Modified molecular sieve for CO2 adsorption separation and preparation method and device thereof

An adsorption separation and molecular sieve technology, which is applied in the field of carbon capture, can solve the problems of a large amount of waste liquid and the decrease of adsorption capacity, and achieve the effect of high efficiency load, increase adsorption capacity, and increase chemical adsorption force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] one for CO 2 The preparation method of the modified molecular sieve separated by adsorption comprises the following steps:

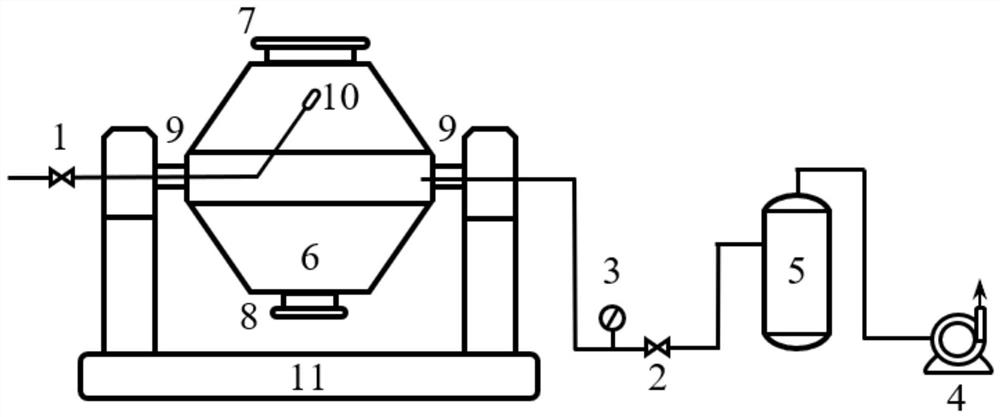

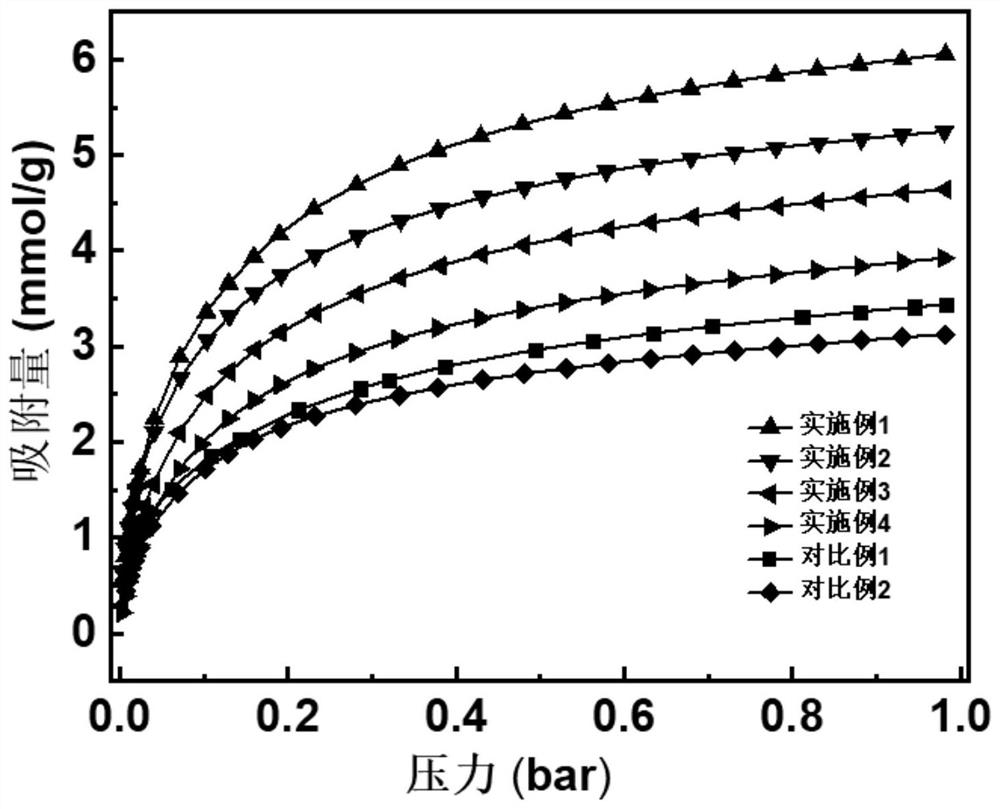

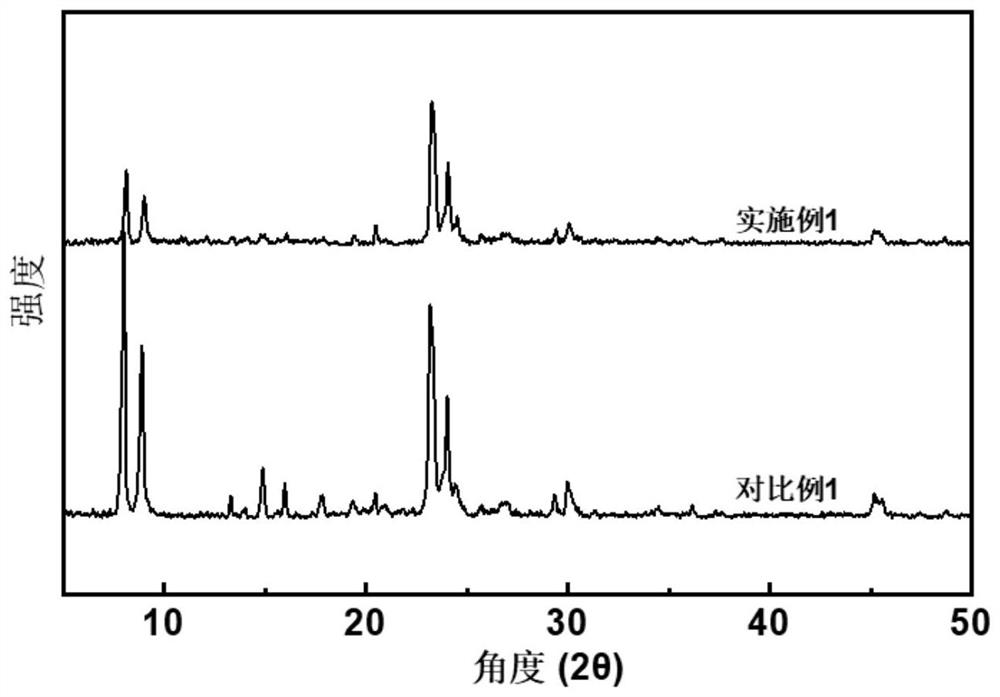

[0037] After weighing the MEL molecular sieve of 100kg and putting it into the double-cone vacuum heating tank 6, the feed port 7 is closed, the second valve 1 is opened, and the vacuum tightness is controlled to be-0.1MPa by the vacuum pump 4, and the product A is obtained at 200 ℃ of degassing and activation for 6 hours; The vacuum degree is controlled by the vacuum pump 4 to be -0.06MPa. After the equipment is stabilized, the first valve 1 is opened and 2kg of triethylamine is injected into the double-cone vacuum heating tank 6 through the nozzle 10. After entering the double-cone vacuum heating tank 6, the first valve 1 is closed, and the double cone vacuum heating tank 6 is closed. The cone vacuum heating tank 6 is kept at 200°C, and the rotational speed is 15RPM. After 20min, 10kg triethylamine is injected into the double cone vacuum heating...

Embodiment 2

[0039] one for CO 2 The preparation method of modified molecular sieve for adsorption separation comprises the following steps:

[0040] After weighing the MEL molecular sieve of 100kg and putting it into the double-cone vacuum heating tank 6, the feed port 7 is closed, the second valve 1 is opened, and the vacuum tightness is controlled to be-0.08MPa by the vacuum pump 4, and the product A is obtained at 200 ℃ of degassing and activation for 2 hours; The vacuum degree controlled by the vacuum pump 4 is -0.06MPa. After the equipment is stable, the first valve 1 is opened and 3kg of triisopropanolamine is injected into the double-cone vacuum heating tank 6 through the nozzle 10. After entering the double-cone vacuum heating tank 6, the first valve 1 is closed, Open the double-cone vacuum heating tank 6 to keep 150 ℃, and the rotation speed is 10RPM, after 20min, inject 9kg triisopropanolamine into the double-cone vacuum heating tank 6 again, the rotation speed is changed to 20R...

Embodiment 3

[0042] one for CO 2 The preparation method of modified molecular sieve for adsorption separation comprises the following steps:

[0043] After weighing the MEL molecular sieve of 100kg and putting it into the double-cone vacuum heating tank 6, the feed port 7 is closed, the second valve 1 is opened, and the vacuum degree is controlled to be-0.1MPa by the vacuum pump 4, and the product A is obtained at 180 ° C of degassing and activation for 4 hours; The vacuum degree is controlled to be -0.08MPa by the vacuum pump 4. After the equipment is stable, the first valve 1 is opened and 4kg of methyldiethanolamine is injected into the double-cone vacuum heating tank 6 through the nozzle 10. After entering the double-cone vacuum heating tank 6, the first valve 1 is closed, and the open The double-cone vacuum heating tank 6 is kept at 250°C, and the rotation speed is 20RPM. After 20min, 8kg methyldiethanolamine is injected into the double-cone vacuum heating tank 6 again, and the rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com