High-performance modified asphalt wearing layer rut sample forming device

A technology of modified asphalt and forming equipment, which is applied in the direction of measuring equipment, test sample preparation, sampling, etc., can solve the problems that affect the test efficiency and make it inconvenient for the test personnel to take and place the forming modules, so as to improve the accuracy and convenience Pick and place and installation, practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

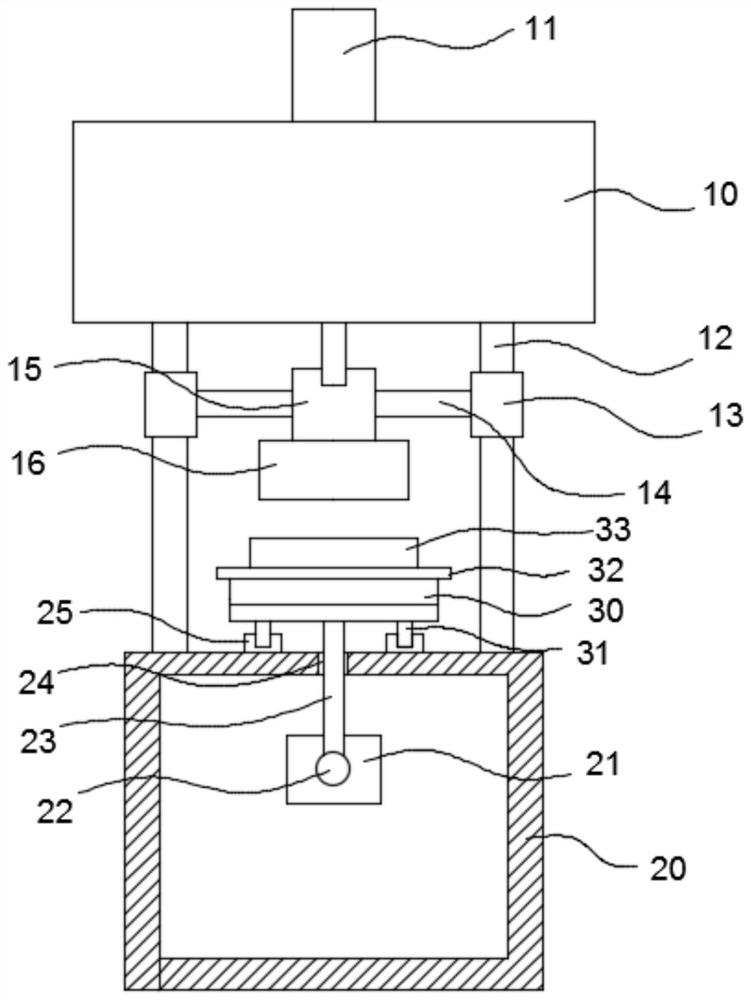

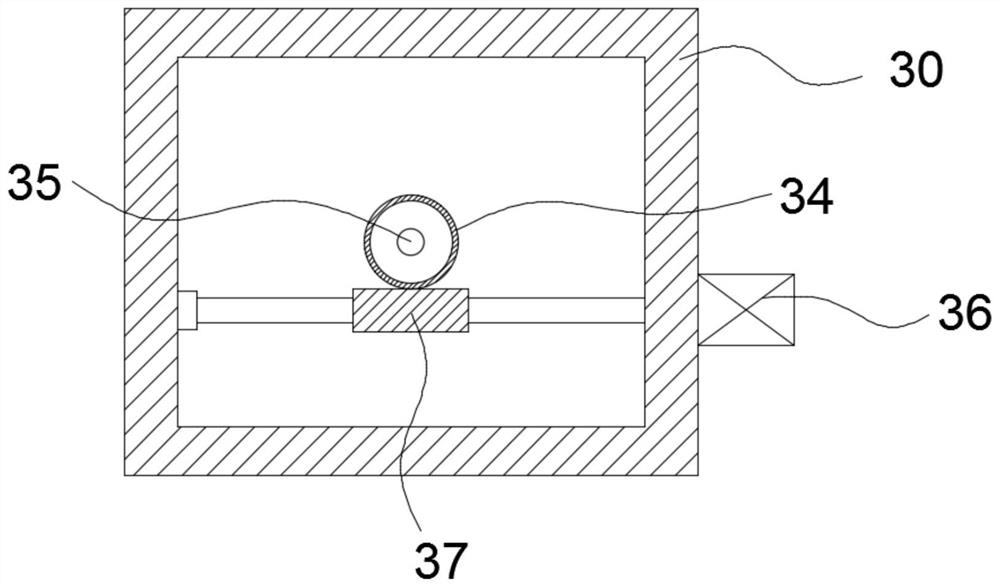

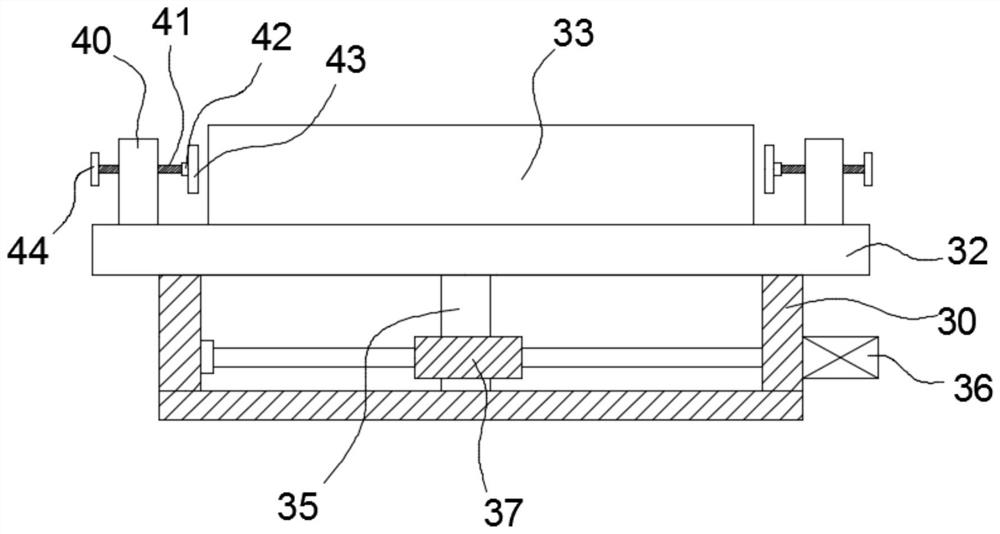

[0019] like Figure 1-3 As shown, the present invention provides a high-performance modified asphalt wear layer rutting sample forming device, comprising:

[0020] Bottom box 20. Guide columns 12 are vertically arranged on both sides of the top of the bottom box 20. A control box 10 is arranged laterally at the top of the guide column 12. A hydraulic cylinder 11 is arranged in the middle of the top of the control box 10. The output end of the bottom of the hydraulic cylinder 11 passes through the control box 10 , and the bottom of the output end is provided with a connecting seat 15 , the two side walls of the connecting seat 15 are laterally provided with connecting rods 14 , and the outer ends of the connecting rods 14 are provided with movable connecting rods 14 . Sleeve 13, the movable sleeve 13 is movably arranged on the outer wall of the guide column 12, and the bottom of the connecting seat 15 is provided with a rutting die 16;

[0021] A pair of chute 25 is longitudin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com