Different-depth sample sampling device for liquid food detection

A liquid food and sampling device technology, applied in the sampling device and other directions, can solve the problems of liquid shaking, mixing, affecting the detection accuracy, etc., and achieve the effect of facilitating rapid drying and accelerating the flow speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

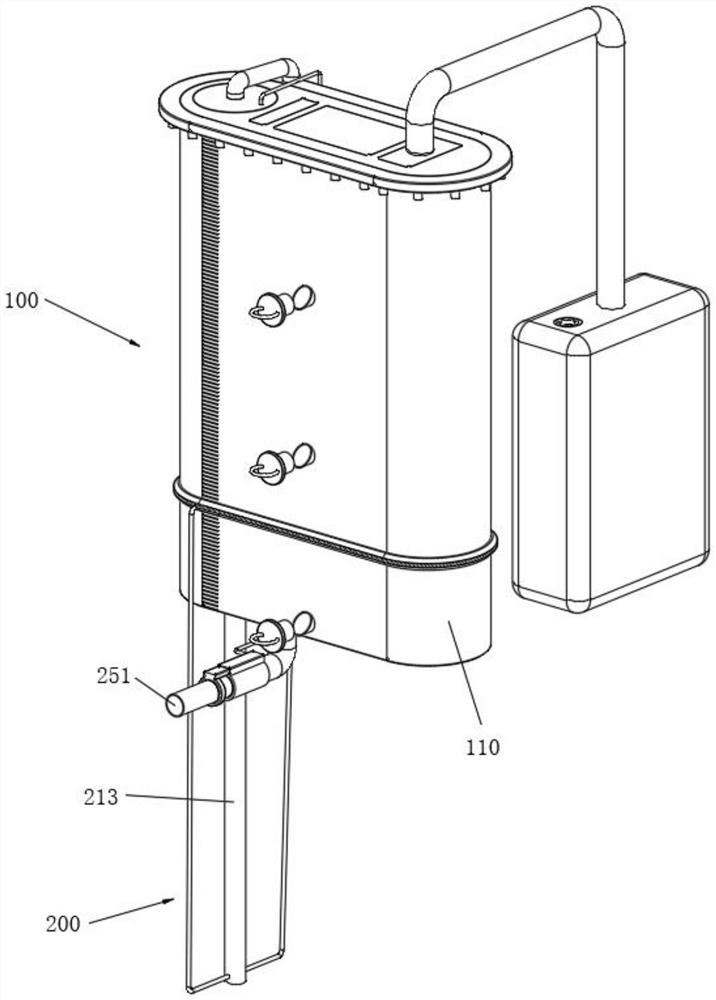

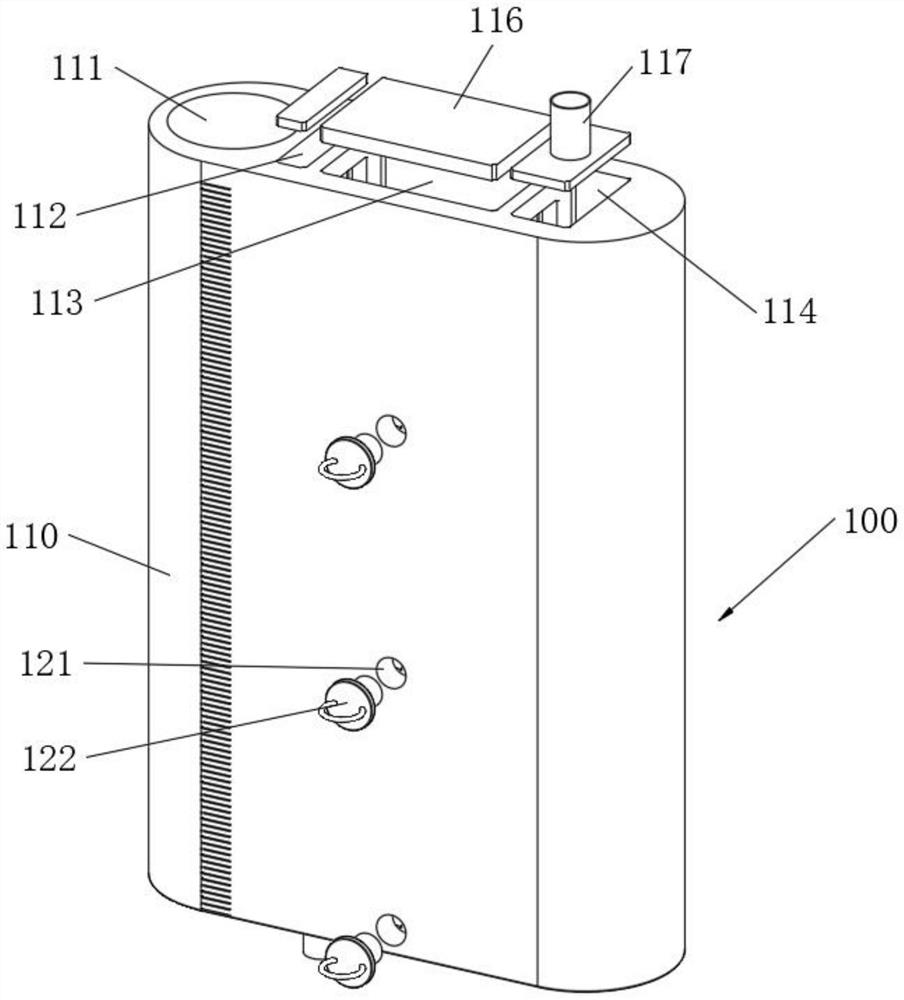

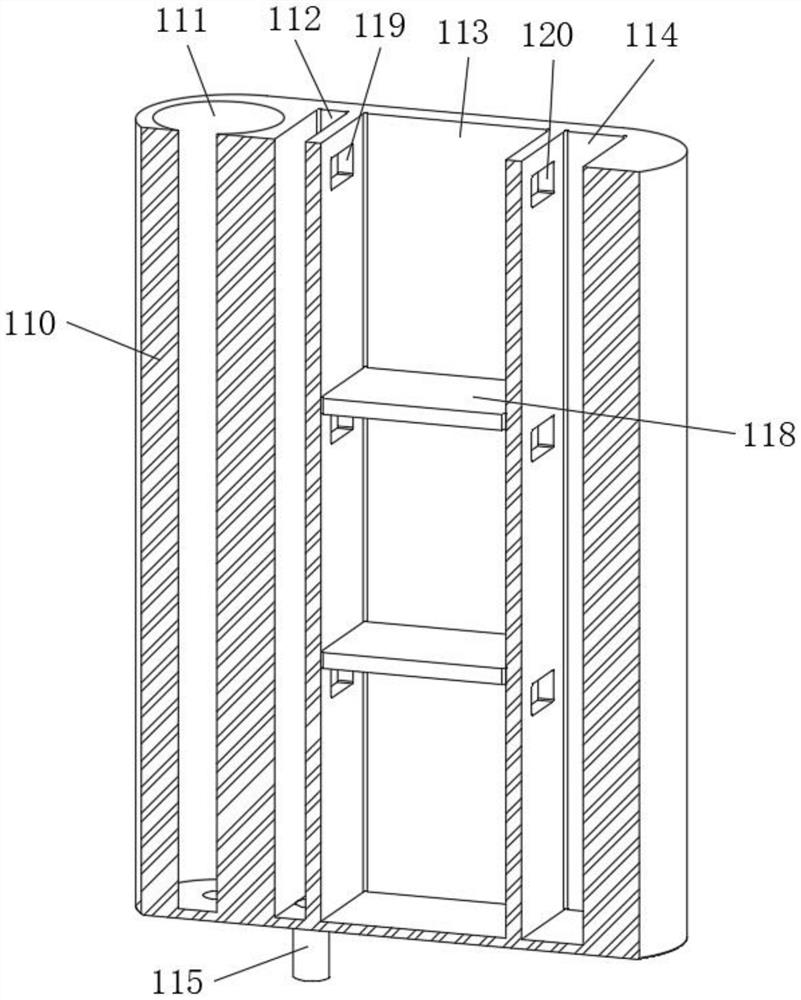

[0051] see Figure 1-Figure 10 As shown, a different depth sample sampling device for liquid food detection is provided, including a liquid storage device 100 and a guide device 200 arranged in the liquid storage device 100. The liquid storage device 100 includes a housing 110, and the housing 110 is arranged in sequence There are a sliding cavity 111, a liquid inlet cavity 112, a liquid storage cavity 113 and a negative pressure cavity 114. The bottom of the casing 110 is provided with a liquid inlet pipe 115 that communicates with the sliding cavity 111. The liquid inlet cavity 112, the liquid storage cavity Both the cavity 113 and the top of the negative pressure cavity 114 are provided with a cover plate 116, wherein the cover plate 116 at the top of the negative pressure cavity 114 is communicated with a through pipe 117, and a plurality of partitions 118 are arranged in the liquid storage cavity 113 to separate the The plate 118 can isolate the liquid storage cavity 113 ...

Embodiment 2

[0061] In order to quickly understand the distance between the shell 110 and the bottom of the container, the following improvements are made on the basis of Example 1:

[0062] see Figure 11-Figure 12 As shown, the side wall of the casing 110 is provided with a scale 230, the outer wall of the bottom end of the connecting rod 213 is provided with a transmission rod 231, and the other end of the transmission rod 231 is connected with an indicator plate 232, and the indicator plate 232 is sleeved on the casing 110. The outer wall, considering that when sampling some opaque liquids, people cannot observe the position of the casing 110 in the liquid. Therefore, when the casing 110 moves down, the casing 110 drives the scale 230 to move down. The distance between the casing 110 and the bottom of the container can be judged according to the position of the indicator plate 232 at the scale 230, so that it is convenient for people to observe the position of the casing 110 in the liq...

Embodiment 3

[0065] In order to facilitate the rapid drying of the outer wall of the housing 110, the following improvements are made on the basis of Example 1:

[0066] see Figure 13 As shown, the top of the sliding cavity 111 is provided with a sealing plate 240, the top of the sealing plate 240 is connected with a mounting pipe 241, the other end of the mounting pipe 241 is connected with a mounting block 242, and the mounting block 242 is sleeved on the top of the housing 110 In the outer wall, the installation block 242 is provided with a gas cavity, and the bottom of the installation block 242 is connected with a plurality of exhaust pipes 243. Considering that when sampling different liquids, the shell 110 needs to be cleaned before sampling. For this reason, When the piston block 211 moves, the gas in the sliding cavity 111 is pushed out, the gas enters the gas cavity in the installation block 242 through the installation pipe 241, and the gas in the gas cavity is discharged to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com