Processing method of inferior heavy oil

A low-quality heavy oil and processing method technology, which is applied in the petroleum industry, hydrotreating process, and hydrocarbon oil treatment, can solve the problems of low efficiency and low utilization of alkali metals, and achieve extended operation cycle, favorable contact, and accelerated separation effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-2

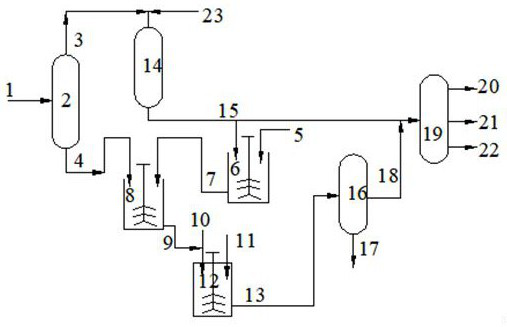

[0043] The raw oil is separated into light distillate raw materials and heavy distillate raw materials through the fractionation tower at 360 ° C as the cutting point; the light distillate raw materials and hydrogen enter the hydrotreating unit, and undergo hydrodesulfurization and hydrodenitrogenation under mild operating conditions. Wait for the hydrotreating reaction to obtain the oil produced by hydrotreating; the heavy distillate raw materials and sodium metal enter the stirring reactor, and undergo hydrodeoxygenation, hydrodemetallization, hydrodesulfurization and other reactions under the action of hydrogen, and the obtained materials undergo After separation by the cyclone separator, liquid-phase products, solid mixtures such as sodium sulfide and metals are obtained; the liquid-phase products and the oil produced by hydroprocessing enter the fractionation tower for fractionation to obtain naphtha, diesel oil, wax oil and other products.

Embodiment 3-4

[0045] The raw oil is separated into light distillate raw materials and heavy distillate raw materials through a fractionation tower at 375 °C. Wait for the hydrotreating reaction to obtain hydrotreating oil; part of the hydrotreating oil, aluminum tripolyphosphate and silicon phosphate curing agent (ratio 3:4:4) are stirred and mixed in a stirring tank to obtain a modified hydrotreating oil. The oil produced by hydroprocessing is mixed with the heavy distillate raw material in a stirred tank to prepare the heavy distillate raw material, wherein the ratio of the modified hydrotreated oil to the heavy distillate raw material is 1:9; the heavy distillate raw material and the metal sodium are mixed together The reactor is used for hydrodeoxygenation, hydrodemetallization, hydrodesulfurization and other reactions under the action of methane. The obtained materials are separated by a cyclone to obtain liquid-phase products, solid mixtures such as sodium sulfide and metals; liquid-ph...

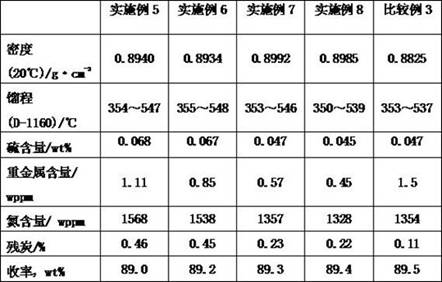

Embodiment 5-6

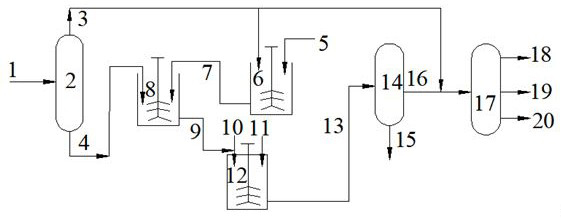

[0060] The raw oil is separated into light distillate raw materials and heavy distillate raw materials through a fractionation tower at 360 °C as the cutting point; Hydrodesulfurization and other reactions, the obtained materials are separated by a cyclone separator to obtain liquid-phase products, solid mixtures such as sodium sulfide and metal; and other products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dry point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com