Shunt valve and cleaning machine applying shunt valve

A water separation valve and washing machine technology, which is applied to the parts of dishwashing machines/rinsing machines, valve operation/release devices, multi-way valves, etc. Sealing, high risk of water leakage at the connection, etc., to achieve the effect of improving the water separation effect, improving the sealing performance and reliability, and simplifying the assembly method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

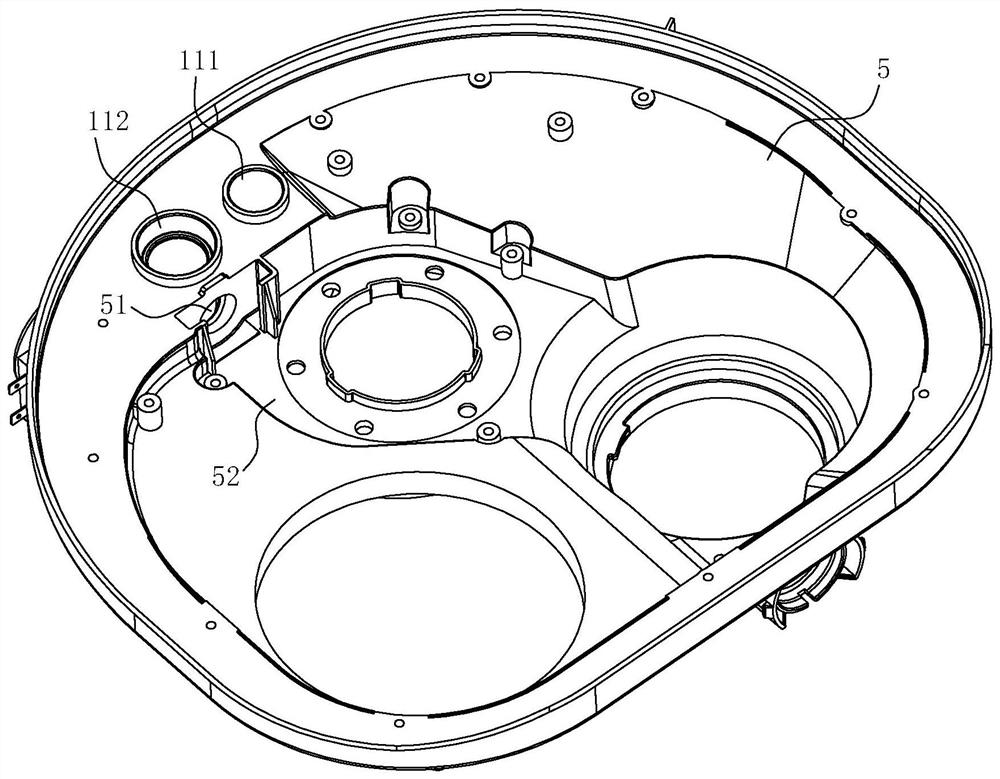

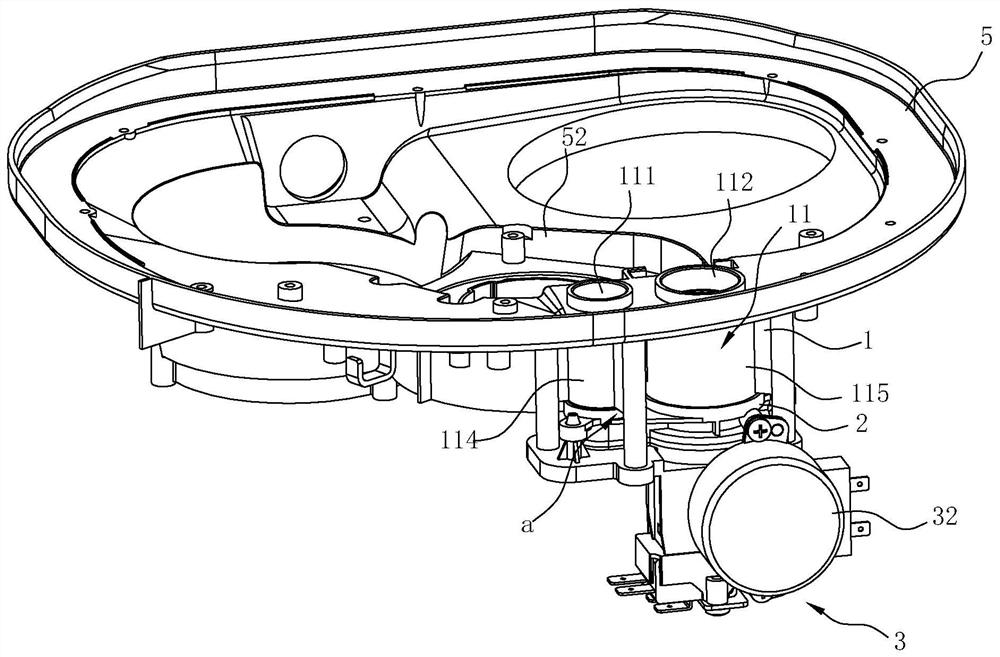

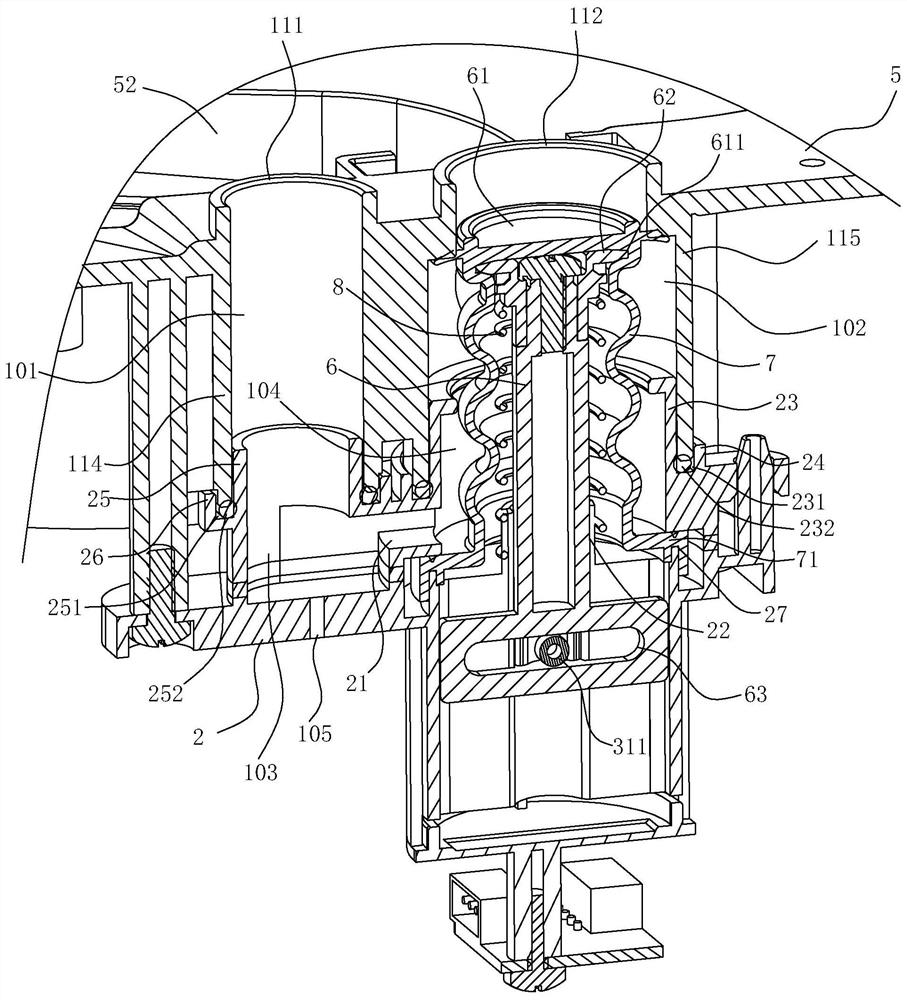

[0035] like Figures 1 to 6 As mentioned above, the water diverter valve in this embodiment includes a casing 1 , a fixed seat 2 , a movable column 6 , a driving component 3 and a control component 4 .

[0036] like figure 2 As shown, the above-mentioned housing 1 has a hollow water separation cavity 11, the side of the water separation cavity 11 has a water inlet 113 for docking with the water outlet 51 of the washing machine, and the top of the water separation cavity 11 has a first The water outlet 111 and the second water outlet 112 . The water separation cavity 11 is vertically arranged with a partition a that can divide it into a first cavity 101 corresponding to the first water outlet 111 and a second cavity 102 corresponding to the second water outlet 112, and the water inlet 113 corresponds to the second cavity 102. The cavity 102 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com