Mounting structure for spindle unit of numerical control machine tool

A technology of installation structure and CNC machine tools, which is applied in the direction of metal processing equipment, etc., can solve problems such as assembly errors, low assembly efficiency, and easily limited operating space, and achieve the effect of increasing the force-bearing area and maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creation features, achievement goals and effects realized by the present invention easy to understand, the present invention will be further described below in conjunction with the specific embodiments.

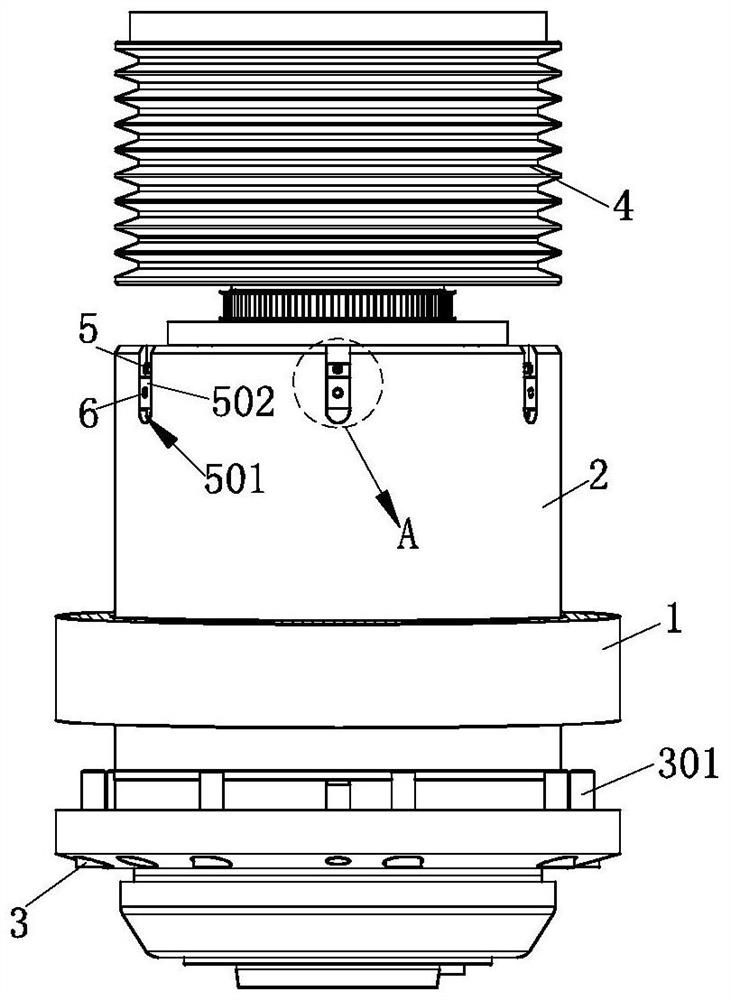

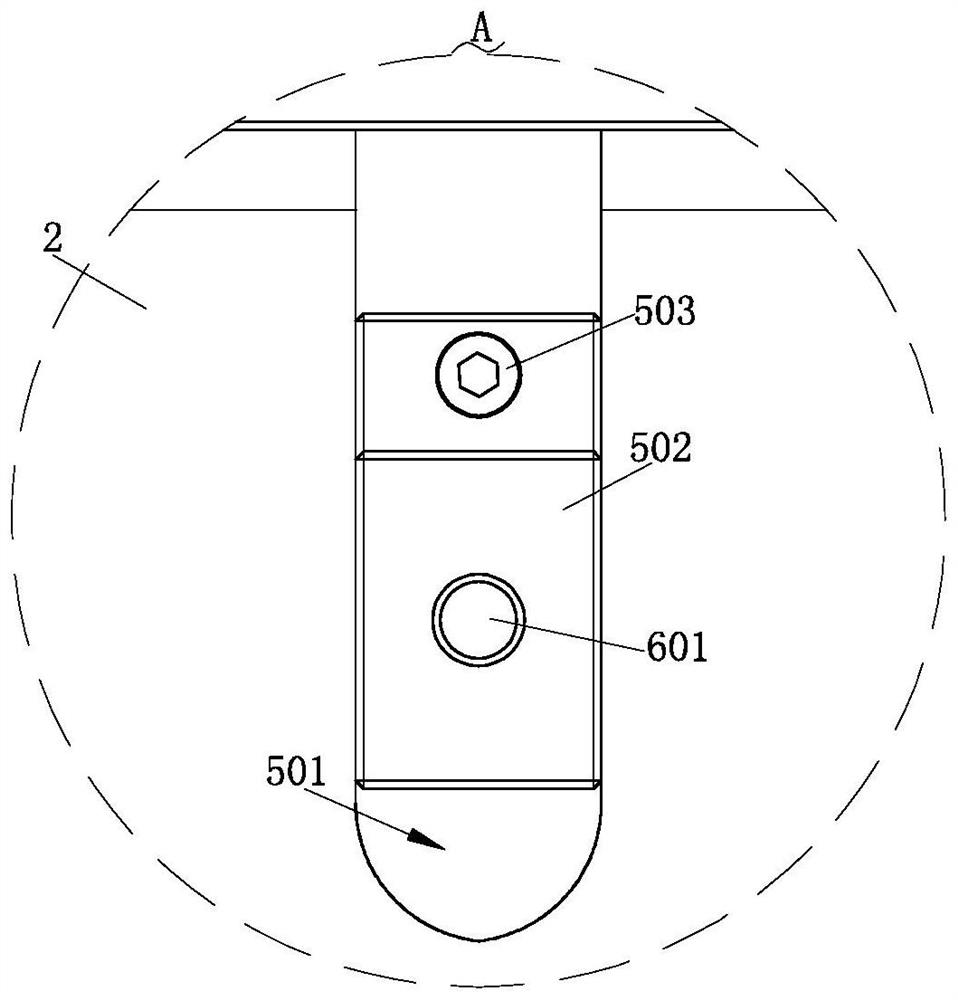

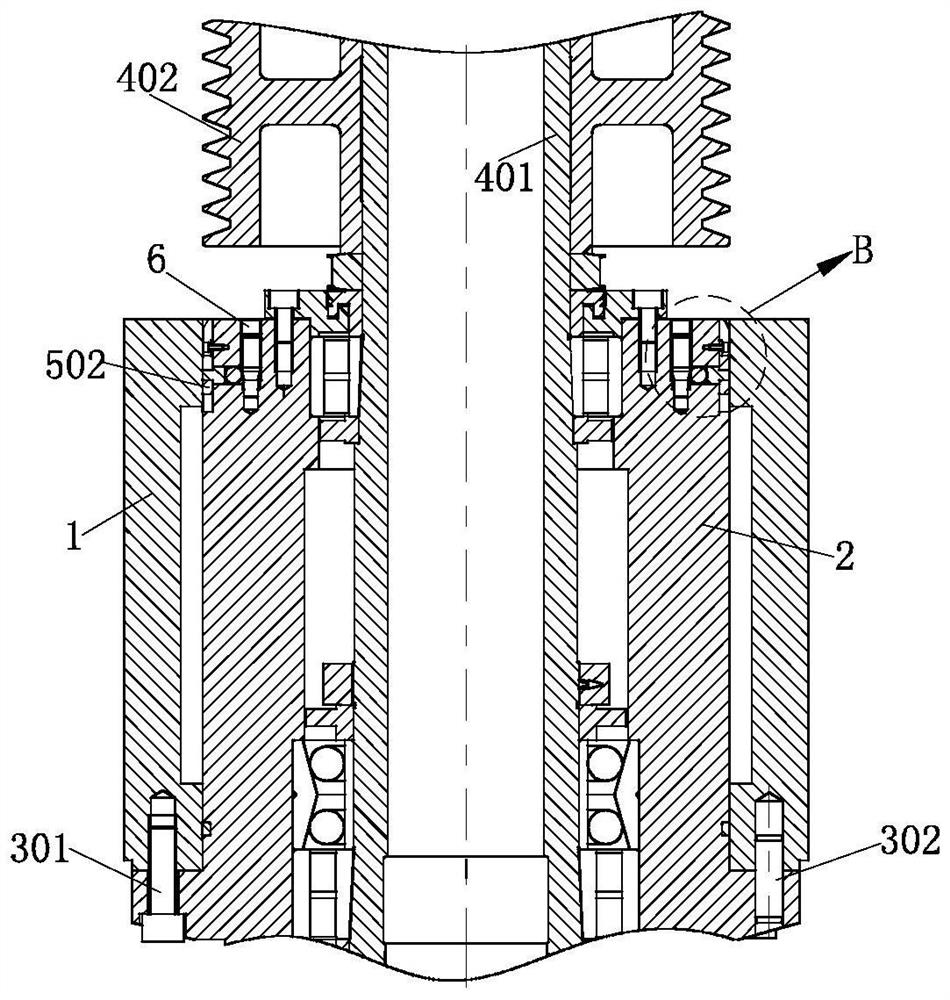

[0023] like Figure 1-Figure 4 As shown, the installation structure of a CNC machine tool spindle unit according to the present invention includes a spindle box 1, and the inside of the spindle box 1 is fixedly connected with a spindle sleeve 2 through a first fixing mechanism 3. A plurality of groups of connection mechanisms 5 are provided at equal distances on the outside, the top of the main shaft sleeve 2 is provided with a plurality of second fixing mechanisms 6 corresponding to the connection mechanisms 5, and the interior of the main shaft sleeve 2 is provided with a power mechanism 4;

[0024] The first fixing mechanism 3 includes a hexagon socket head screw 301 and a cylindrical pin 302, and the spindle sleeve 2 and the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com