Camera module appearance detection device and control method

A camera module, appearance inspection technology, applied in measuring devices, optical testing flaws/defects, instruments, etc., can solve the problems of quality problems, camera damage, cracks, etc. of finished products, so as to achieve consistent production quality and accurate computer judgment. , the effect of clear image

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The principles and features of the present invention are described below, and the examples are only used to explain the present invention, but not to limit the scope of the present invention.

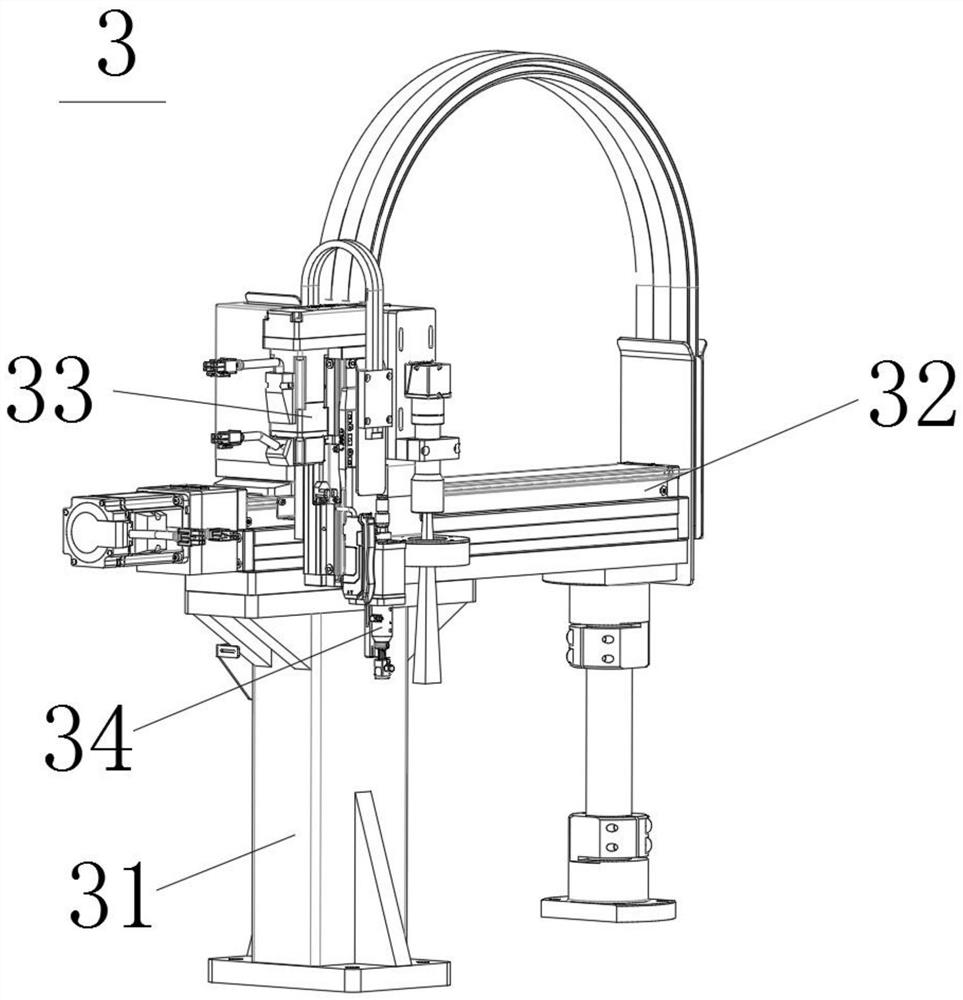

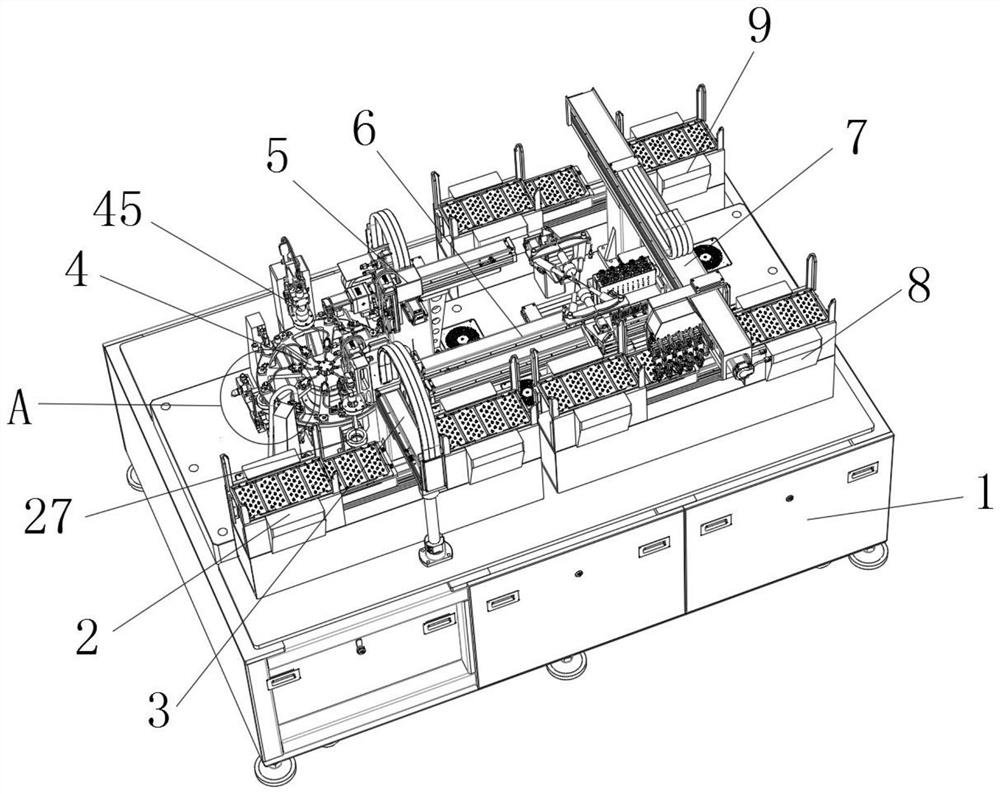

[0038] In a specific embodiment, as Figure 1-7 As shown, a camera module appearance detection device includes a feeding mechanism 2, a first reclaiming mechanism 3, a rotating mechanism 4, a second reclaiming mechanism 5, a linear mechanism 6, a third Material mechanism 7, intact product receiving mechanism 8 and defective product receiving mechanism 9.

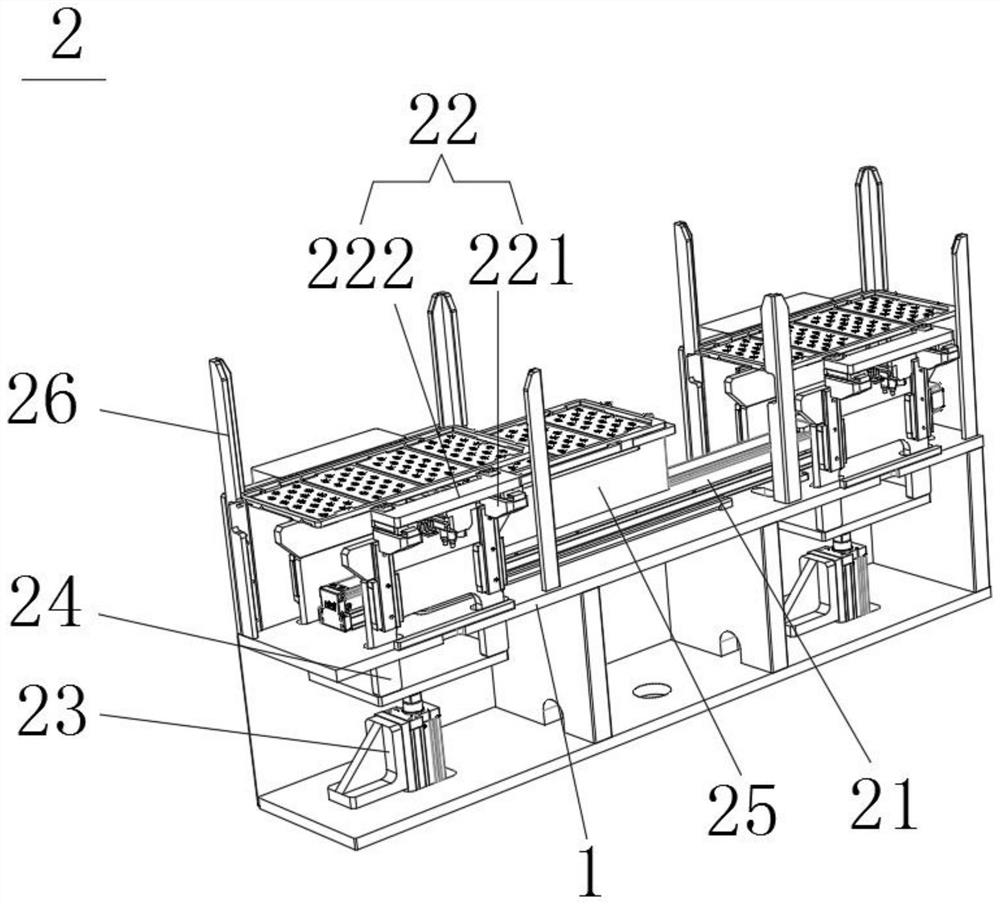

[0039] like figure 2 and image 3As shown, the feeding mechanism 2 includes a first guide rail 21 fixedly arranged on the installation table 1, two clamps 22 and an electric push rod 23 in number, and a bearing is fixed on the driving end of the first guide rail 21 seat 25, the top of the bearing seat 25 is provided with a limit protruding strip 251, and the bottom of the tray is provided with a corresponding slot 253, that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com