Dust-free anti-splashing intelligent crushing device for recycled concrete manufacturing

A recycled concrete and crushing device technology, which is applied in the fields of dust removal, transportation and packaging, cleaning methods and utensils, etc., can solve the problems of uneven crushing force, small particle aggregate crushing, and particle size difference of crushed stones, etc., and achieve reduction in advance The probability of damage, the effect of increasing the degree of crushing, and increasing the useful power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative efforts shall fall within the protection scope of the present invention.

[0026] see Figure 1-Figure 8 , the present invention provides technical scheme:

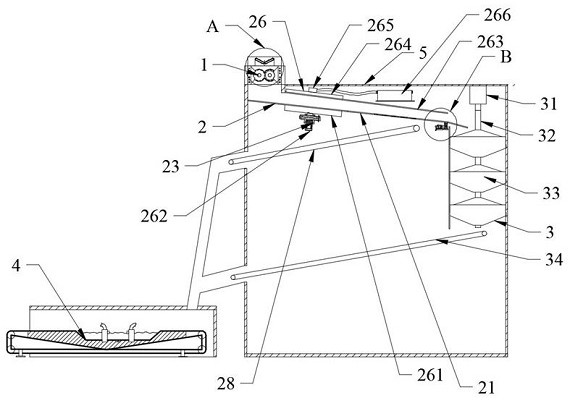

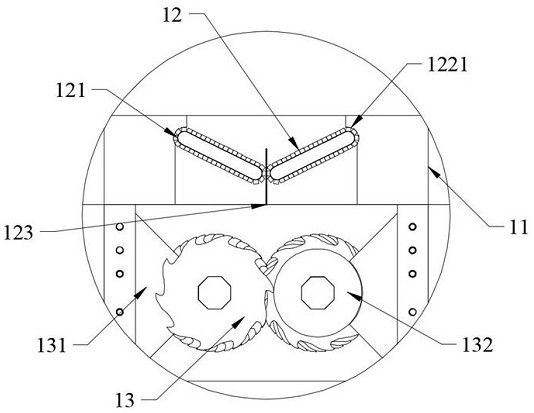

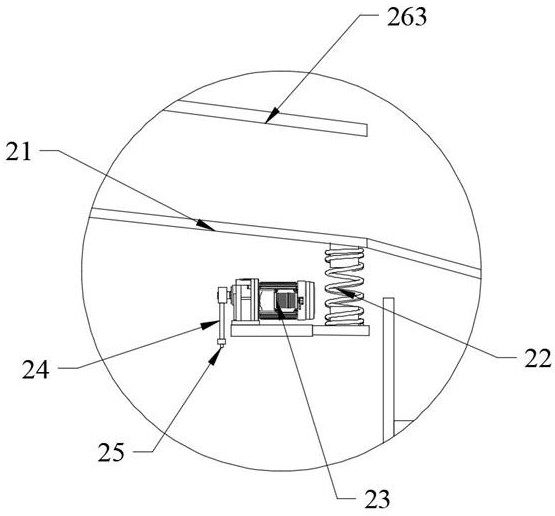

[0027] like Figure 1-Figure 8As shown, a dust-free and splash-proof recycled concrete manufacturing intelligent crushing device, the crushing device includes a feed assembly 1, a primary separation assembly 2, a secondary separation assembly 3, a cleaning assembly 4, an outer box 5, and an outer box The body 5 is firmly connected with the ground, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com