Bicrystal ultrasonic probe and automatic sensitivity detection method of flaw detection system thereof

An automatic detection and ultrasonic technology, which is applied in the use of sound waves/ultrasonic waves/infrasonic waves for material analysis, measuring devices, and greenhouse gas reduction. It can solve problems such as long detection time and difficult use, and achieve efficient probe self-inspection and save time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

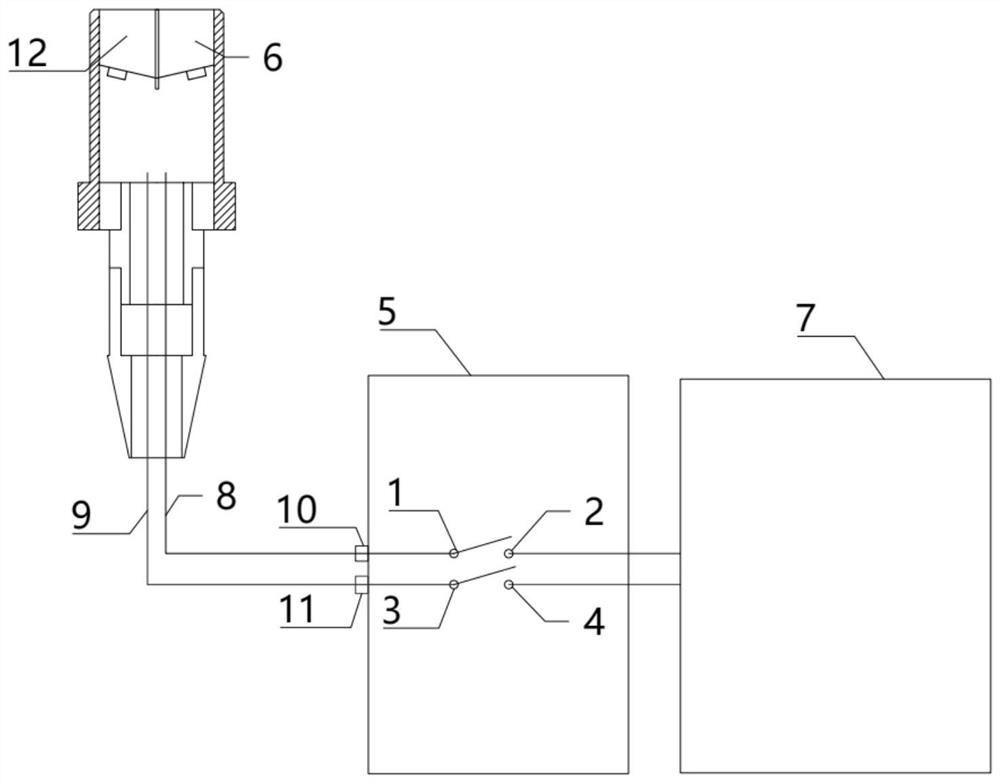

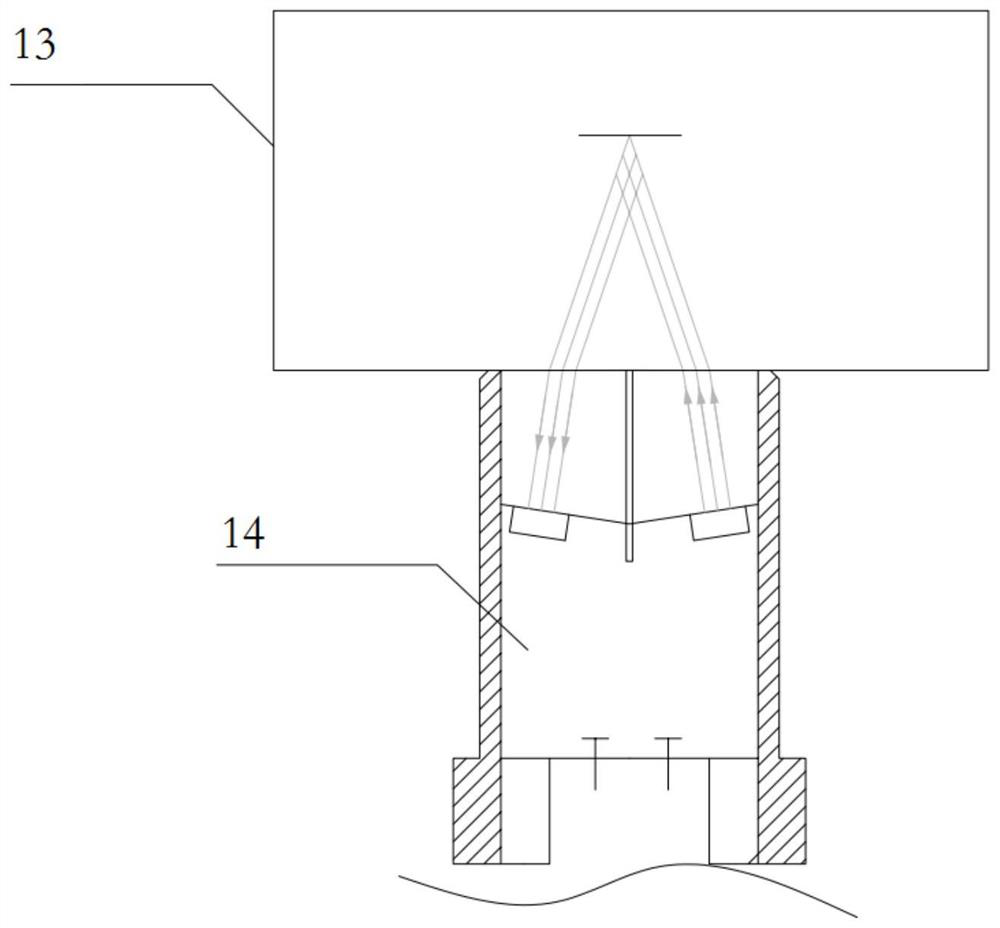

[0037] The working process of the sensitivity automatic detection method of the dual crystal ultrasonic probe and the flaw detection system of the present embodiment is as follows: Image 6 shown:

[0038] Step 1: Utilize artificial standard defects of standard test blocks (such as Flat-bottomed hole, the specific defect depends on the flaw detection standard), test the sensitivity of the dual-crystal ultrasonic probe and its flaw detection system, record the sensitivity amplitude (wave height amplitude) at this time as H1 (set as the reference value), record the current Probe gain value S1 (set as reference value).

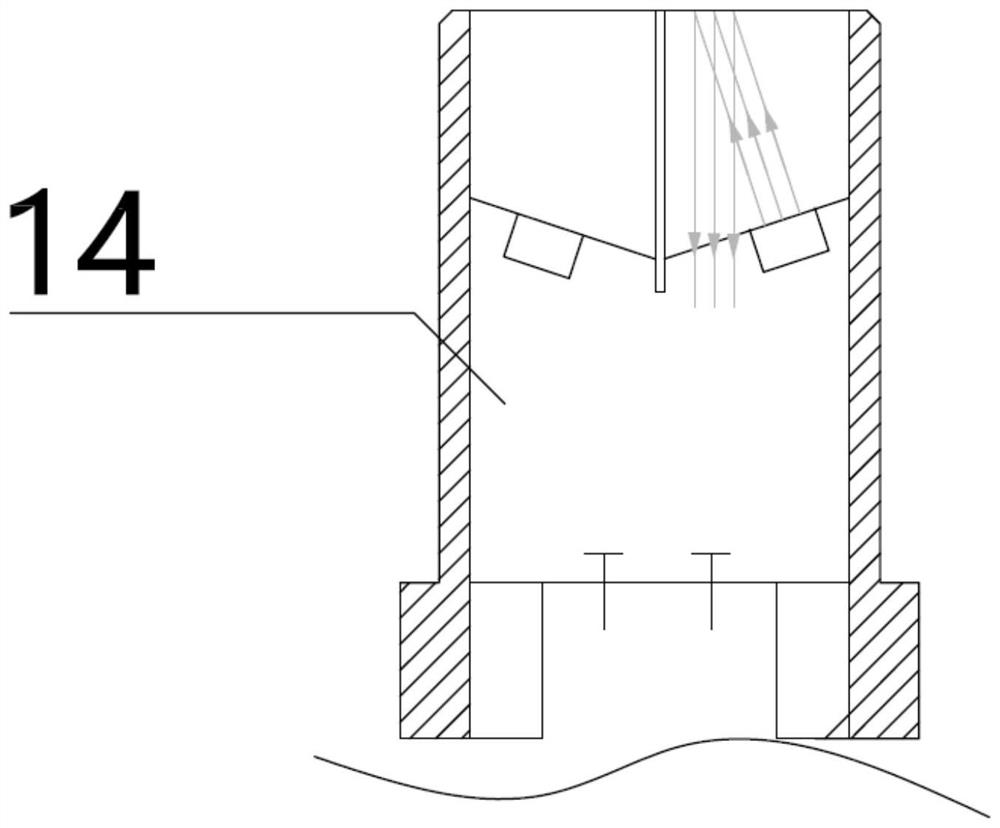

[0039] Step 2: Use the emitter 6 of the dual-crystal ultrasonic probe 14 to transmit ultrasonic waves (the echo line of the echo pole 12 is disconnected at this time). Due to the existence of the organic glass of the emitter 6 itself, an interface wave (such as image 3 shown), the emitter 6 receives the interface wave through a special circuit, at this time t...

Embodiment 2

[0050] using as Figure 5 The shown emitter and echo pole are connected in parallel to form a transmit echo pole, and a method for automatic detection of the sensitivity of the dual-crystal ultrasonic probe and its flaw detection system is performed.

[0051] Step 1: Utilize artificial standard defects of standard test blocks (such as Flat-bottomed hole, the specific defect depends on the flaw detection standard), test the sensitivity of the dual-crystal ultrasonic probe and its flaw detection system, record the sensitivity amplitude (wave height amplitude) at this time as H1 (set as the reference value), record the current Probe gain value S1 (set as reference value).

[0052] Step 2: Use the transmitting echo pole of the dual-crystal ultrasonic probe 14 to transmit ultrasonic waves. Due to the existence of the organic glass of the transmitting echo pole itself, an interface wave (such as Figure 5 shown), the transmitting echo pole receives the interface wave through a sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com