Single-wire cutting machine capable of conducting transverse cutting and longitudinal cutting

A technology of vertical cutting and horizontal cutting, which is applied to fine working devices, manufacturing tools, stone processing equipment, etc., can solve the problems that the worktable can only be fed up and down, low cutting precision, low cutting efficiency, etc., to improve cutting efficiency. , high cutting efficiency, reducing the effect of combined length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

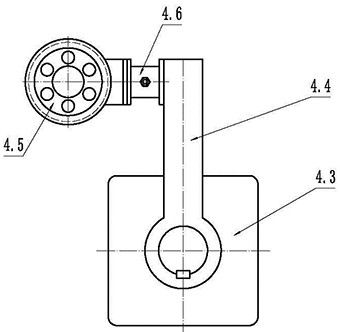

[0029] Embodiment 1, a single wire cutting machine that can cut transversely and longitudinally, such as Figure 1-3 As shown, it includes a base 1, a workbench 2, a cutting assembly 3, a tensioning assembly 4, a wire retracting assembly 5 and a cutting wire 6, characterized in that: the base 1 includes a left column 1.1 and a right column 1.2, the left column 1.1 is fixed on the left side of the base 1, the right column 1.2 is fixed on the right side of the base 1, the left column 1.1 and the right column 1.2 are arranged vertically and parallel, and the left column 1.1 and the right column 1.2 are respectively provided with 2 pieces or 2 pieces With the slide rails 7 arranged in parallel above, the cutting assembly 3 includes a left slide frame 3.1 and a right slide frame 3.2. The left slide frame 3.1 and the right slide frame 3.2 are respectively provided with slide rails 7 on the left column 1.1 and the right column 1.2. The slider 8, the left column 1.1 and the right colu...

Embodiment 2

[0040] like Figure 4 As shown, the worktable 2 includes an upper turntable 2.1 and a lower moving base 2.2, and the upper turntable 2.1 and the lower moving base 2.2 are connected by a rotating shaft 2.3.

[0041] The worktable 2 also includes an upper turntable rotation drive assembly 2.4, the upper turntable rotation drive assembly 2.4 includes a gear 2.4.1 and a rack 2.4.2, the rack 2.4.2 is fixed on the base 1, and the gear 2.4.1 is installed on the base 1. On the rotating shaft 2.3, the gear 2.4.1 meshes with the rack 2.4.2. When the table 2 moves horizontally, the gear 2.4.1 rolls on the rack 2.4.2, driving the upper turntable 2.1 to rotate.

[0042] The upper turntable rotary drive assembly 2.4 also includes a manipulation mechanism 2.4.3, the gear 2.4.1 and the rotating shaft 2.3 are connected by a sliding key, and the manipulation mechanism 2.4.3 can toggle the gear 2.4.1 to slide axially along the rotating shaft 2.3, To achieve the meshing or disengagement of the g...

Embodiment 3

[0047] like Figure 5 As shown, the worktable 2 includes an upper turntable 2.1 and a lower moving base 2.2, and the upper turntable 2.1 and the lower moving base 2.2 are connected by a rotating shaft 2.3.

[0048] The worktable 2 also includes an upper turntable rotation drive assembly 2.4, the upper turntable rotation drive assembly 2.4 includes a gear 2.4.1 and a rack 2.4.2, the rack 2.4.2 is fixed on the base 1, and the gear 2.4.1 is installed on the base 1. On the rotating shaft 2.3, the gear 2.4.1 meshes with the rack 2.4.2. When the table 2 moves horizontally, the gear 2.4.1 rolls on the rack 2.4.2, driving the upper turntable 2.1 to rotate.

[0049] A clutch 2.5 is provided between the gear 2.4.1 and the rotating shaft 2.3.

[0050] The worktable 2 further includes a locking mechanism 2.6, which can lock the upper turntable 2.1 and the lower moving base 2.2.

[0051] The locking mechanism 2.6 can also be installed between the worktable 2 and the base 1 to lock the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com