Landing leg structure with variable lap joint length and wheeled crane

A technology of lap joint length and outriggers, which is applied to cranes and other directions, can solve problems such as strengthening the strength of lap joints, and achieve the effects of improving overall strength, lifting capacity and stability, and increasing extension length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

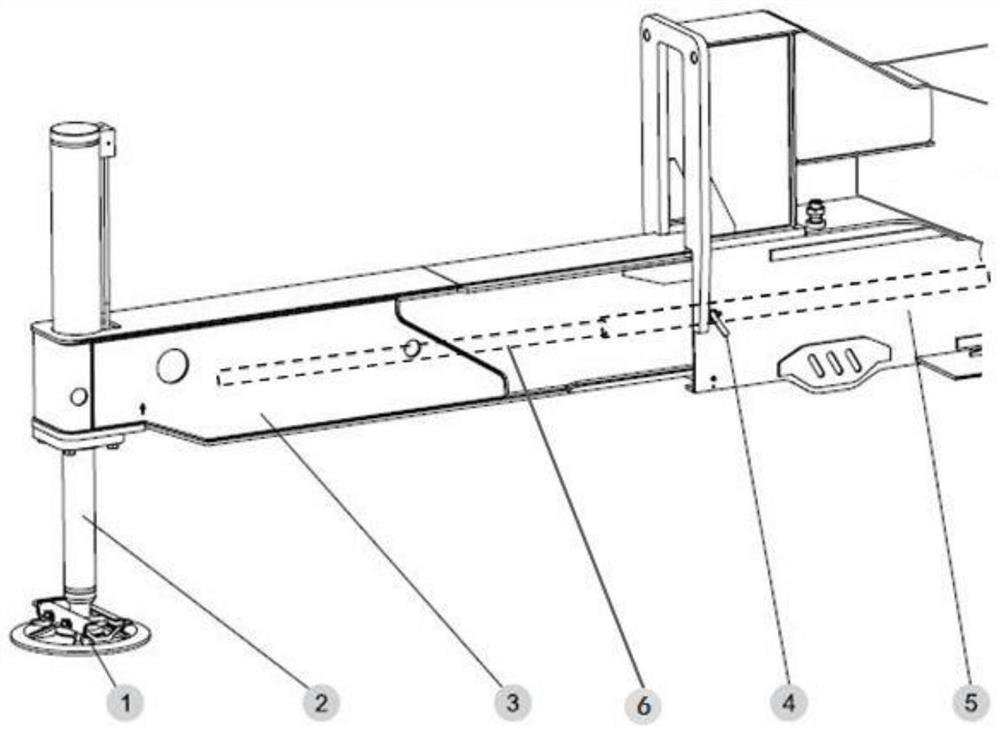

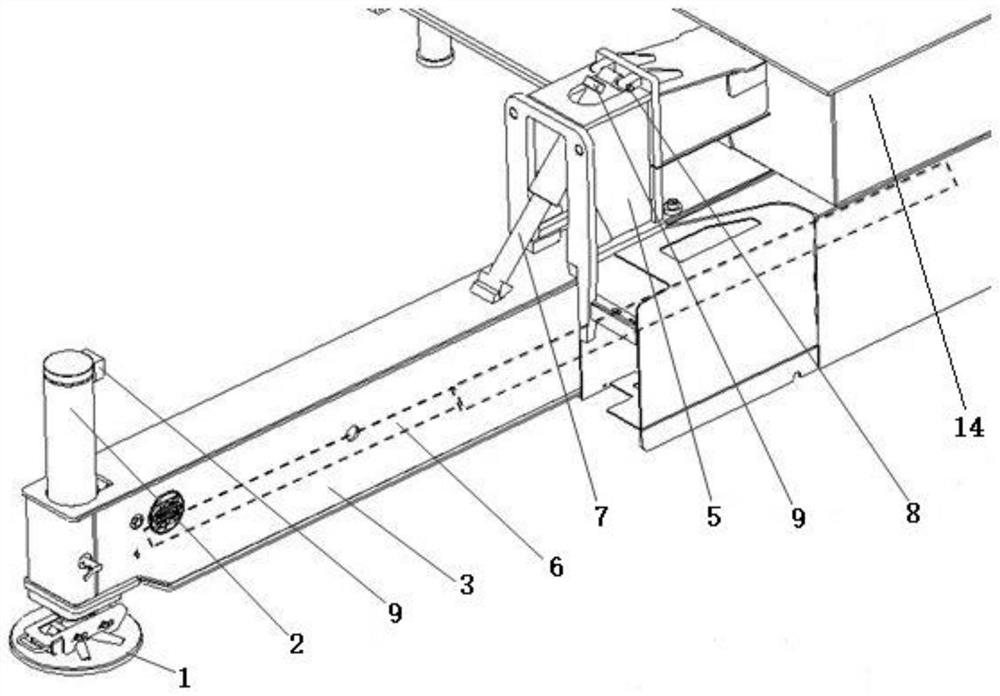

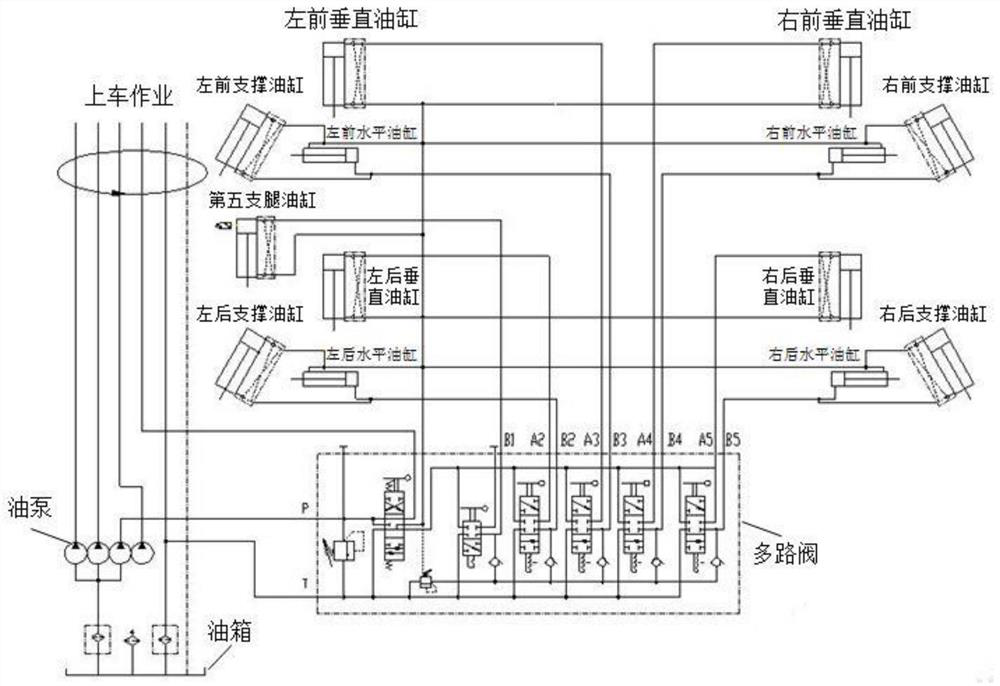

[0029] The variable lap length outrigger structure proposed by the present invention mainly includes: frame 14, fixed outriggers 5, movable outriggers 3, vertical oil cylinder 2, foot plate 1, horizontal oil cylinder 6, support oil cylinder 7, pin shaft 8, hydraulic Two-way lock 9. Hydraulic oil pipe.

[0030] One end of the horizontal oil cylinder 6 is fixed on the fixed outrigger 5, and the other end is fixed on the movable outrigger 3, and the main function is to drive the movable outrigger 3 to move.

[0031] The fixed outrigger 5 is a box-shaped structure, which is formed by tailor welding of plates, and is used to connect the movable outrigger 3 and the frame 14 and is welded on the frame 14 .

[0032] The movable outrigger 3 is driven by the horizontal oil cylinder 6 to move left and right in the fixed outrigger 5 . The outer end of the movable outrigger 3 can be installed with a vertical oil cylinder 2 , and the end of the vertical oil cylinder 2 is connected to the fo...

Embodiment 2

[0037] The support cylinder 7 is replaced by a retractable steel pipe structure, and is locked by a manual latch, such as Figure 5 As shown, the telescopic steel pipe includes a rotating steel pipe 12 and a sliding steel pipe 10. One end of the rotating steel pipe 12 is hinged on the fixed outrigger or the frame through the pin II, and can rotate around the hinge point. The sliding steel pipe 10 can slide in the rotating steel pipe 12. One end of the sliding steel pipe 10 can be matched with the supporting point on the movable outrigger 3 , and the rotating steel pipe 12 and the sliding steel pipe 10 are provided with corresponding pin shaft holes. During operation, the pin shaft I passes through the pin shaft holes on the sliding steel pipe 10 and the rotating steel pipe 12 to limit the relative sliding between the steel pipes. The disadvantage of this solution is that the operation efficiency is low and the use is inconvenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com