Intelligent seeder for agricultural planting

An intelligent seeder technology, which is applied to seeder parts, agriculture, seeding, etc., can solve the problems of high labor intensity and low seeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

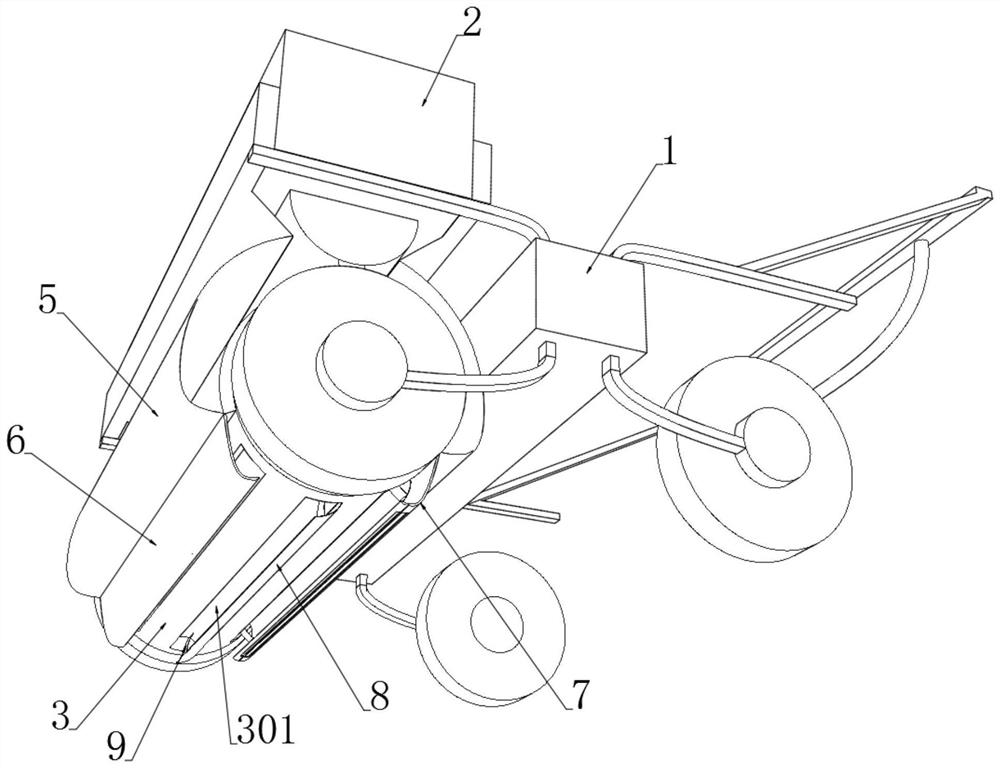

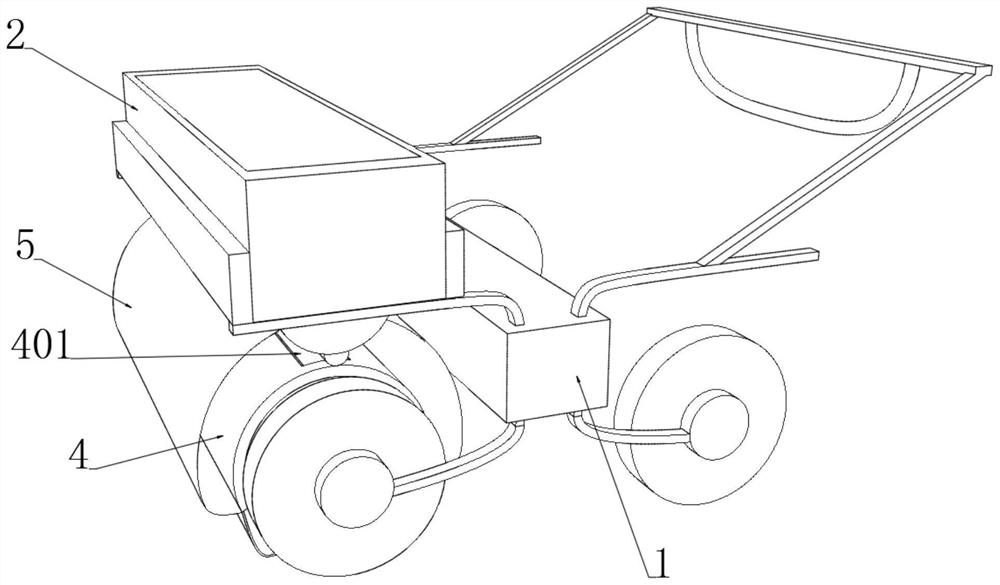

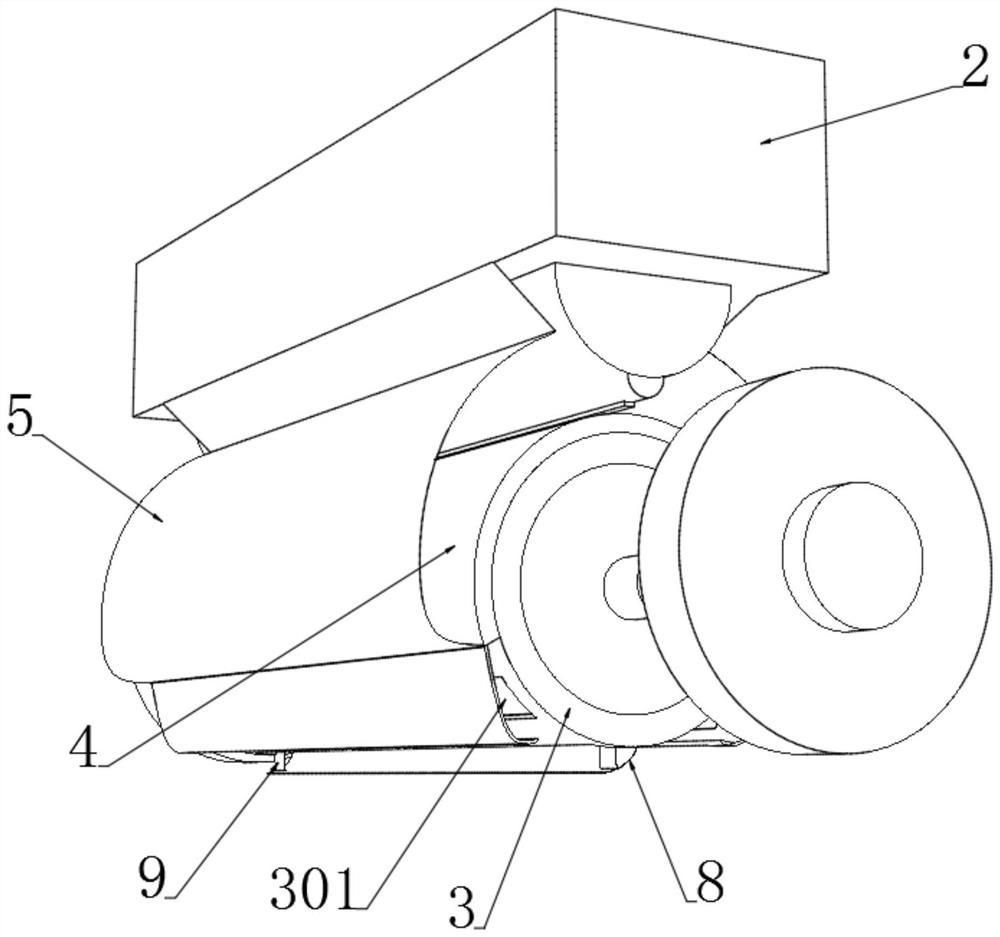

[0045] see Figure 1-3 , an intelligent seeder for agricultural planting, comprising a driving car 1 with two pairs of driving wheels, a feeding box 2 is fixedly installed on the upper end of the front side of the driving car 1, and the feeding port of the feeding box 2 is located at its bottom end, In addition, a quantitative feeding valve is installed at the feeding port of the feeding box 2. Below the feeding box 2, there is a seeding roller 3 located between the front pair of driving wheels. Driven motor, the installation position of the motor can be set according to actual needs, and it can be installed on the frame that supports the drive wheel. The motor drive shaft runs through the center of the drive wheel and is fixedly connected with the seeding roller 3. The drive wheel is rotated and installed on the frame. Above, this is the prior art, do not repeat it here;

[0046] see Figure 3-5 The outer end wall of the seeding roller 3 located on the upper side is movably...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com