Urban sewage treatment equipment

A technology for treatment equipment and urban sewage, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. The effect of time and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to facilitate the understanding of the present invention, the present invention will be described more fully below with reference to specific embodiments.

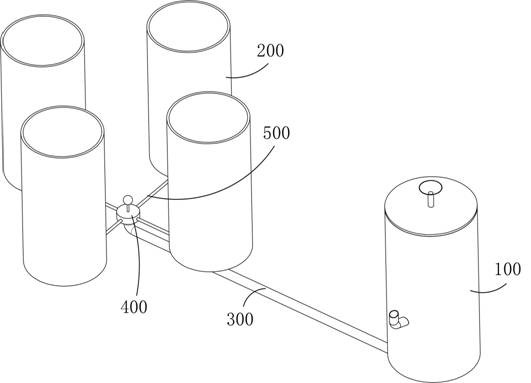

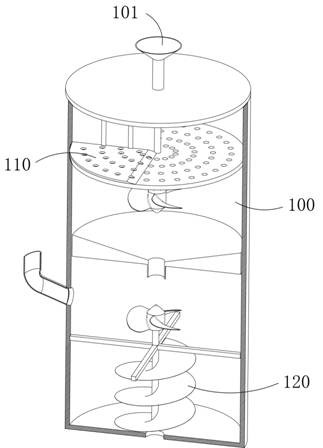

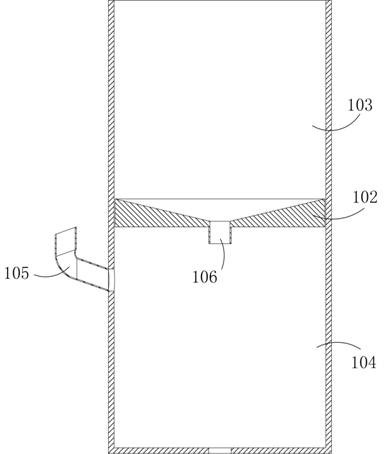

[0039] like Figure 1-7 As shown, an urban sewage treatment equipment includes a filter tank 100 and at least two sedimentation tanks 200. A partition plate 102 is fixed horizontally in the filter tank 100, and the partition plate 102 divides the inner cavity of the filter tank 100 into a The upper filter area 103 and the lower dosing area 104 are provided with through holes on the partition plate 102 .

[0040] The filter area 103 is provided with a filter element 110 for filtering the waste water and automatically collecting the waste located on the filter plate 111 .

[0041] A stirring part 120 for mixing sewage and chemical reagents evenly is arranged in the dosing area 104 .

[0042] The bottom of the filter tank 100 is connected with a connecting main pipe 300 , and the bottom of the sedimentation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com