Super-hydrophobic self-cleaning temperature-adaptive radiation cooling coating and coating preparation method

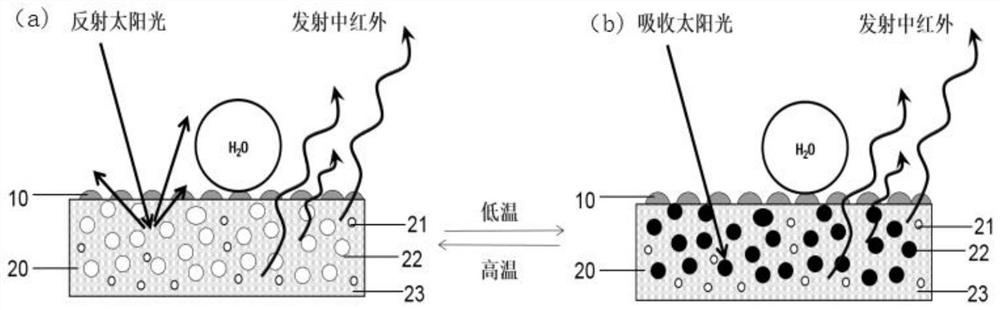

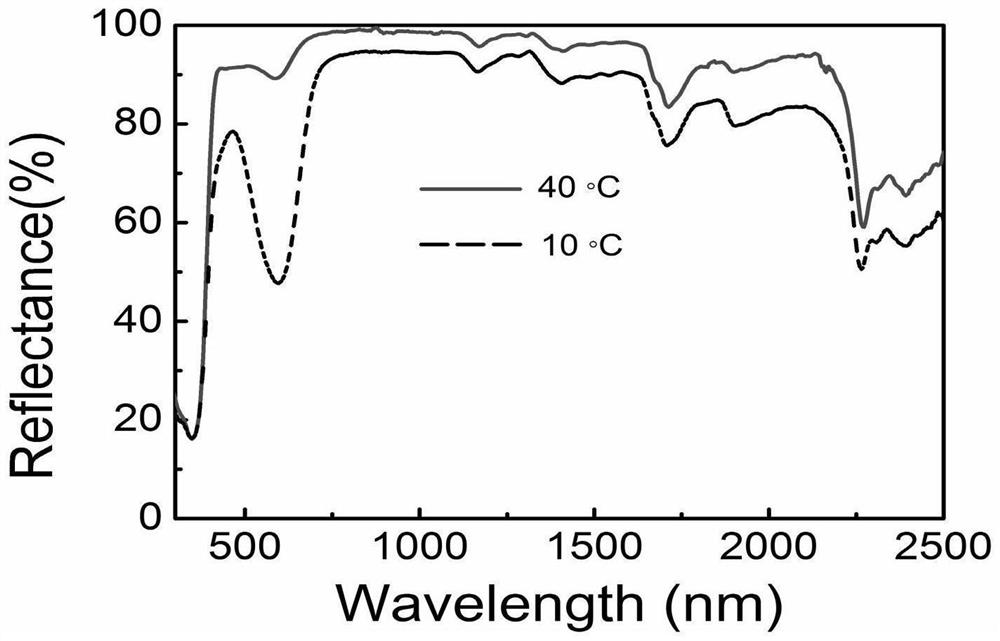

A self-cleaning, super-hydrophobic technology, applied in radiation-absorbing coatings, coatings, reflective/signal coatings, etc., can solve the problems of not considering the influence of material cooling or heating effects, unfavorable architectural applications, and high packaging requirements, and achieve savings The effect of power resources, global warming mitigation, and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of the superhydrophobic self-cleaning temperature adaptive radiation cooling coating of the present invention comprises the following steps:

[0029] Step 1, combine P(VDF-HFP), hydrophobic SiO 2 , Mix the blending agent (the blending agent 23 includes anti-ultraviolet absorber, light stabilizer, antioxidant) in the solvent acetone and stir at room temperature for 3 to 5 hours to uniformly disperse to form an organic-inorganic composite dispersion;

[0030] The mass ratio of P(VDF-HFP) to acetone is 1:(8~10), P(VDF-HFP) to hydrophobic SiO 2 The mass ratio is 2:(0.1~0.26), the content of anti-ultraviolet absorber is 0.5%~3%, the content of light stabilizer is 0.5%~3%, and the content of antioxidant is 0.5%~3%.

[0031] The mass ratio of P(VDF-HFP) to acetone is 1:(8~10), P(VDF-HFP) to hydrophobic SiO 2 The mass ratio is 2:(0.1~0.26), the content of anti-ultraviolet absorber is 0.5%~3%, the content of light stabilizer is 0.5%~3%, and the content o...

Embodiment 1

[0041] The preparation method of the superhydrophobic self-cleaning temperature adaptive radiation cooling coating of the present invention comprises the following steps:

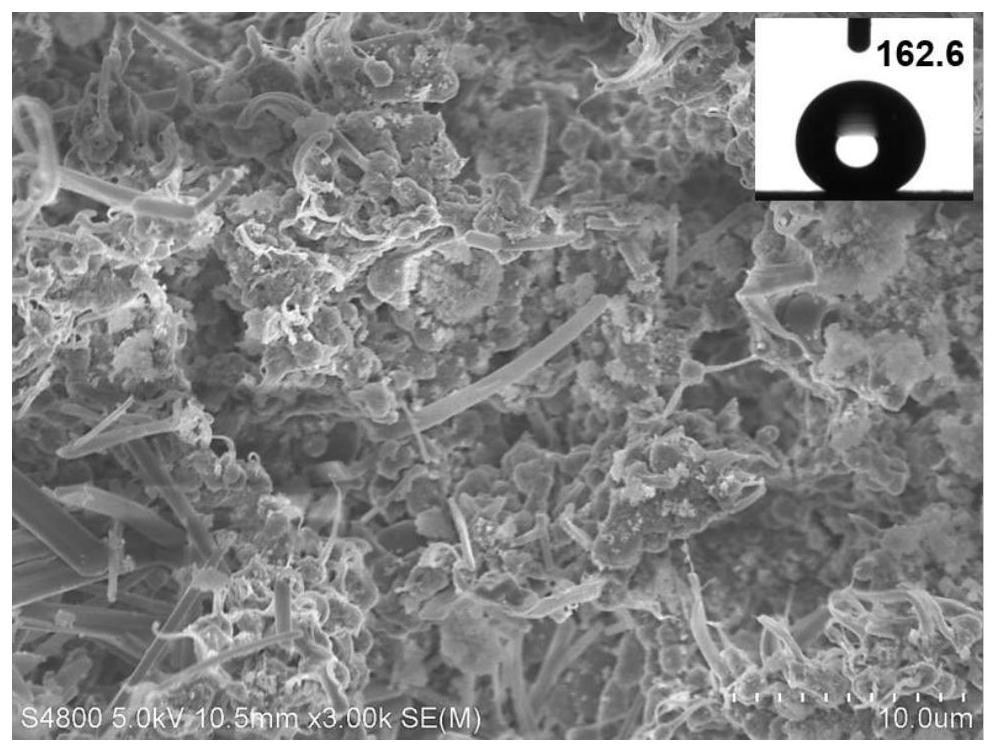

[0042] Step 1, first weigh 2.0g of P(VDF-HFP) and 0.1g of hydrophobic SiO 2 , 0.06g of anti-ultraviolet absorber, 0.06g of light stabilizer, and 0.06g of antioxidant were dissolved in 17g of acetone solution, and stirred at room temperature for 3.5h to mix uniformly to obtain an organic-inorganic composite dispersion liquid, for use;

[0043] Step 2: Weigh 0.08 g of blue thermochromic phase change microcapsules and disperse them in 8.8 g of water, stir at room temperature for 15 min until uniformly mixed to obtain a dispersion of thermochromic phase change microcapsules, for use;

[0044] Step 3, adding 2.2g of thermochromic phase change microcapsule dispersion liquid dropwise to the organic-inorganic composite dispersion liquid at a rate of dropping 0.05ml every 15s into the organic-inorganic composite dis...

Embodiment 2

[0048] The preparation method of the superhydrophobic self-cleaning temperature adaptive radiation cooling coating of the present invention comprises the following steps:

[0049] Step 1, weigh 2.0g of P(VDF-HFP), 0.18g of hydrophobic SiO 2 , 0.01g of anti-ultraviolet absorber, 0.01g of light stabilizer, and 0.01g of antioxidant were dissolved in 16g of acetone solution, and stirred at room temperature for 3h to mix uniformly to obtain an organic-inorganic composite dispersion, for use;

[0050] Step 2: Weigh 0.32 g of red thermochromic phase change microcapsules and disperse them in 10.4 g of water, stir at room temperature for 15 min until uniformly mixed to obtain a dispersion of thermochromic phase change microcapsules, which is for later use;

[0051] Step 3, adding 2.6g of thermochromic phase change microcapsule dispersion liquid dropwise to the organic-inorganic composite dispersion liquid at a rate of dropping 0.05ml every 15s into the organic-inorganic composite dispe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com