Method for optimizing local finite element model of aircraft cabin door and fuselage contact area

An optimization method and finite element technology, applied in design optimization/simulation, instrumentation, geometric CAD, etc., can solve problems such as low calculation accuracy of strain and deformation parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

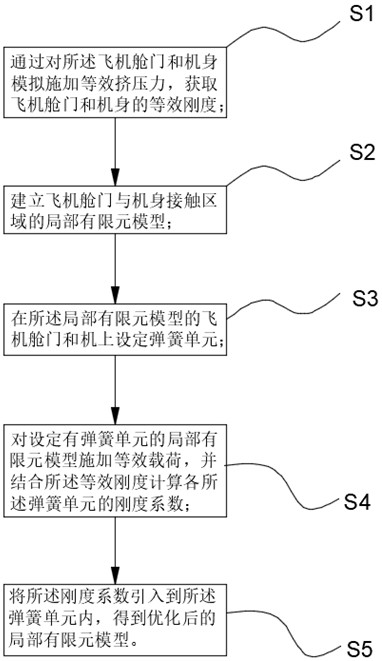

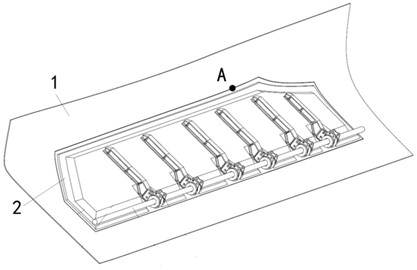

[0054] refer to Figure 1 to Figure 2 , the present application discloses a method for optimizing the local finite element model of the contact area between the aircraft door 2 and the fuselage 1, including the following steps;

[0055] In this embodiment, the combination of figure 2 The shown structure of the aircraft door 2 and the fuselage 1 is a comparative description of each step;

[0056] S1, obtain the equivalent stiffness of the aircraft door 2 and the fuselage 1 by simulating an equivalent pressing force on the aircraft door 2 and the fuselage 1;

[0057] S11, obtain the assembly model of the aircraft cabin door 2 and the fuselage 1, and select a contact point in the assembly model according to the contact mode of the aircraft cabin door 2 and the fuselage 1;

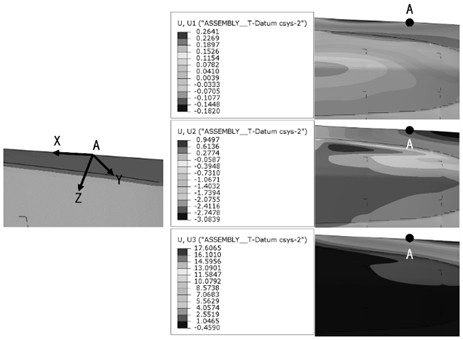

[0058] like figure 2 As shown in the figure, according to the actual working conditions, the position of point A is selected as the contact point; among them, it is marked as A on the aircraft door 2 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com