Plastic fiber liner assembly and electric water heater

A technology for electric water heaters and tanks, applied in water heaters, fluid heaters, solar thermal power generation, etc., can solve the problems of low space utilization, occupied space, and large overall thickness, and achieve improved space utilization and thickness The effect of reducing and increasing intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

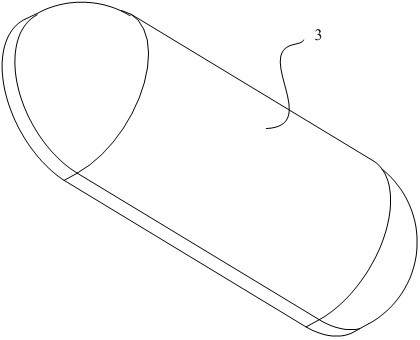

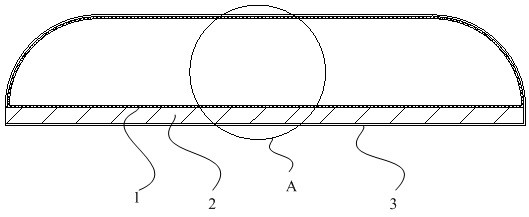

[0035] Example one, as Figure 1-Figure 3 shown, plastic fiber liner components, including:

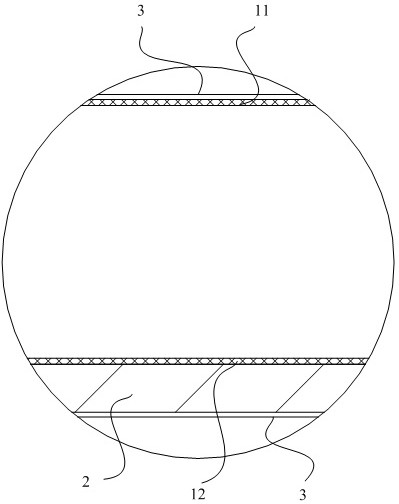

[0036] The plastic liner 1 has a flat structure as a whole; the plastic liner 1 has an arc surface 11 and a flat surface 12, the edge of the arc surface 11 is connected with the edge of the flat surface 12, and water storage is formed between the arc surface 11 and the flat surface 12. cavity;

[0037] Reinforcing plate 2, the reinforcing plate 2 abuts on the plane part 12;

[0038] In the filament winding layer 3 , the fibers are wound around the arc surface portion 11 and the outside of the reinforcing plate 2 to form the filament winding layer 3 .

[0039] Specifically, the plastic inner container 1 used in the plastic fiber inner container assembly of this embodiment adopts a flat structure, the front surface adopts an arc surface portion 11 with an arc-shaped cross-section, and the back surface adopts a flat surface portion 12 with a flat plate structure. For the structural st...

Embodiment 2

[0045] Example two, as Figure 4-Figure 8 As shown, the present invention also provides an electric water heater, comprising: an outer shell and a plastic fiber inner pot assembly, wherein the plastic fiber inner pot assembly is built in the outer shell, so as to protect the plastic fiber inner pot assembly by the outer shell,

[0046] The structural form of the outer shell matches that of the plastic fiber liner component, and the plastic fiber liner component is a flat structure. Correspondingly, the outer shell is also designed to be a flat structure to match the installation of the inner liner.

[0047] In some embodiments, since the inner container of the plastic fiber inner container assembly has an arc surface portion 11, correspondingly, the outer shell is also formed with a corresponding arc surface structure. In order to meet the assembly requirements of the arc surface shell and improve the appearance effect, the shell includes a first shell 100 , a second shell 200...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com