Gas-liquid mixing device capable of being intelligently controlled

A gas-liquid mixing and gas layer technology, which is applied in the directions of gas/vapor and liquid mixing, mixers with rotary stirring devices, mixers, etc., can solve the problems of inconvenient collection of waste gas, inconvenient control and use, etc. Transmission and remote control, easy to provide power effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

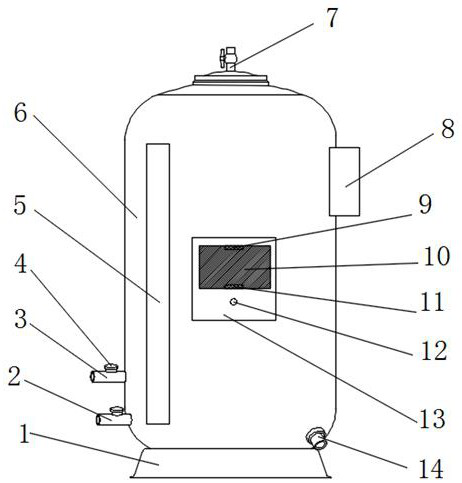

[0021] see figure 1 , 3 , an intelligently controllable gas-liquid mixing device, comprising a base 1, a reaction chamber 6 is fixed on the top of the base 1 by screws, an air inlet 2 is provided on the right side of the bottom of the reaction chamber 6, and an inlet 2 is provided on the upper side of the air inlet 2 The liquid port 3, the air inlet 2 and the liquid inlet 3 are all provided with a flow valve 4, a glass window 5 is fixed on the left side of the front of the reaction chamber 6 by inlaying, and a working box 13 is fixed on the right side of the glass window 5 by screws, and the working box 13 The display 10 is fixed on the top of the front side by screws, which is a touch screen display screen. The upper middle of the display 10 is provided with a speaker 9, and the speaker 9 is fixed on the work box 13 by screws. The monitor 11 is fixed on the work box 13 by screws, a button 12 is provided on the lower side of the sound receiver 11, the button 12 is fixed on th...

Embodiment 2

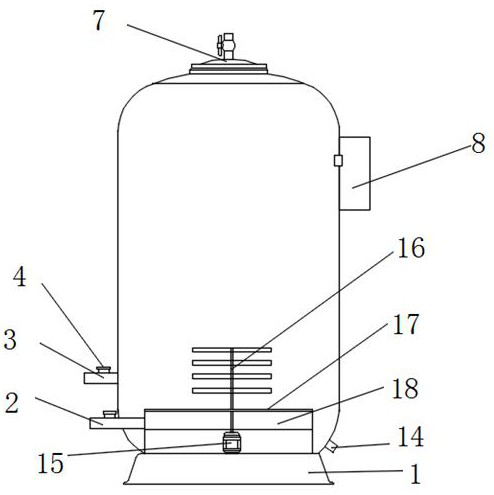

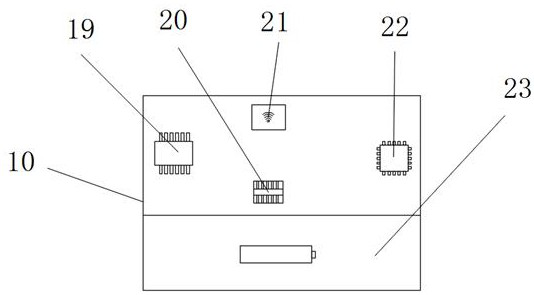

[0024] see figure 1 , 2 3, a gas-liquid mixing device that can be intelligently controlled, including a storage 20, a network interface 21 is arranged on the upper side of the storage 20, and an AI control chip 22 is arranged on the lower right side of the network interface 21. The model is: HXD036, the storage 20. The network interface 21 and the AI control chip 22 are both fixed on the display 10 by screws, the storage 20 is provided with a battery 23 on the lower side, the battery 23 is fixed on the display 10 by screws, and the reaction chamber 6 is provided with a water outlet 14 on the lower side , the top of the reaction chamber 6 is provided with a waste gas collection pipe 7, the upper right side of the reaction chamber 6 is fixed with a vacuum maker 8 by screws, the inner side of the bottom of the reaction chamber 6 is fixed with a motor 15 by screws, and the top of the motor 15 is provided with an air chamber 18. 18 is fixed on the reaction chamber 6 by screws, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com