HRB400E ordinary-speed hot-rolled ribbed steel bar with tensile strength of 700 Mpa or above

A hot-rolled ribbed steel bar, tensile strength technology, applied in the direction of metal rolling, temperature control, etc., can solve the problems of low tensile strength, low strength-to-yield ratio, etc., and achieve the effect of excellent seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

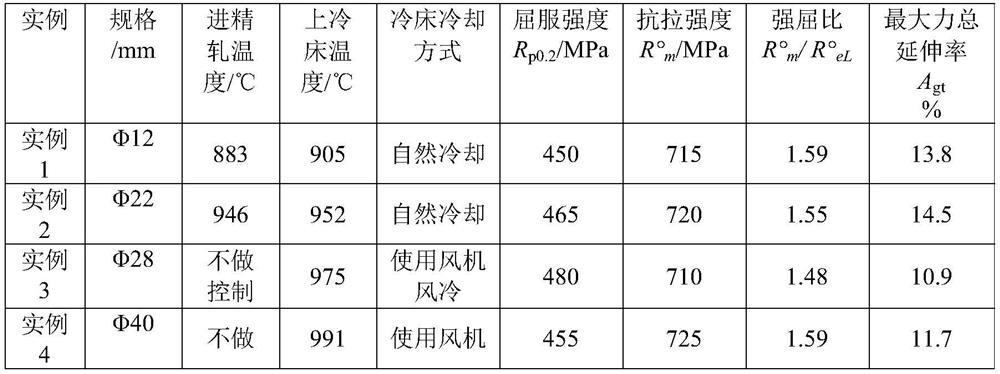

[0021] In order to have a clearer understanding of the technical features, objects and effects of the present invention, the present invention will now be described.

[0022] This application is suitable for ordinary bars, and the finish rolling speed is relatively slow. According to different specifications, the finish rolling speed (the exit speed of the finishing mill in hot tandem rolling) is only 1 / 3 to 1 / 2 of that of high-speed bars. At the same time, due to different production lines, more alloys need to be added to achieve the same performance, and more specifications are produced than high-speed bars.

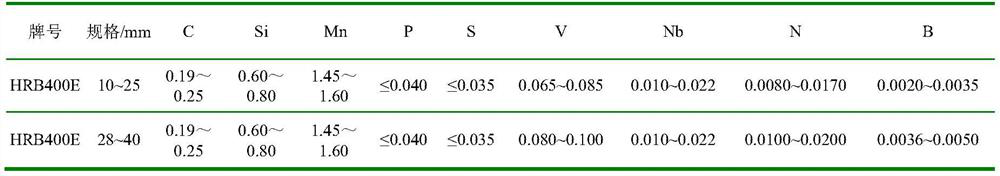

[0023] (1) Composition design: increase the content of Si and Mn in the steel and add V element to combine with N in the steel to increase the strength, control the N element in the steel within a reasonable range, so that most of the N is combined with V to reduce the free N in the steel . When B element is added, since most of N in steel combines with V to produce c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| strength to yield ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com