Transferring and stacking equipment for bagged flour production and using method thereof

A technology for stacking equipment and flour, applied in biological packaging, object stacking, transportation and packaging, etc., can solve problems such as poor flexibility, increased human labor, and reduced equipment reliability, so as to increase the speed of clamping and reduce manpower Labor, the effect of improving the efficiency of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make it easy to understand the technical means, creation features, achieved goals and effects of the present invention, the present invention will be further described below with reference to the specific embodiments.

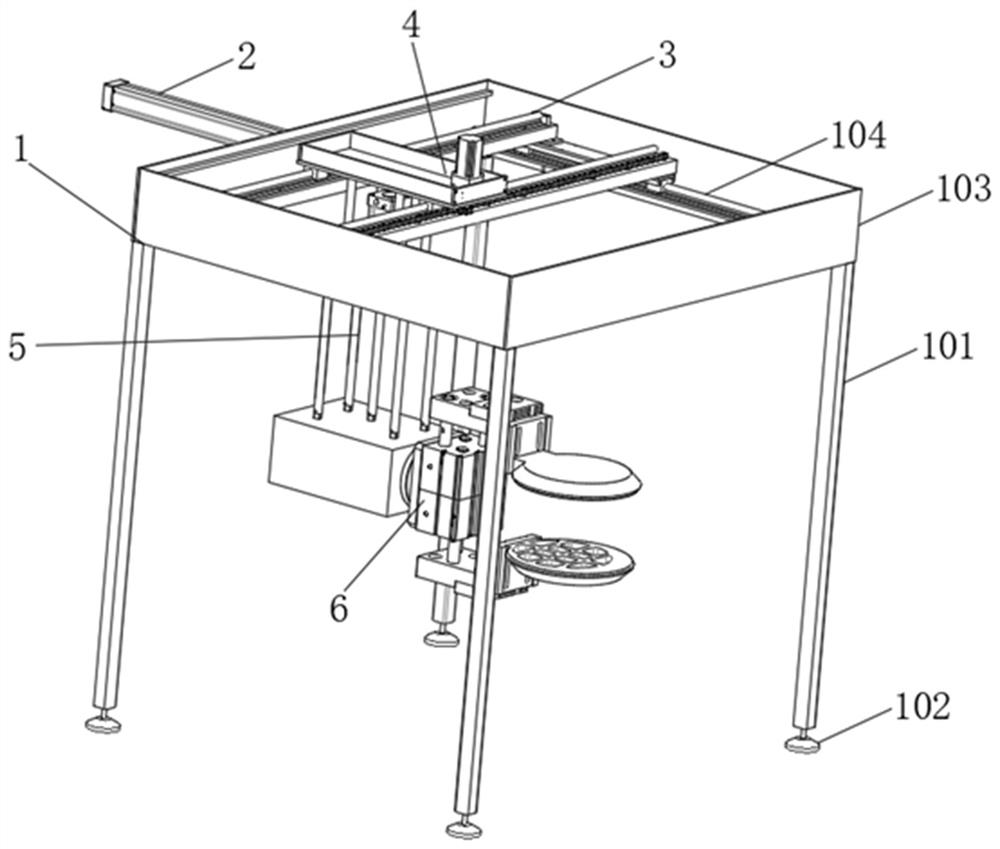

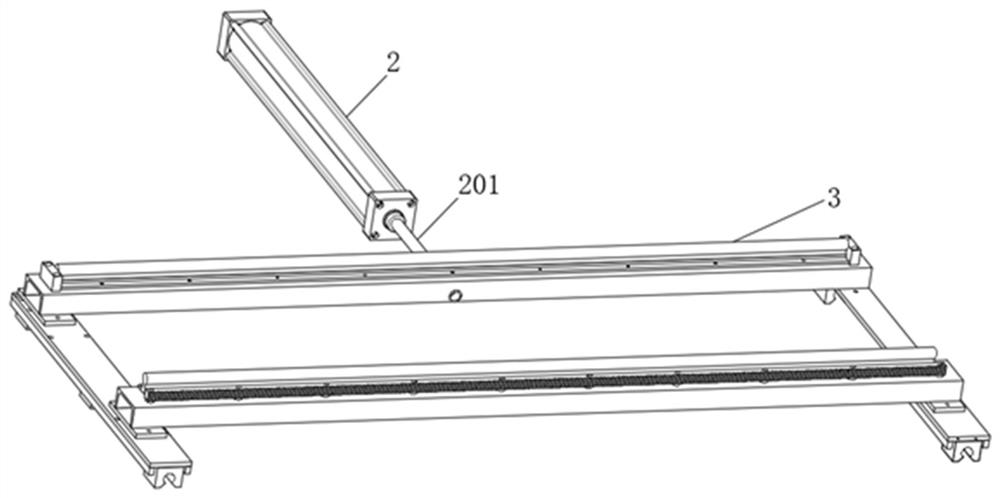

[0039] like Figure 1-Figure 8 As shown, a transfer stacking device for bagged flour production according to the present invention includes a support frame 1, a mobile bottom frame 3, a moving assembly 4, a lifting assembly 5 and a clamping assembly 6. The top of the support frame 1 is slidably fitted with a The mobile chassis 3, the top of the mobile chassis 3 is slidably fitted with a mobile component 4, the bottom of the mobile component 4 is connected with a lifting component 5, and the bottom of the lifting component 5 is fixedly connected with a clamping component 6;

[0040] The support frame 1 includes a support column 101, a frame 103 and a first slide rail 104. The four support columns 101 are arranged vertically. The tops of the fo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap