Large-span prefabricated frame structure support-free structure and construction method

A frame structure and support structure technology, applied in building construction, building material processing, construction, etc., can solve problems such as prolonging the construction period, and achieve the effects of precise positioning, favorable for popularization and application, and high installation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

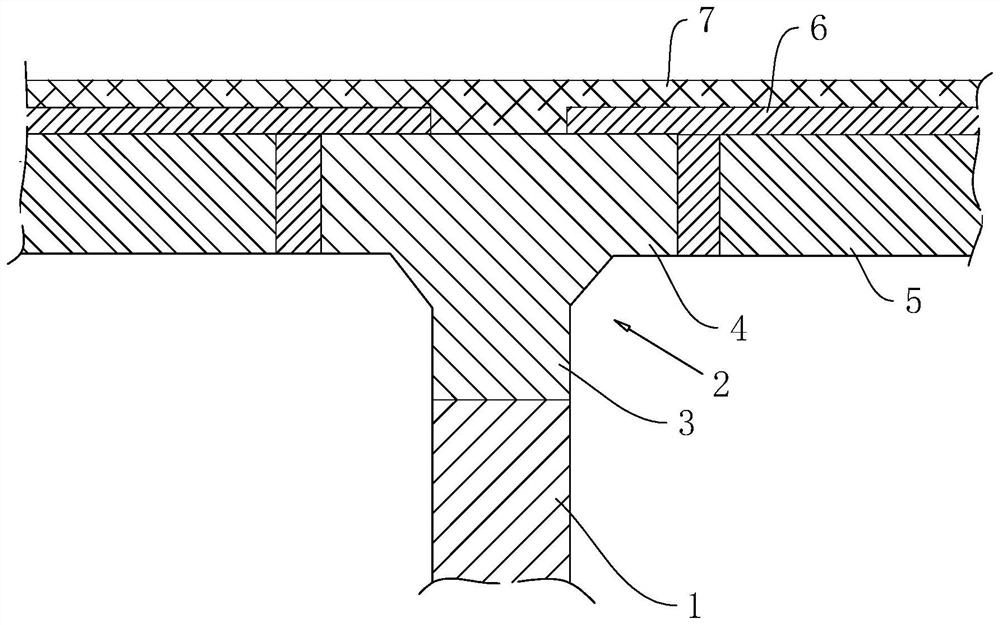

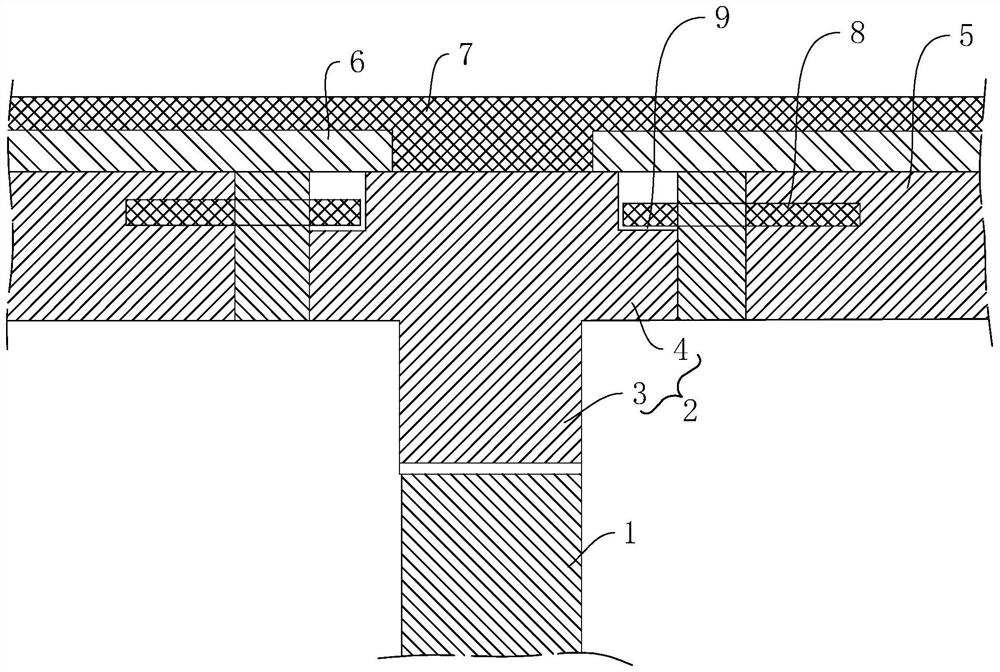

[0037] Attached to the following Figure 1-5 This application will be described in further detail.

[0038] In a first aspect, an embodiment of the present application discloses a large-span prefabricated frame structure without support.

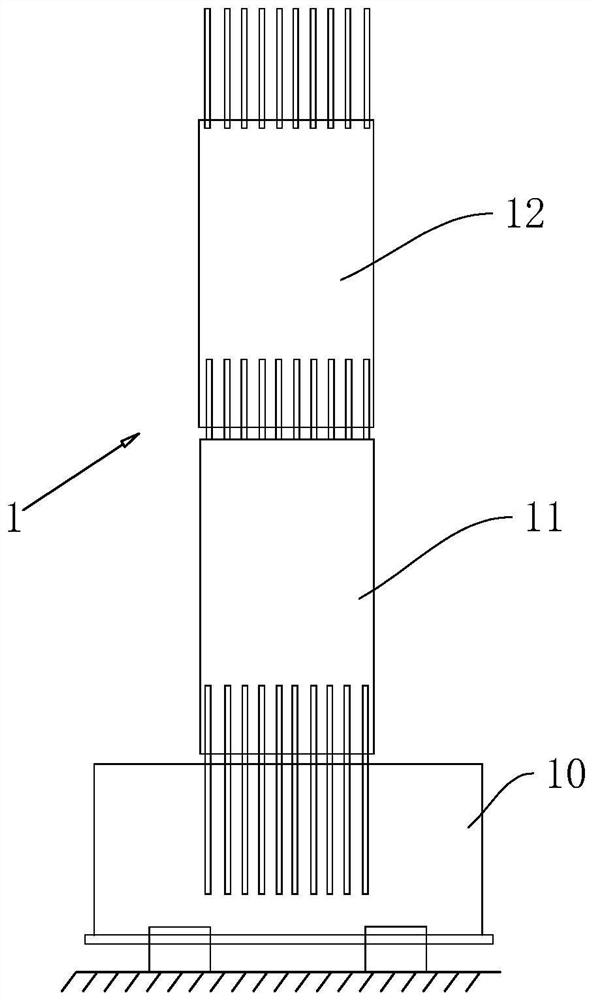

[0039] refer to figure 1 , a large-span prefabricated frame structure without support, including pillars 1 formed on the ground. The pillars 1 can be formed by prefabrication or cast-in-place. In this embodiment, the pillars 1 include prefabricated pillars. The cement cap 10 casted on the ground, the lower column 11 and the upper column 12, the lower column 11 and the upper column 12 are all prefabricated columns, and the lower column 11 is pre-fixed on the upper surface of the cap 10 , the bottom end of the lower column 11 and the protruding steel bars on the upper surface of the platform 10 are staggered and welded to each other. At the same time, C60 mortar is poured between the lower column 11 and the platform 10, and the pouring thick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com