Multifunctional press-fitting tool for automobile gearbox accessories

A technology of automotive gearbox and press-fitting tooling, which is applied in the field of assembly tooling, and can solve the problems of inconvenient fixing of automotive gearbox parts, large volume, and inconvenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

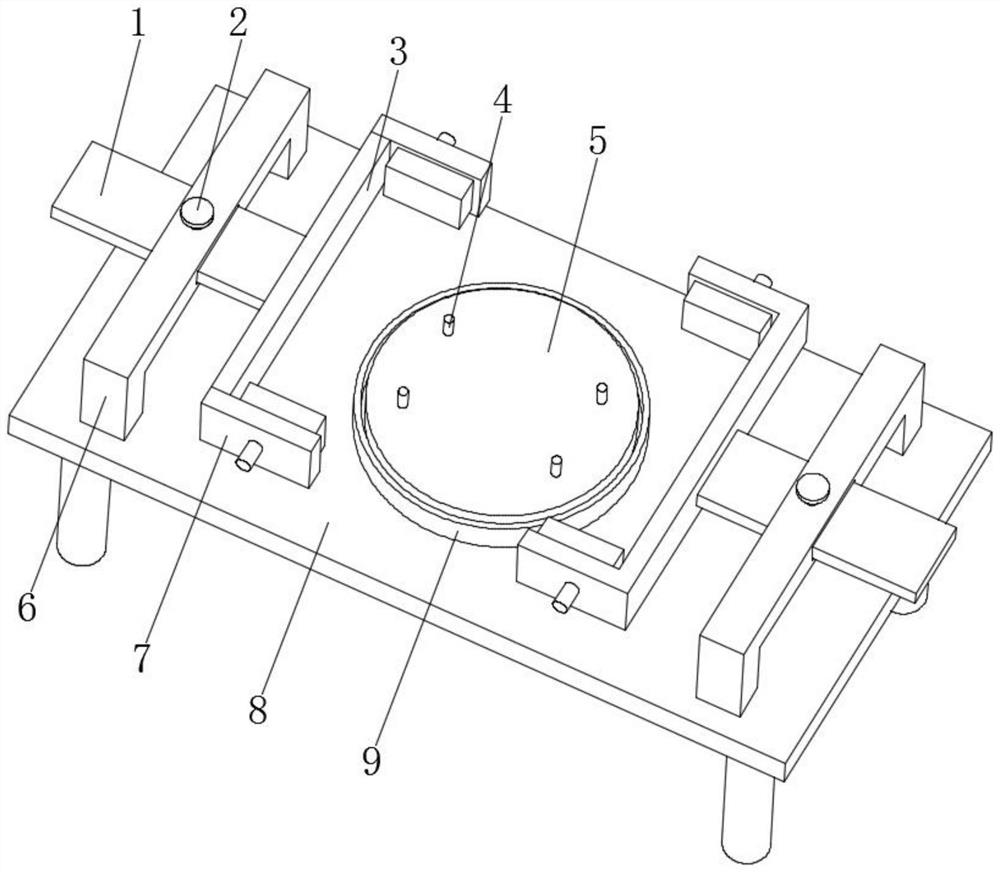

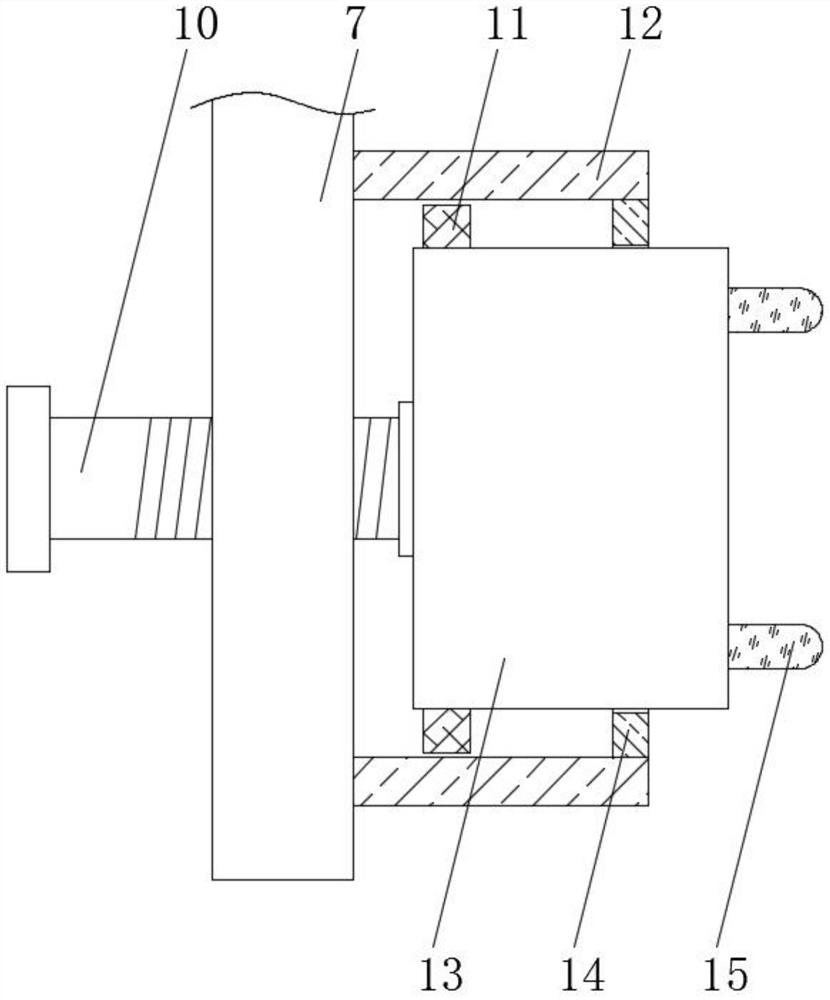

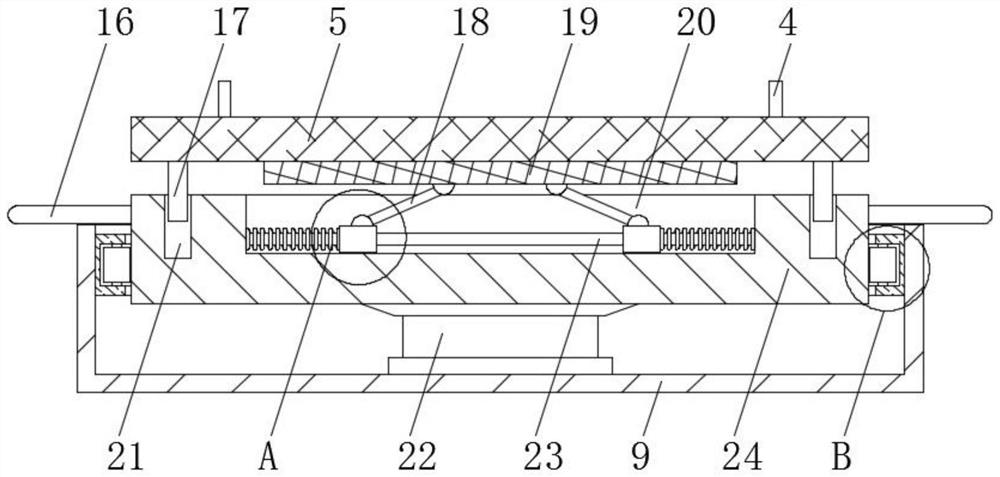

[0034] like Figure 1-5 As shown, the present invention provides a multi-functional press-fitting tool for automobile gearbox parts, including a workbench 8, a support frame 6 is fixedly installed on the top of the workbench 8, and a through groove is formed on the outer wall of the support frame 6, An adjustment plate 1 is slidably connected inside, a fastening bolt 2 is arranged on the top of the support frame 6, a fixing plate 3 is fixedly connected to the right end of the adjustment plate 1, and a clamping block 7 is fixedly connected to both ends of the fixing plate 3, and the fixing plate 3 and the clamping block 7 are located directly above the workbench 8, the top center of the workbench 8 is fixedly installed with a receiving seat 9, the bottom of the inner wall of the receiving seat 9 is rotatably connected with a rotating column 22, and the top of the rotating column 22 is fixedly connected with a rotating column. Circular plate 24 .

[0035] like Figure 1-5 As s...

Embodiment 2

[0037] like Figure 1-5As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, a rectangular groove 20 is formed on the top of the rotating circular plate 24, and a fixed rod 23 is fixedly connected to the inner wall of the rectangular groove 20. The outer wall is slidably connected with a movable hollow block 26, the top of the movable hollow block 26 is hinged with a linkage rod 18, the top of the linkage rod 18 is hinged with a mounting plate 19, and the top of the mounting plate 19 is fixedly connected with a receiving circular plate 5. The top is welded with positioning pins 4, and when the surface of the receiving circular plate 5 is placed with automobile gearbox accessories, the mounting plate 19 can push the linkage rod 18 to move through the weight of the automobile gearbox accessories, so that the linkage rod 18 can push the movable hollow. The block 26 moves, the outer wall of the fixed rod 23 is sleeved with a sprin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap