Bus duct power distribution system and bus duct production process

A power distribution system and busbar technology, applied in cooling busbar devices, fully enclosed busbar devices, etc., can solve the problems of poor heat dissipation capacity of busbar conductors, low current carrying capacity of conductors, and poor mechanical strength, etc., to improve ventilation and heat dissipation. effect, reducing heat build-up, increasing mechanical strength and the effect of ductile surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

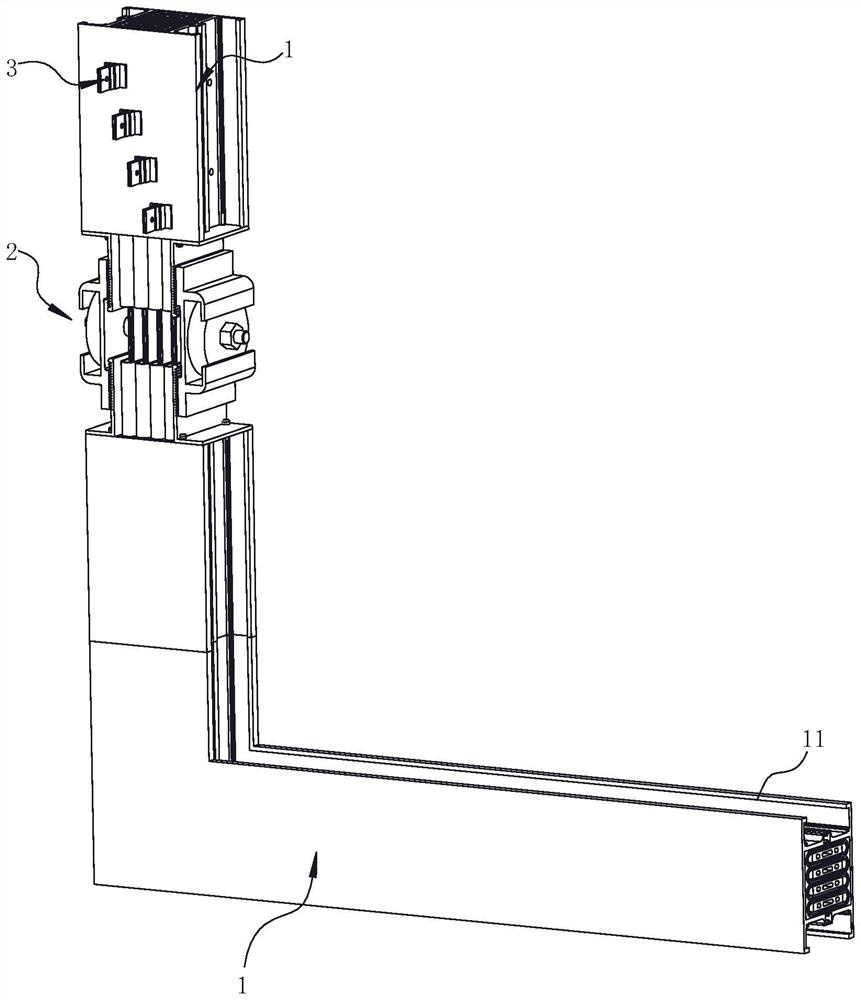

[0054] The embodiment of the present application discloses a busbar trunking power distribution system. refer to figure 1 , a bus duct power distribution system includes a plurality of interconnected bus ducts 1, a connector 2 for connecting the bus duct 1, and a connector 3 for electrically connecting the bus duct 1 with external equipment. The connector 2 can By connecting two busbar ducts 1 separated from each other, the current of the busbar duct 1 can be connected to an external device through the plug connector 3, so as to supply power to the external device.

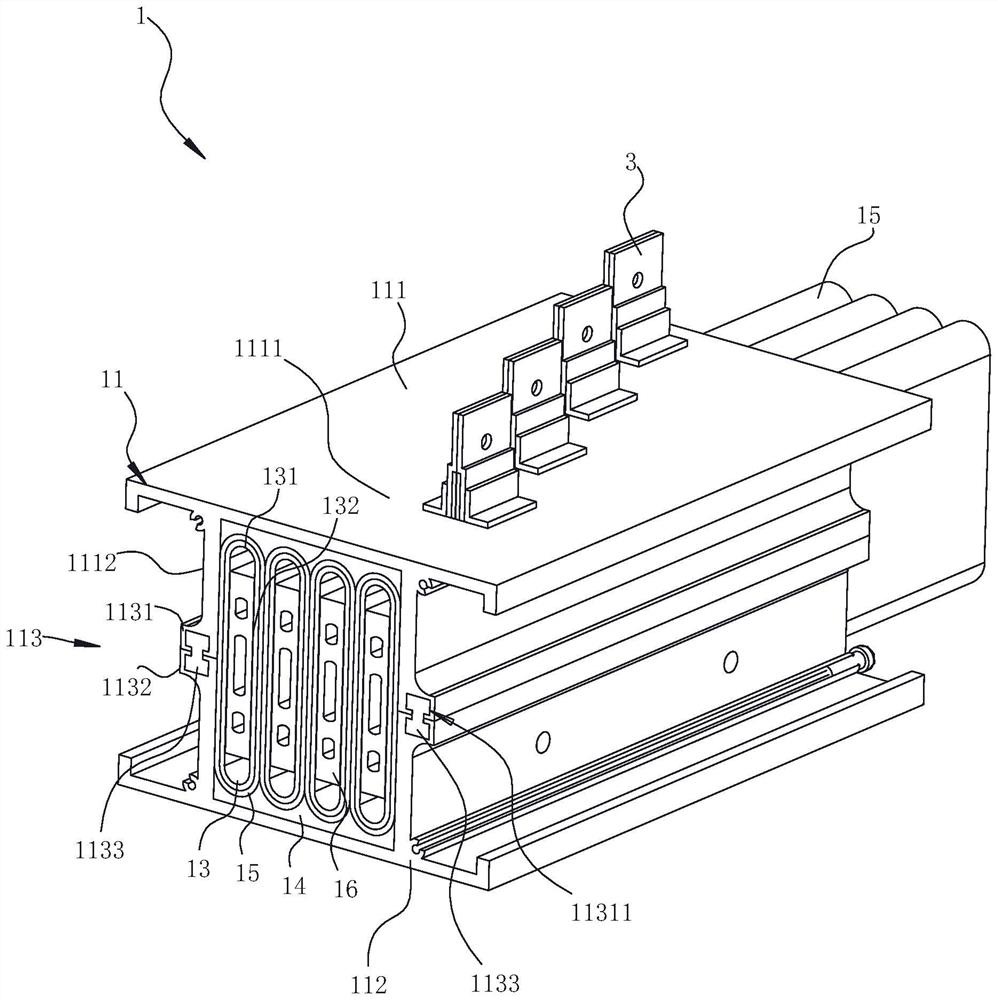

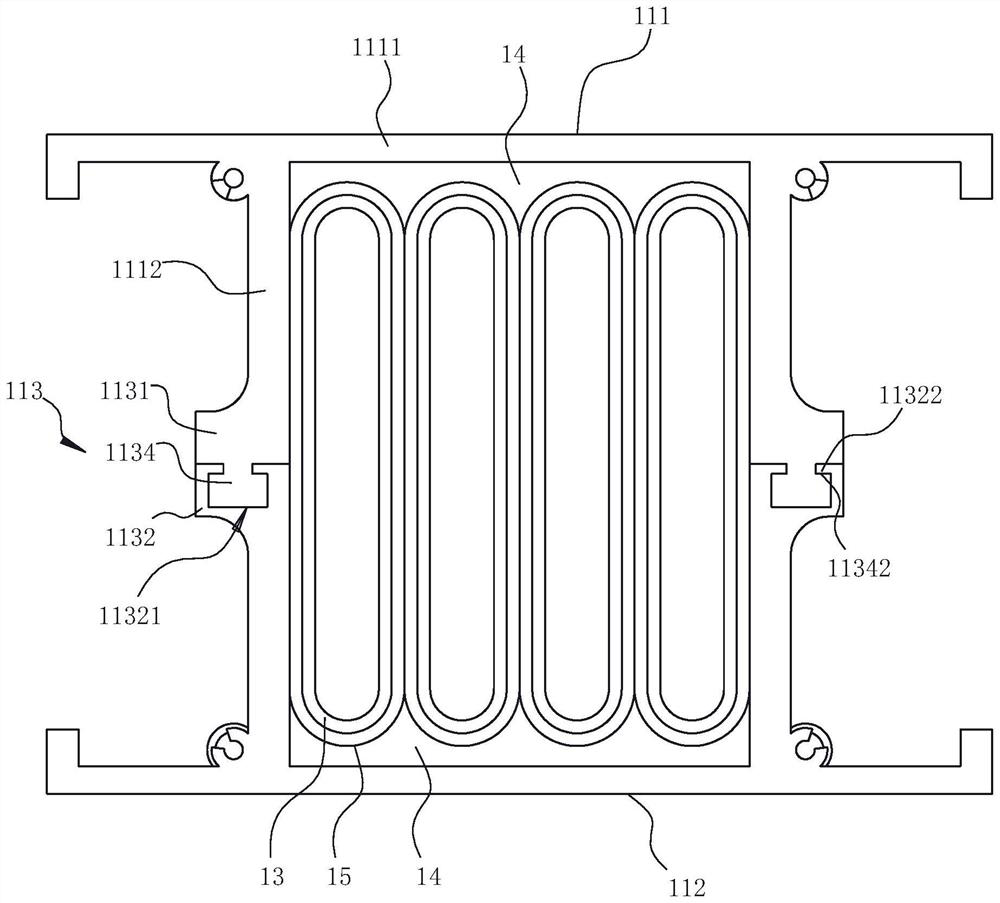

[0055] refer to figure 2 , the busbar 1 includes a shell 11, a conductive busbar and a filler 14, and the conductive busbar includes a plurality of tubular conductors 13 arranged in parallel. The housing 11 is an assembled housing 11, and the housing 11 includes two half-shells, namely a first half-shell 111 and a second half-shell 112, and the first half-shell 111 and the second half-shell 112 are through a lo...

Embodiment 2

[0071] A production process for a bus duct includes: first, selecting a copper plate and bending it into a tubular shape, welding both sides of the copper plate to make a tubular conductor 13; then extruding the tubular conductor 13 to form a flat tubular conductor 13, and then placing the tubular conductor 13 on the tubular conductor 13 is punched, an insulating film 15 is wound around the outer peripheral wall of the tubular conductor 13, and then the busbar is assembled. During assembly, the filler 14 is first laid on the inner surface of the bottom plate 1111 of the first half-shell 111 , and then a plurality of tubular conductors 13 wound with insulating films 15 are placed side by side in the first half-shell 111 . Another filling piece 14 is laid at the outer end of the second half-shell 112 , and then the second half-shell 112 is locked and connected with the first half-shell 111 .

[0072] The locking connection between the second half-shell 112 and the first half-she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com