Catalyst, preparation method thereof and method for converting light olefin and/or alkane into aromatic hydrocarbon

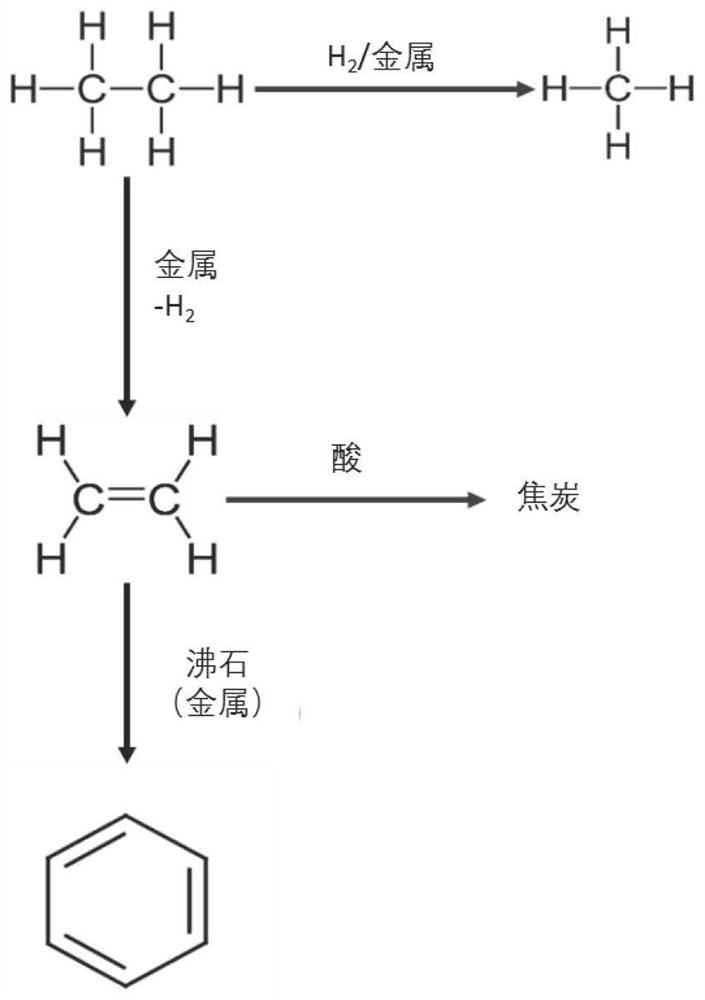

A technology of light olefins and catalysts, which is applied in the direction of catalyst activation/preparation, addition of unsaturated hydrocarbons and saturated hydrocarbons, catalysts, etc., which can solve the problems of increased operating costs of catalysts, achieve good life, and high BTX yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] The molar ratio of nickel nitrate (Ni(NO) was 0.4:1. 3 ) 2 ) and phosphoric acid (H 3 PO 4 )mix. Ammonium hydroxide was added until the pH of the mixture was greater than 7, the mixture was vacuum filtered while washing thoroughly with deionized water, and then dried in an oven at 80 °C overnight, named Sample A with Ni:P 1:1 with NiHPO 4 chemical formula.

Embodiment 2

[0084] Mix 0.1 g of sample A and 10 g of ZSM-5 with a SAR of 30 evenly, then crush it with a hydraulic press, and bake it in air at 550 °C for 4 hours, then sieve it with 20-40 mesh, and the sample is named as sample B. NiHPO 4 The content of Ni:P is 0.18% by weight, and Ni:P is 1:1.

Embodiment 3

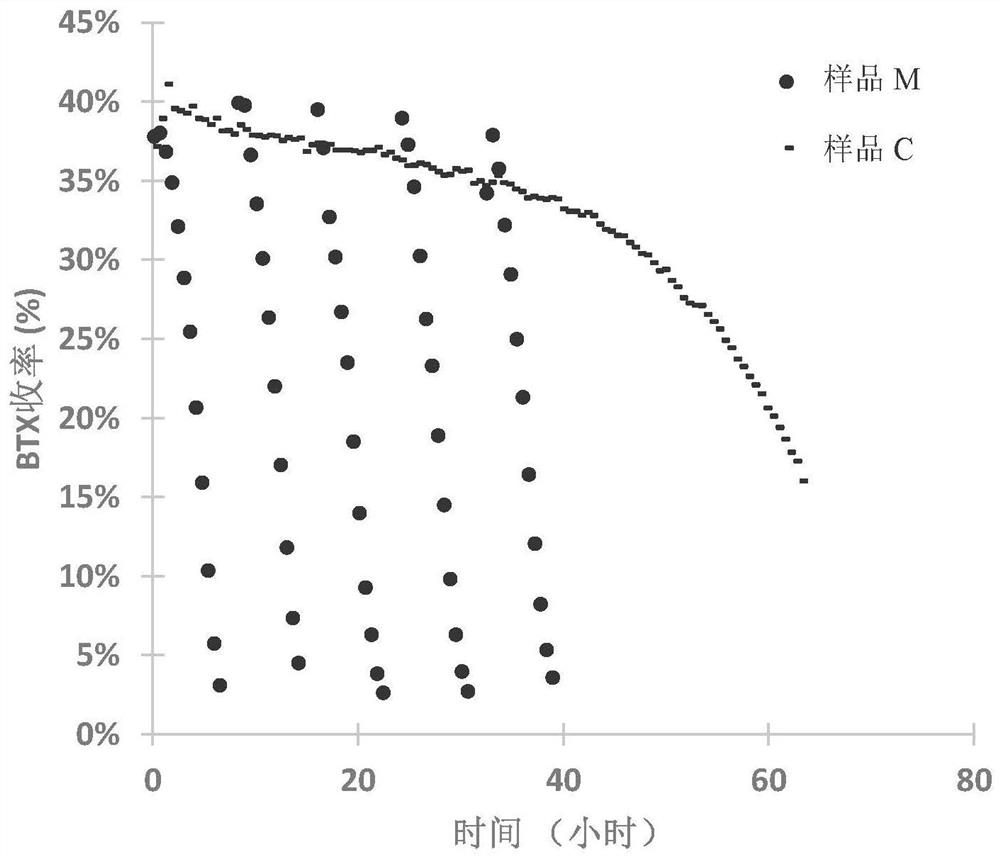

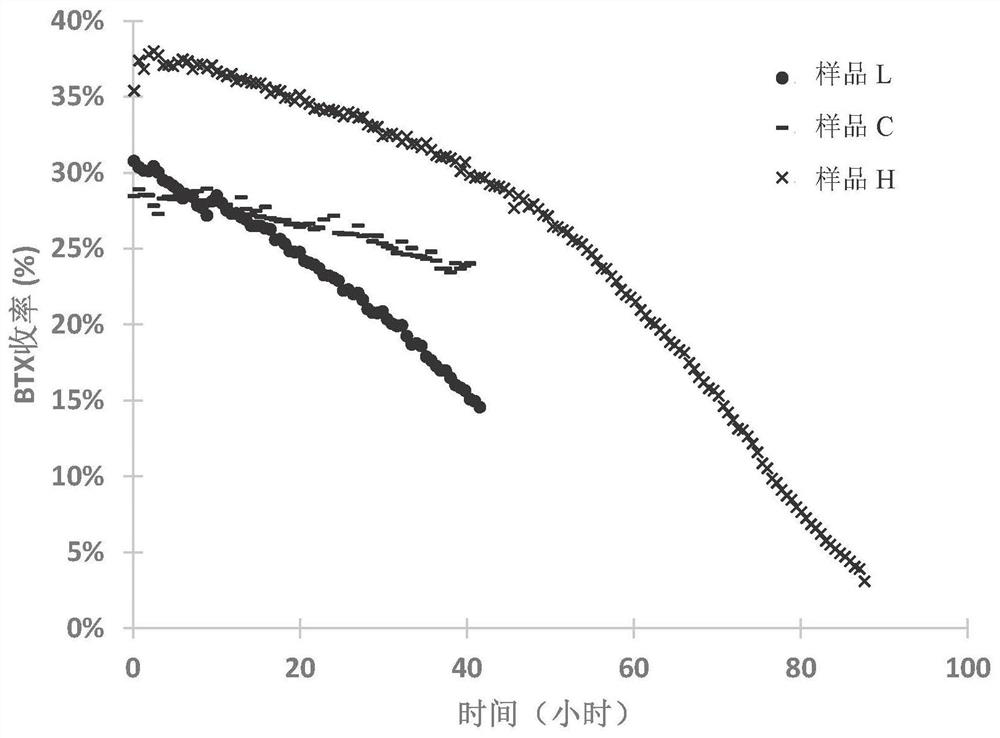

[0086] Sample B was reduced in hydrogen at 630°C for 60 minutes, designated as sample C, which contained nickel phosphide (NiP) and zeolite. Sample C can also be obtained directly from nickel phosphides and zeolites.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com