Load control method and system for CFB (Circulating Fluidized Bed) boiler for blending combustion of coal slime

A technology of boiler load and control method, which is applied to the combustion method, the fuel burned in the melted state, the combustion type, etc., can solve the problems of large changes in the amount of slime, unbalanced air distribution, and high labor intensity of operators, so as to solve the problem of load Adjust the lag and solve the effect that cannot be quantified

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

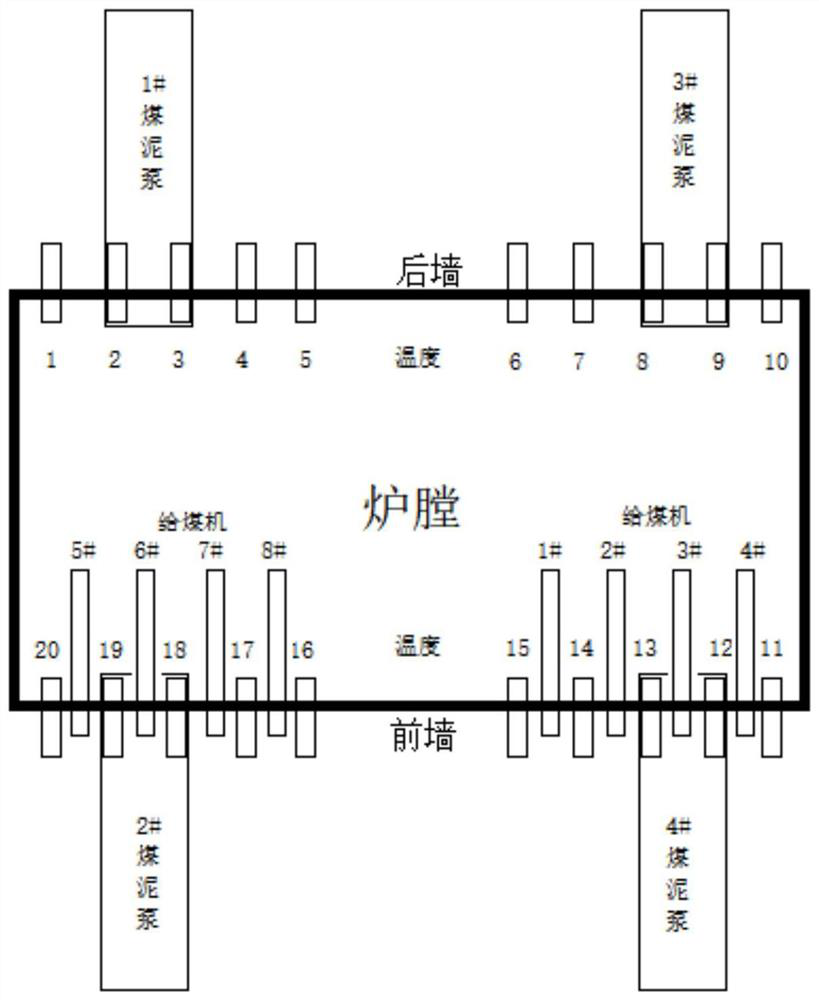

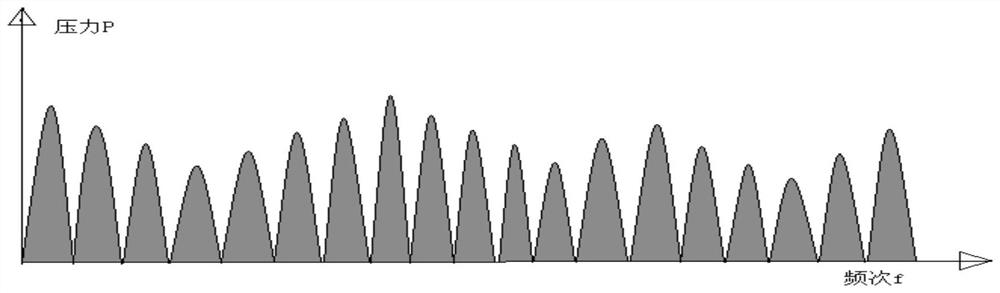

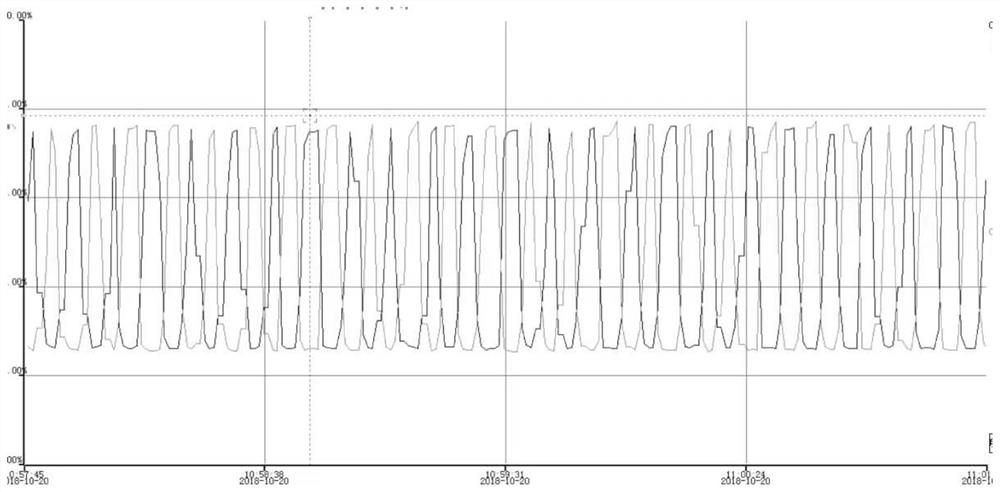

[0055] In order to make the purpose, technical solutions and advantages of the present application more clearly understood, the present application will be described in further detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present application, but not to limit the present application.

[0056] In the description of the present invention, unless otherwise specified, "plurality" means two or more. The terms "first", "second", "third", "fourth", etc. (if any) in the description and claims of the present invention and the above-mentioned drawings are intended to distinguish what is referred to. For a solution with a sequential flow, this term expression does not necessarily describe a specific sequence or sequence, and for a device structure solution, this term expression does not distinguish the importance, positional relationship, or the like.

[0057]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com