Testing device and method suitable for non-standard multi-element compound fatigue fracture

A fatigue fracture and test device technology, which is applied in the direction of applying repeated force/pulsation force to test the strength of materials, measuring devices, instruments, etc., can solve the problems of increasing test cost, material cost and high processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] In order to make the objectives, technical solutions and advantages of the present invention clearer, the technical solutions of the present invention will be clearly and completely described below with reference to the specific embodiments of the present invention and the corresponding drawings. The technical solutions provided by the examples of the present invention will be described in detail below with reference to the accompanying drawings.

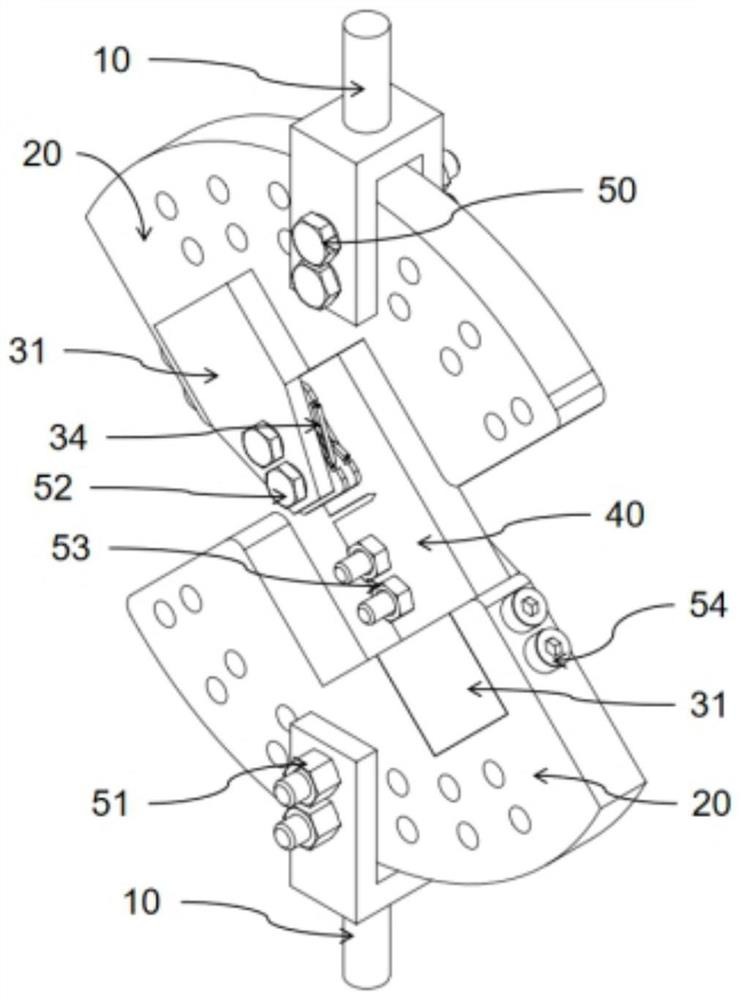

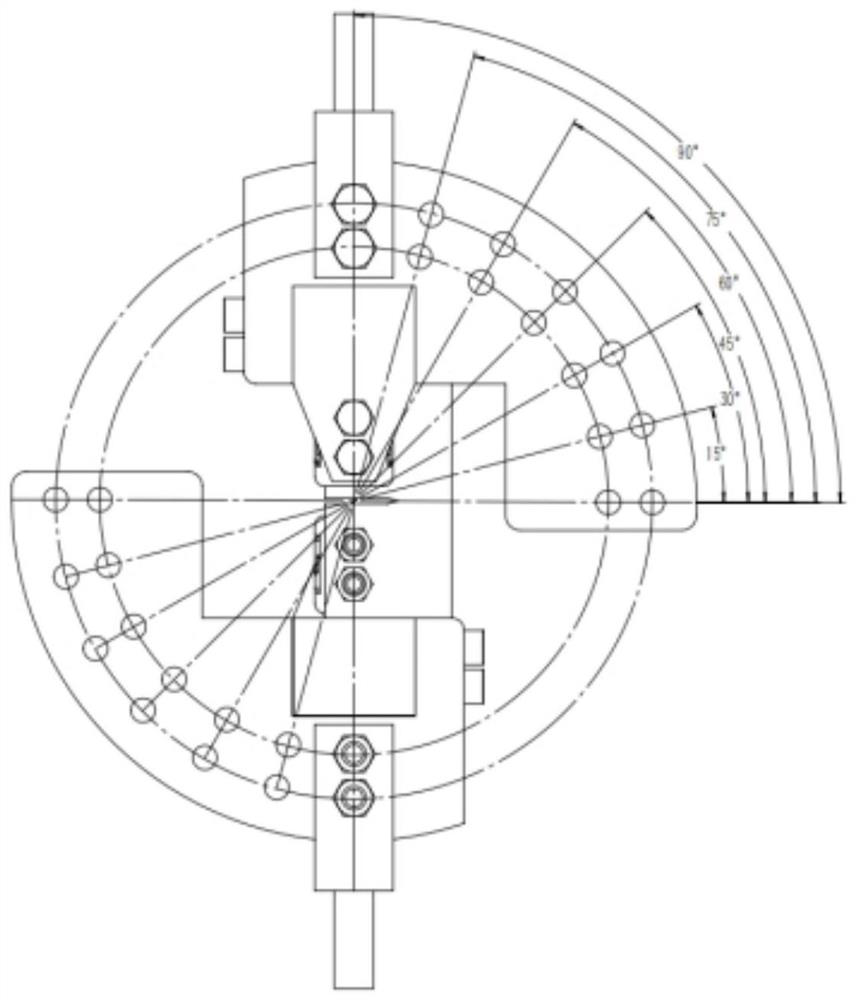

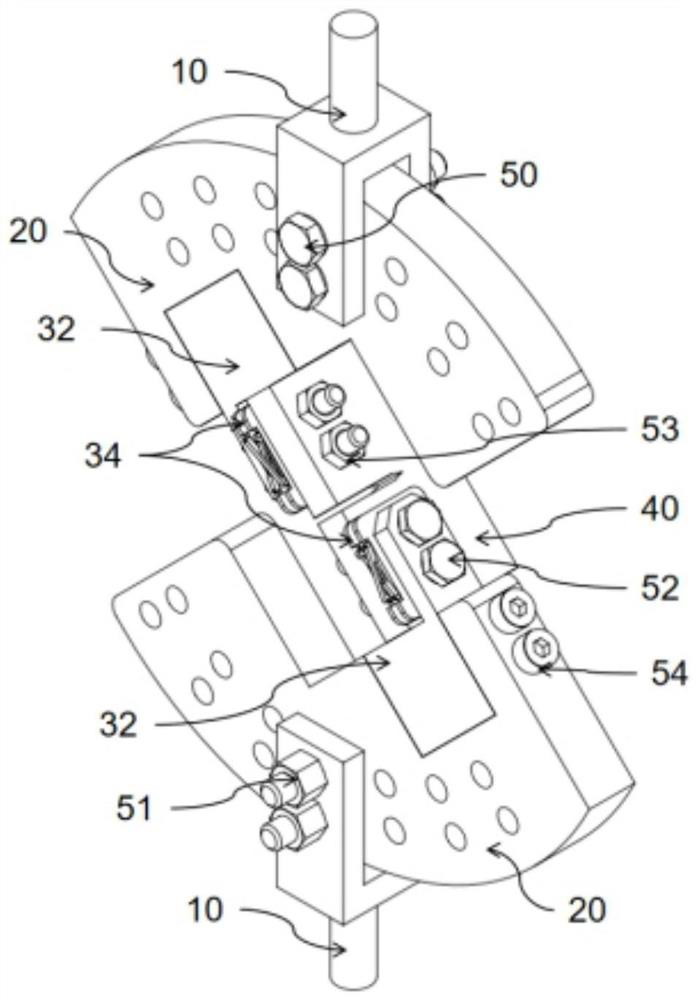

[0057] According to the present invention, a test device and method suitable for non-standard multi-component composite fatigue fracture are provided for testing composite fatigue fracture behavior of materials. Figure 1 shows the situation of I-II composite type loading, which is subjected to tensile and plane shearing during the experiment; Figure 2 is the situation of I-III type loading, which is subjected to tensile and anti-plane shearing during the experiment Figure 3 is a schematic diagram of the structure of type II-I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com