Turbine blade profile parameter normal comb-shaped display and interactive application method

A technology of turbine blade and display method, applied in geometric CAD, calculation, hydroelectric power generation, etc., can solve the problem of large difference in the curvature of aero-engine blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the implementation purpose, technical solutions and advantages of the present application clearer, the technical solutions in the embodiments of the present application will be described in more detail below with reference to the accompanying drawings in the embodiments of the present application.

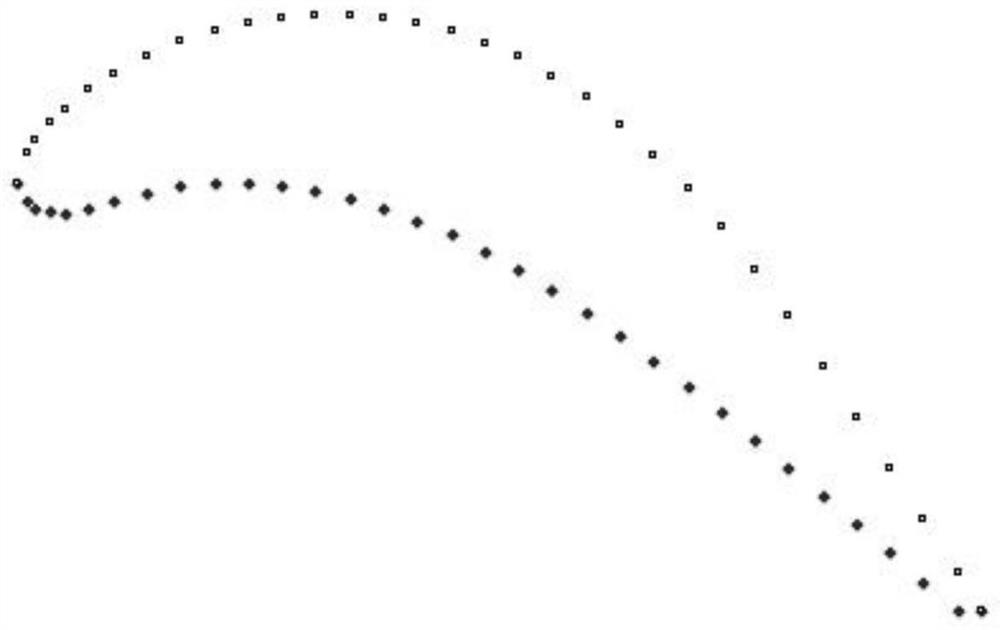

[0028] A normal comb display method for turbine blade profile parameters, such as figure 1 shown, including the following steps:

[0029] like figure 2 As shown in step S100, the discrete points of the blade profile are selected and read in, and the discrete points are fitted into the blade profile by the cubic spline method, and the sequence of the discrete points is judged;

[0030] By using the parametric cubic spline method to fit the discrete points of the airfoil, the second-order continuity can be guaranteed at the node position, and the smooth continuity at the node is ensured. Curves in sharp locations produce singularities, self-intersections, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com