Bionic lightweight sandwich structure of bipolar plate of fuel cell

A sandwich structure and fuel cell technology, applied to fuel cell parts, collectors/separators, etc., can solve problems such as heavy weight and violation of the lightweight concept, and achieve improved electrical conductivity, good electrical conductivity, and improved distribution effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

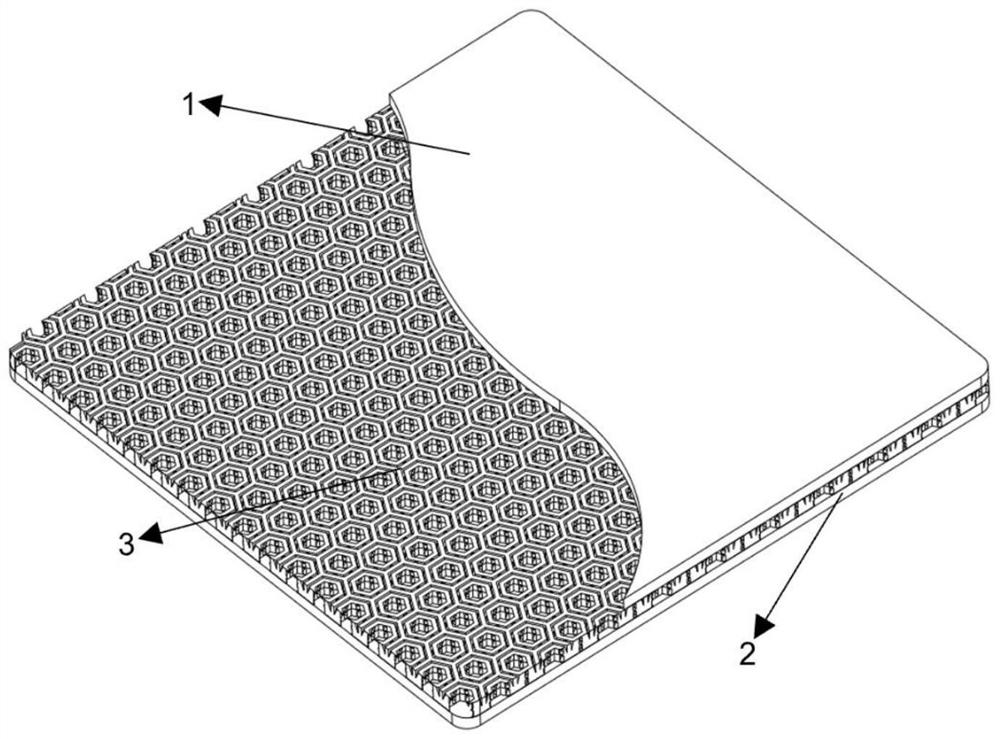

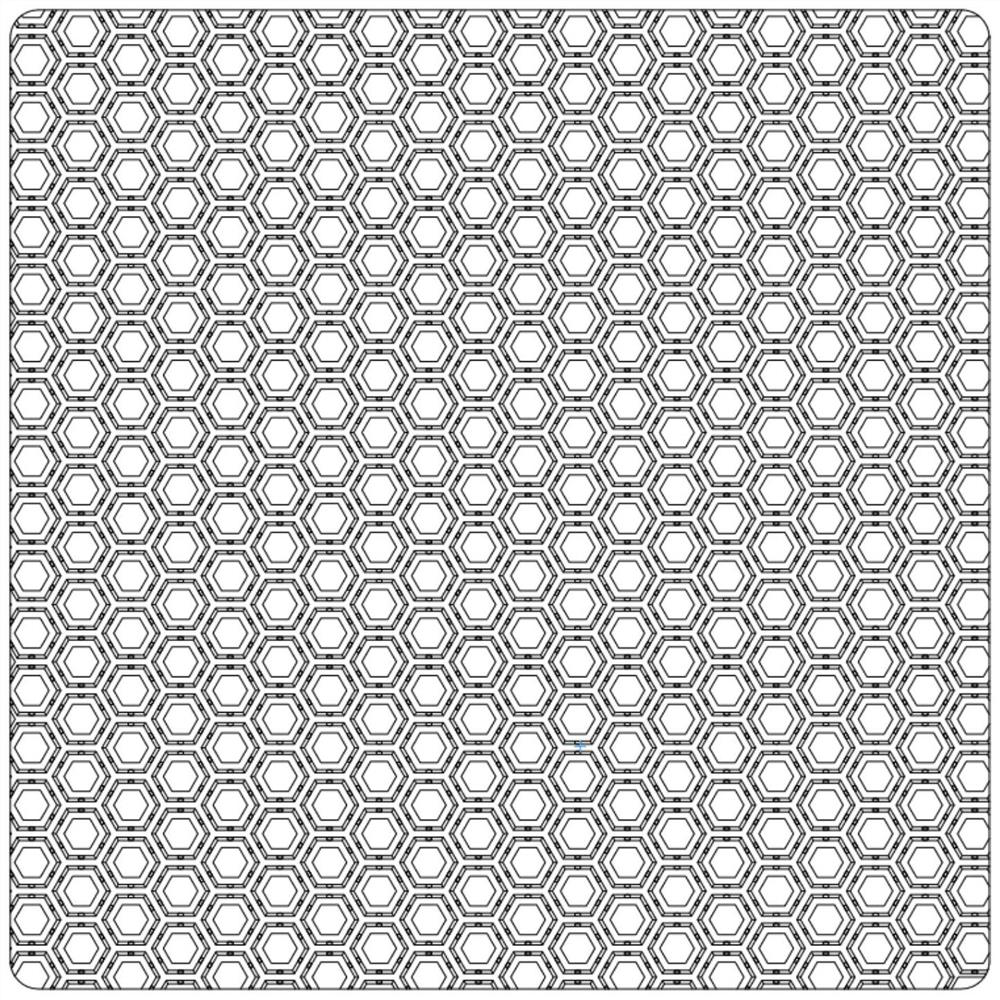

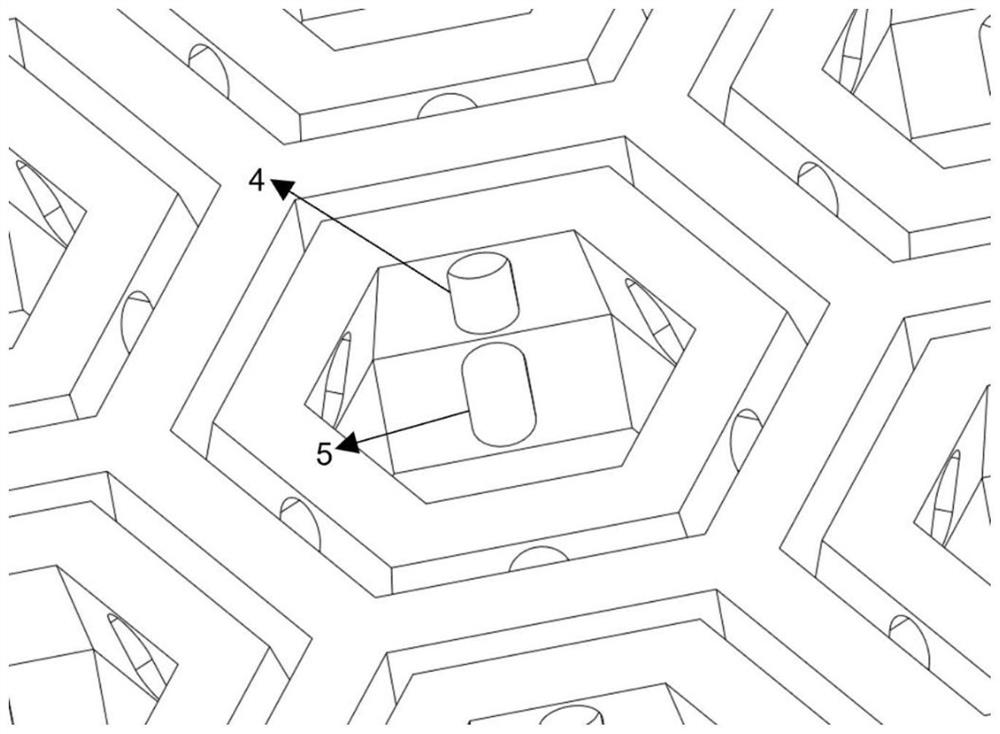

[0032] like figure 1 , a bionic lightweight sandwich structure of a fuel cell bipolar plate, comprising an upper panel 1, a lower panel 2 and a special-shaped honeycomb sandwich structure 3 between the upper panel 1 and the lower panel 2; the upper panel 1 and the lower panel The length, width and height of 2 are 70mm, 70mm and 1.5mm, and the four corners are rounded with a radius of 2mm respectively. figure 2 is the top view of the sandwich structure; image 3 It is a partial enlarged schematic diagram of the sandwich structure, wherein the special-shaped honeycomb sandwich structure 3 includes a fractal thin-walled structure and a traditional honeycomb thin-walled structure stacked in sequence from top to bottom; the height of the special-shaped honeycomb sandwich structure 3 is 2 mm, Including the height of the traditional honeycomb thin-walled structure is 1mm, and the height of the fractal thin-walled structure is 1mm. The special-shaped honeycomb sandwich structure 3 ...

Embodiment 2

[0035] like Figure 5 , a bionic lightweight sandwich structure of a fuel cell bipolar plate, comprising an upper panel 1, a lower panel 2 and a special-shaped honeycomb sandwich structure 3 between the upper panel 1 and the lower panel 2; the upper panel 1 and the lower panel The length, width and height of 2 are 70mm, 70mm and 1.5mm, and the four corners are rounded with a radius of 2mm respectively. Image 6 is the top view of the sandwich structure; Figure 7 is a partially enlarged schematic diagram of the sandwich structure, in which,

[0036] The special-shaped honeycomb sandwich structure 3 includes a fractal thin-walled structure and a traditional honeycomb thin-walled structure stacked in sequence from top to bottom; the height of the special-shaped honeycomb sandwich structure 3 is 2 mm, including the traditional The thin-walled structure has a height of 1mm.

[0037] The special-shaped honeycomb sandwich structure 3 is formed by connecting several side walls, an...

Embodiment 3

[0040] like Figure 9, a bionic lightweight sandwich structure of a fuel cell bipolar plate, comprising an upper panel 1, a lower panel 2 and a special-shaped honeycomb sandwich structure 3 between the upper panel 1 and the lower panel 2; the upper panel 1 and the lower panel The length, width and height of 2 are 70mm, 70mm and 1.5mm, and the four corners are rounded with a radius of 2mm respectively. Figure 10 is the top view of the sandwich structure; Figure 11 is a partially enlarged schematic diagram of the sandwich structure, in which,

[0041] The special-shaped honeycomb sandwich structure 3 includes a fractal thin-walled structure and a traditional honeycomb thin-walled structure stacked in sequence from top to bottom; the height of the special-shaped honeycomb sandwich structure 3 is 2mm, including the traditional The thin-walled structure has a height of 1mm.

[0042] The special-shaped honeycomb sandwich structure 3 is formed by connecting several side walls, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap