Welding material production equipment

A technology for production equipment and welding consumables, which is applied in the field of welding consumables production equipment, can solve problems such as deformation and damage of welding rods, affect the rolling detection of welding rods, and achieve the effect of preventing cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

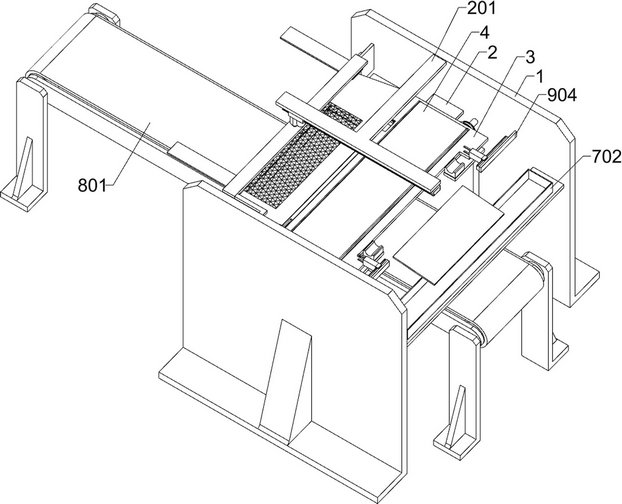

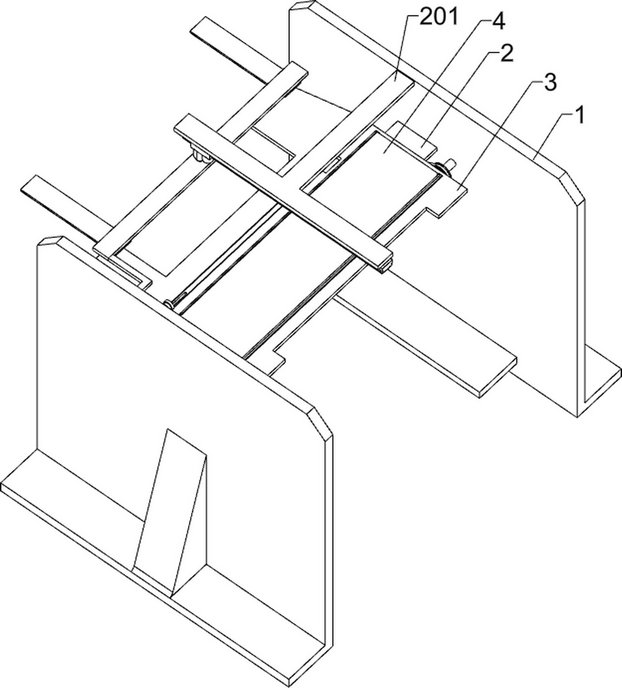

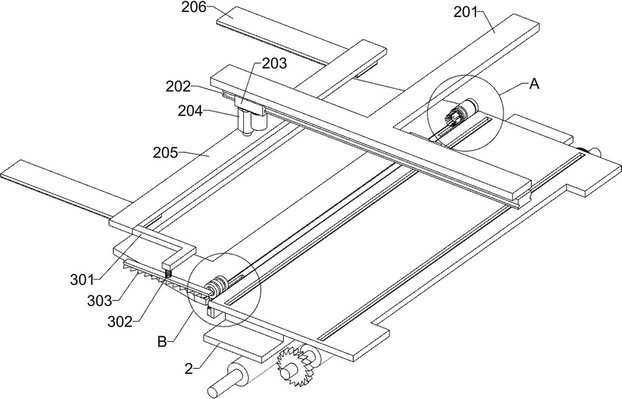

[0036] A welding material production equipment, such as Figure 1-18 As shown, it includes a first installation frame 1, a first installation plate 2, a receiving plate 3 and a detection paper 4; a first installation plate 2 is welded on the upper part of the two first installation frames 1; the upper side of the first installation plate 2 The receiving plate 3 is welded; the upper right part of the receiving plate 3 is provided with the detection paper 4; There are two strip-shaped through grooves for detecting the passing of the paper 4; it also includes a first sleeve 406, a second sleeve 407, a second mounting plate 5, a first camera 6, a first power unit, a first Two power units and a push unit; a second mounting plate 5 is welded to the lower left part of the receiving plate 3; two first cameras 6 are fixedly connected to the lower right side of the second mounting plate 5, and the two first cameras 6 are symmetrical in front and back setting; a first power unit is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com