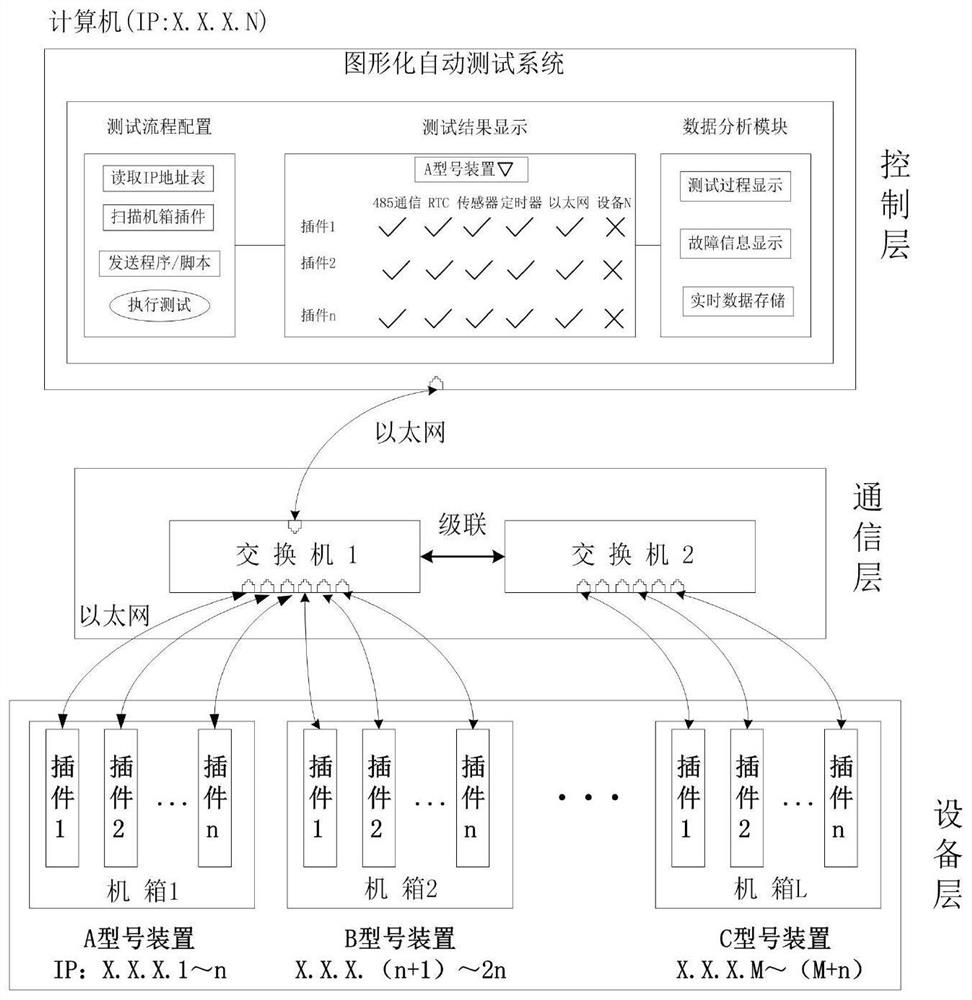

[0041] This embodiment introduces a batch automatic testing system for plug-ins of power protection devices. The whole system can be simplified into three layers: control layer, communication layer, and equipment layer. figure 1 The equipment layer is mainly composed of a series of tested chassis and test plug-ins; the chassis stores plug-ins belonging to this type of device, and can store multiple plug-ins (the number is determined according to the size of the chassis). Taking chassis 1 as an example, all the plug-ins of type A are loaded in the chassis. In order to realize the unified control of plug-ins, a fixed IP address is assigned to the network ports of each plug-in, and they belong to the same network segment, and n blocks of plug-ins correspond to The IP address of the device is X.X.X.1~X.X.X.n in sequence, and the plug-ins in the range of 1-n belong to the A-type device, that is to say, the IP address can uniquely identify the device model and the plug-in model, such...

Embodiment 2

[0055] This embodiment provides a method for testing a power protection device plug-in batch automatic test system according to any one of Embodiment 1, which is applied to the control layer, including:

[0056] By reading the IP address table module, enter the mapping table of IP and plug-in information;

[0057] By scanning the plug-in module of the chassis, obtain the IP address that can be communicated, and display the plug-in information and the number of existing plug-ins at the device layer according to the mapping relationship table between IP and plug-in information;

[0058] Transmit one or more of test program and script information to each plug-in in turn through Ethernet;

[0059] Send a unified contract message to the device layer to start the test program inside each plug-in, wherein the device layer returns the test information and test results to the control layer in real time;

[0060] Obtain test information and test results returned by the device layer, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com