Snow honey production and filling integrated assembly line, production method and snow honey product

A production method and assembly line technology, applied in packaging, bottling machines, liquid handling, etc., can solve the problems of lack of good solutions, lack of variety, monotonous varieties, etc., to enhance the purchase and use experience, increase the aesthetics and Variety category, effect of rich variety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

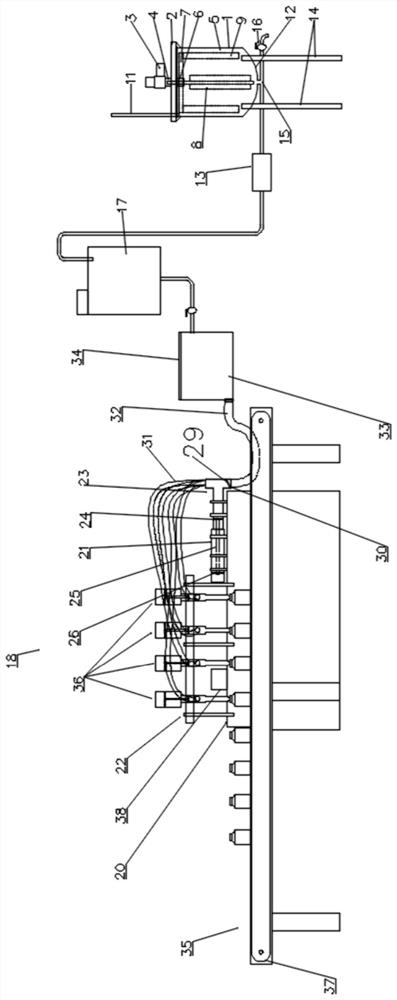

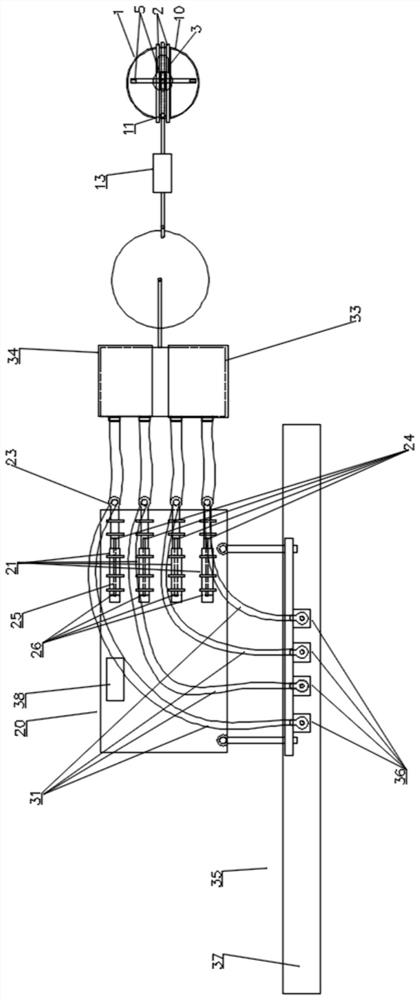

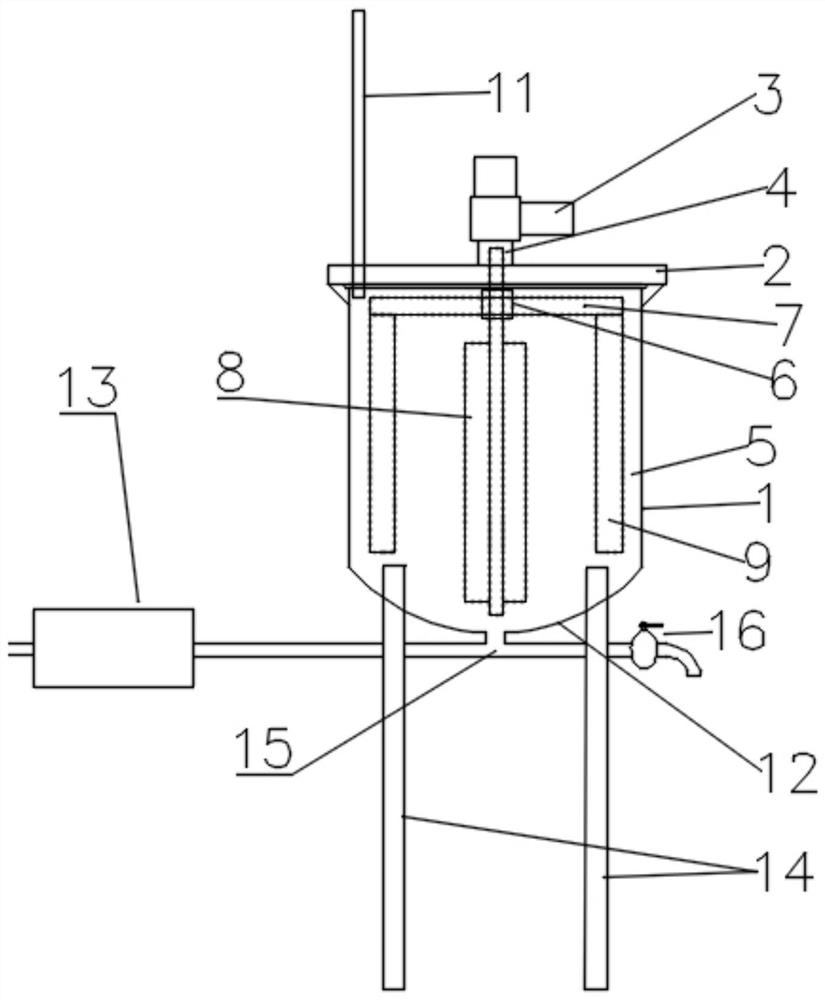

[0026] The stainless steel tank body 1 is a cylindrical structure, a gear motor 3 is fixedly arranged on the upper end face of a stainless steel bracket 2 and the power output shaft of the gear motor 3 is perpendicular to the upper end face of the stainless steel frame 2, and the power output shaft of the gear motor 3 is facing The center of the filling hole of the stainless steel tank 1 extends vertically downward into the tank mouth of the stainless steel tank 1. The power output shaft end of the gear motor 3 is provided with a first locking sleeve 4, and the first locking sleeve 4 of a coaxial double-blade agitator 5 is provided. The two locking sleeves 6 are paired with the first locking sleeve 4 and are connected coaxially. The tank mouth of the stainless steel tank 1 is provided with a reversible dust cover 10; a feeding pipe 11 passes through the stainless steel bracket 2 in the vertical direction. One side of the neutral position is connected to the tank mouth of the st...

Embodiment 2

[0028] The stainless steel bracket 2 is arranged on the upper edge of the tank mouth of the stainless steel tank body 1. The stainless steel bracket 2 is composed of two stainless steel square tubes that are parallel to each other. The outer side of the tank wall at the upper end of the tank body 1 .

Embodiment 3

[0030] A first group of stirring blades 8 is arranged on the central axis of a coaxial double agitator 5, a second locking sleeve 6 is arranged on the upper end of the coaxial double agitator 5, and the sleeve of the second locking sleeve 6 is axially symmetrically arranged Extend the stirring arm 7 , the extension end of the extending stirring arm 7 is perpendicular to the extending stirring arm 7 and a second group of stirring blades 9 are arranged in the vertical direction, and the discharge valve 16 is arranged on the right side of the stainless steel three-way 15 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com