Dual-purpose performance testing device and method for ultra-high-speed rolling bearing and gas thrust bearing

A rolling bearing and thrust bearing technology, which is applied in the field of dual-purpose performance testing devices for ultra-high-speed rolling bearings and gas thrust bearings, can solve the problems of inability to accurately simulate the running state of the bearing and errors in the evaluation and evaluation of bearing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

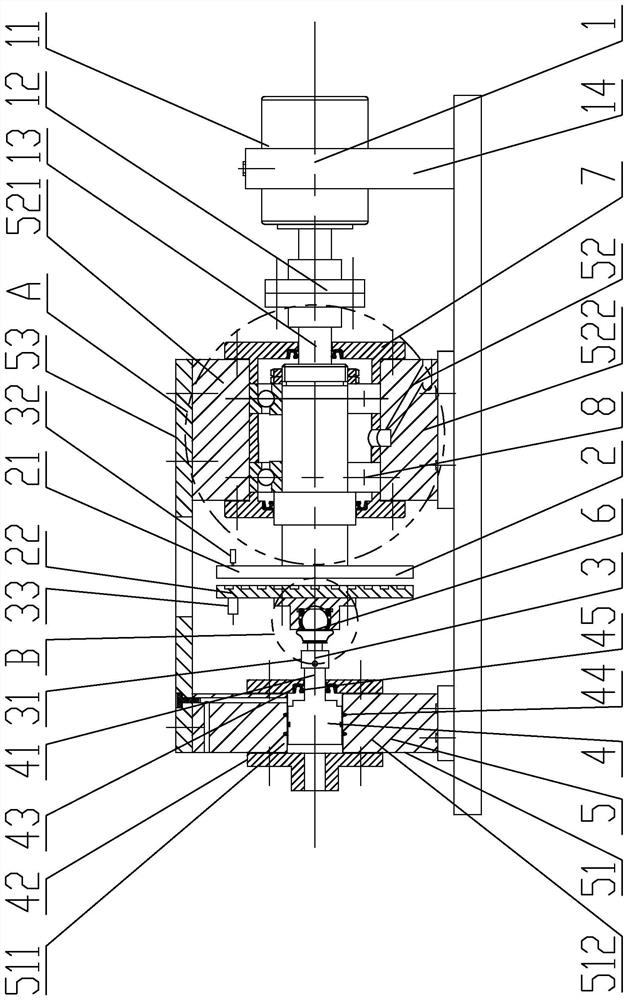

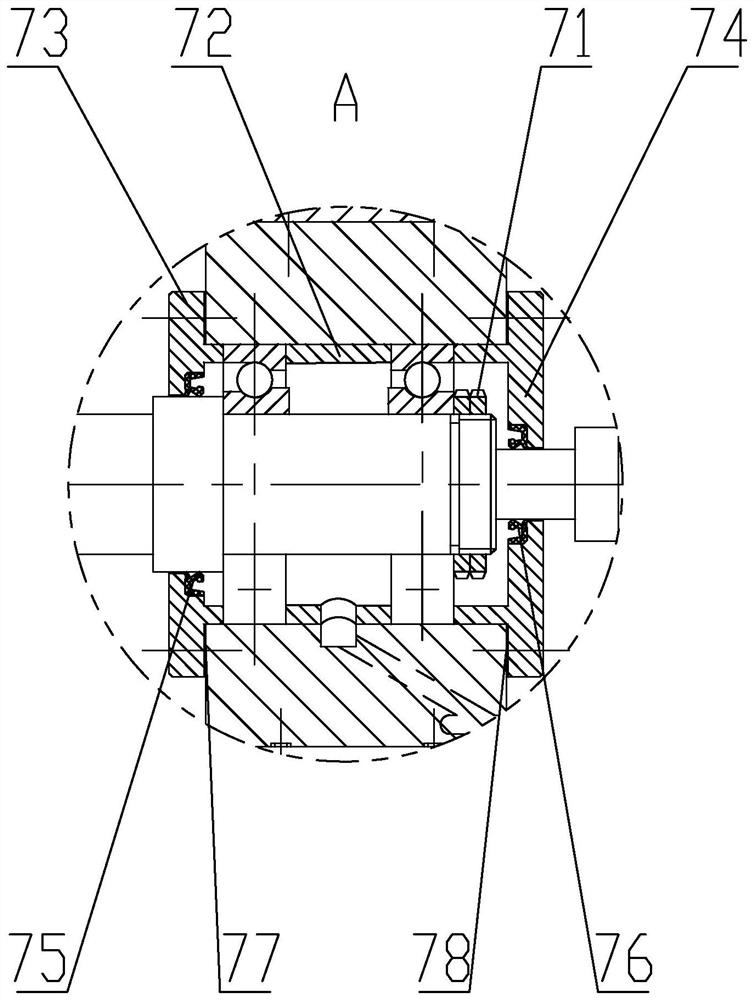

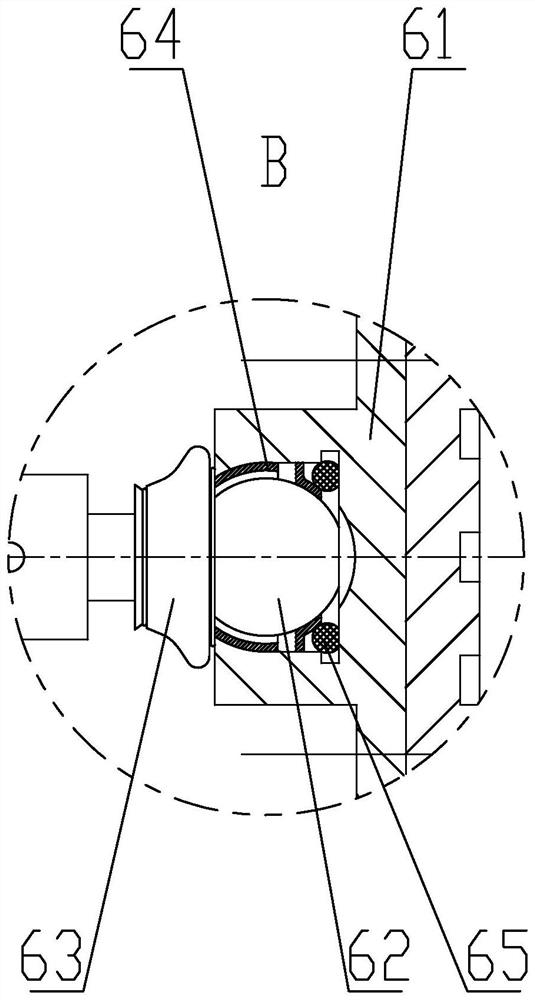

[0026] Embodiment 1: Combining Figure 1 to Figure 4 This embodiment will be described. A dual-purpose performance testing device for a super-high-speed rolling bearing and a gas thrust bearing of this embodiment includes a rotary drive structure 1 , a spiral groove gas bearing 2 , a sensor structure 3 , an axial displacement control structure 4 , and a chassis 5 , ball and socket connection structure 6, axial positioning structure 7 and ultra-high-speed rolling bearing 8, the case 5 includes a split piston support box 51 and a split rolling bearing support box 52, and the spiral groove gas bearing 2 is vertically and coaxially arranged in the split type Between the piston support box 51 and the split rolling bearing support box 52 , the spiral groove gas bearing 2 includes a rotating thrust plate 21 and a spiral groove air floating plate 22 arranged in parallel opposite to each other, and the spiral groove air floating plate 22 is close to the rotating thrust plate 21 One end...

specific Embodiment approach 2

[0031] Specific implementation mode 2: Combining figure 1 Describing this embodiment, the axial displacement control structure 4 of this embodiment further includes a felt ring 44 and a first lip seal 45 , and a sealing recess is machined on the inner wall of the piston assembly through hole of the split piston support box 51 along the circumferential direction. The felt ring 44 is embedded in the sealing groove, the plug portion of the piston rod 41 is slidably connected to the split piston support box 51 through the felt ring 44, and the inner wall of the center hole of the right end cover 43 of the hydraulic cylinder is radially machined with The first annular sealing groove, the first lip-shaped sealing ring 45 is embedded in the first annular sealing groove, and the right end cover 43 of the hydraulic cylinder is slidably and sealingly connected to the rod portion of the piston rod 41 through the first lip-shaped sealing ring 45 . In this way, in order to prevent the leak...

specific Embodiment approach 3

[0032] Specific implementation mode three: combination figure 1 Describing this embodiment, the split-type piston support box 51 of this embodiment includes an upper piston support box 511 and a lower piston support box 512 , the upper piston support box 511 is fixed on the lower piston support box 512 by screws, and the upper piston support box 511 is fixed on the lower piston support box 512 by screws. The support box 511 is internally processed with a first oil circuit that communicates with the rod cavity of the hydraulic cylinder, and the other end of the first oil circuit is connected to an external oil tank and an oil pump through an oil delivery pipe; the split rolling bearing support box 52 includes an upper rolling bearing support box 521 and the lower rolling bearing support box 522, the upper rolling bearing support box 521 is fixed on the lower rolling bearing support box 522 by screws, and the lower rolling bearing support box 522 is internally machined with a sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com