Reciprocating motion mechanism

A technology of reciprocating motion mechanism and driving wheel, which is used in conveyor objects, transportation and packaging, furnaces, etc., can solve problems such as being vulnerable to impact, and achieve the effects of small impact force, stable extension and contraction rate, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

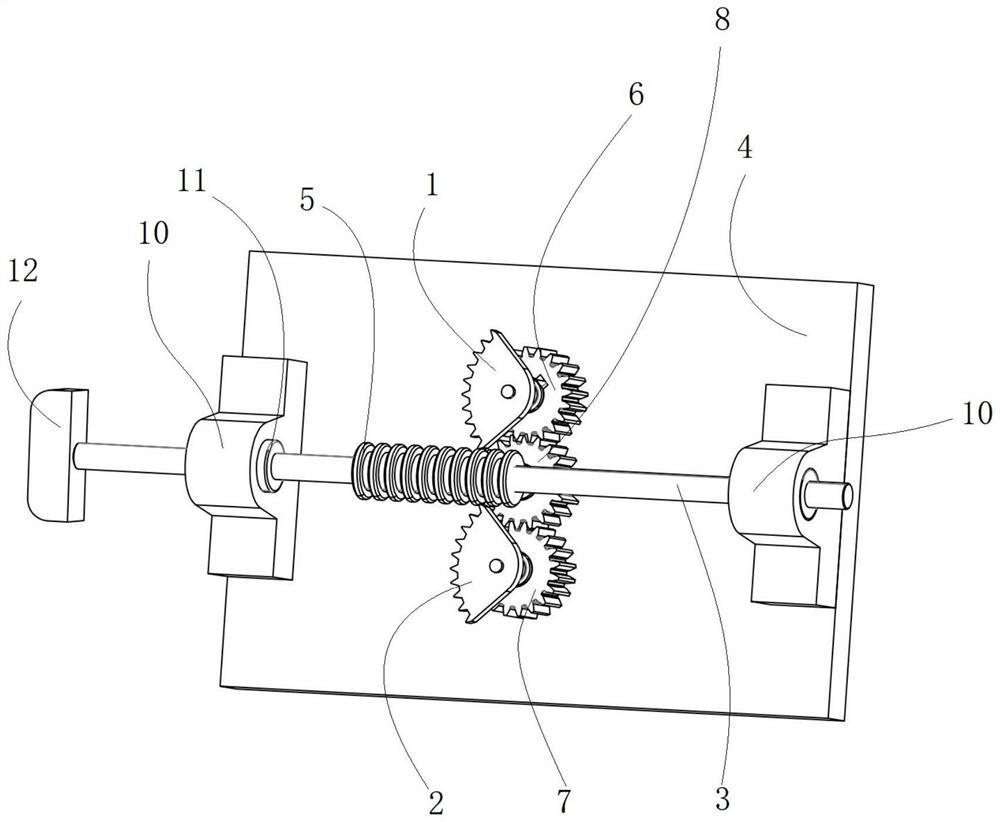

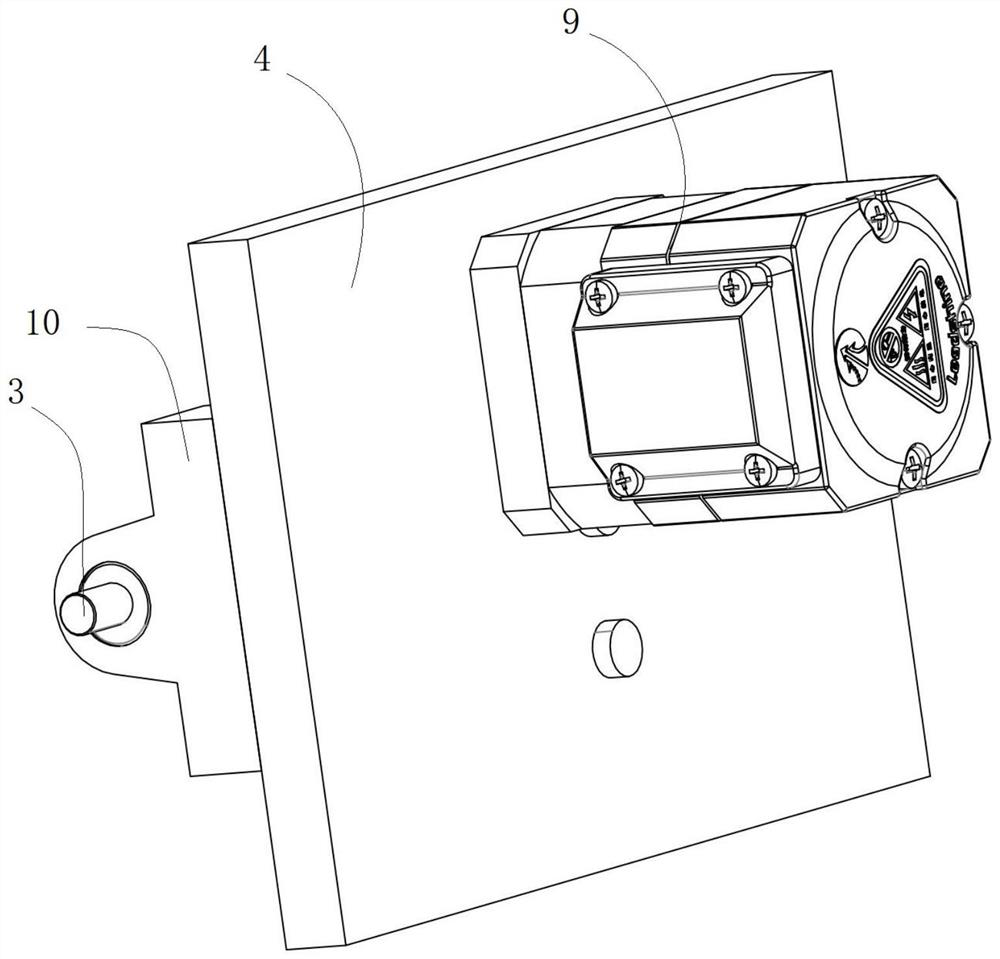

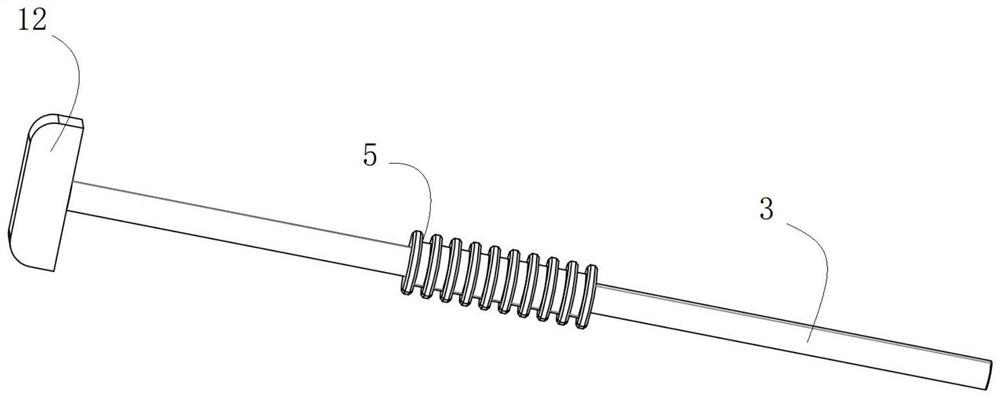

[0025] figure 1 As shown, the reciprocating mechanism includes a first sector tooth 1, a second sector tooth 2, a telescopic rod 3, the first sector tooth 1 and the second sector tooth 2 are arranged at intervals, and the telescopic rod 3 is arranged on the first sector tooth 1 and the second sector tooth 2. Between the two sector teeth 2, the rod body of the telescopic rod 3 is provided with a meshing part along the length direction of the telescopic rod 3, the rotation directions of the first sector tooth 1 and the second sector tooth 2 are the same, It is used to alternately engage with the meshing parts on the telescopic rod 3 to drive the telescopic rod 3 to reciprocate, and the telescopic rod 3 is driven to move horizontally by the rotation of the sector teeth, and the first fan teeth 1 and the second fan teeth 2 cooperate to realize the telescopic rod. 3 Linear and uniform reciprocating motion to avoid impact on the material when pushing the material.

[0026] Specific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com