Pipeline filter pressure testing machine

A pipeline filter and pressure testing technology, which is applied in the testing of machine/structural components, testing of mechanical components, and by measuring the rate of increase and deceleration of fluids, can solve the problem of reducing detection efficiency, affecting detection accuracy, and uneven pressure distribution and other issues to achieve the effect of improving accuracy, improving the effect of detection, and strengthening stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

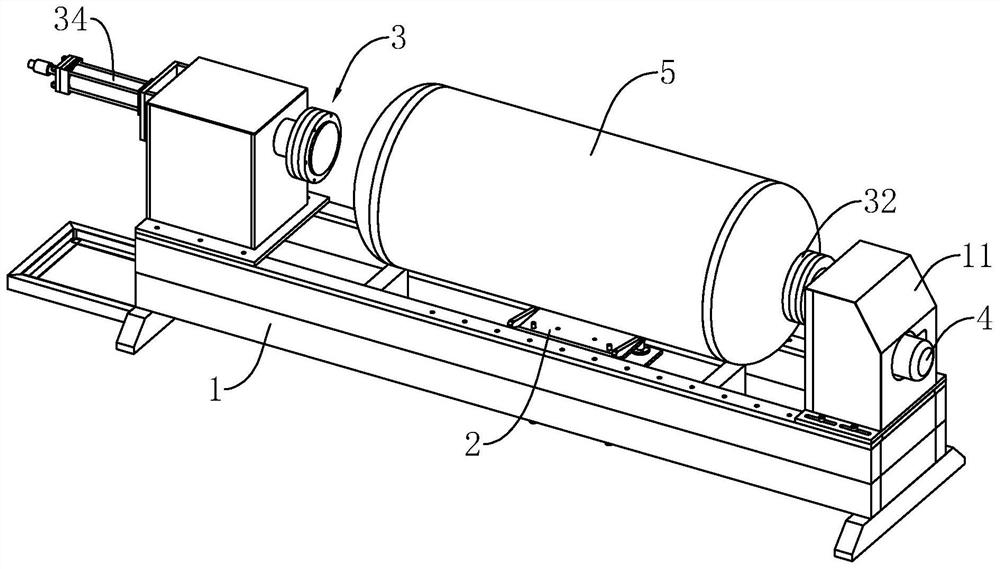

[0042] refer to figure 1 , the pressure testing machine includes a base 1, a support component 2 installed on the base 1, a support component 3 installed above the base 1, and a rotating component 4 installed on the base 1 to drive the support component 3 to rotate. There is a pipeline filter 5, the support component 2 is used to send the pipeline filter 5 between the supporting components 3, and the rotating component 4 can also charge air into the pipeline filter 5 for pressure testing.

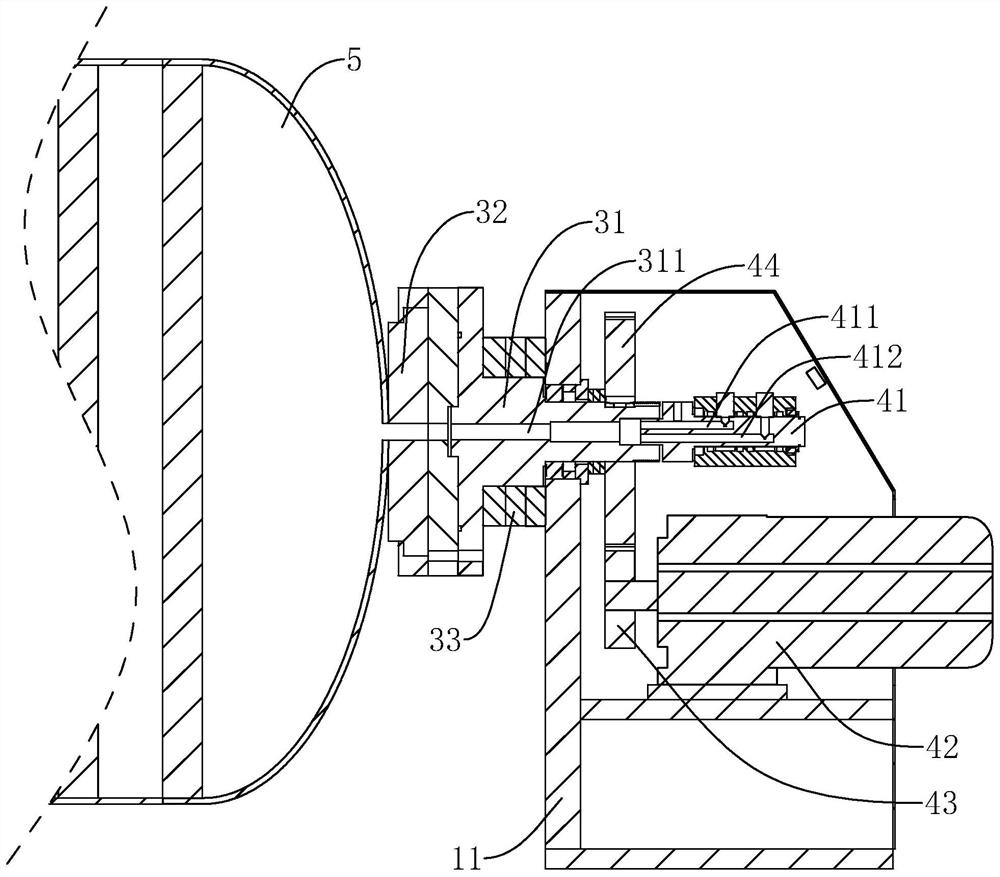

[0043] refer to figure 1 and figure 2 , the two ends of the base 1 are fixedly connected with the positioning box 11, and the holding assembly 3 includes a rotating shaft 31 that rotates on the positioning box 11, an abutting member installed on the rotating shaft 31, and a fixed connection on the positioning box 11 to drive the rotating shaft 31 to slide. The cylinder 34 is clamped, and the abutting member includes an elastic pad 32 sleeved on the end of the rotating shaft 31 and abutti...

Embodiment 2

[0054] The difference between this embodiment and Embodiment 1 is that the driving source for driving the supporting plate 27 to ascend and descend is different. .

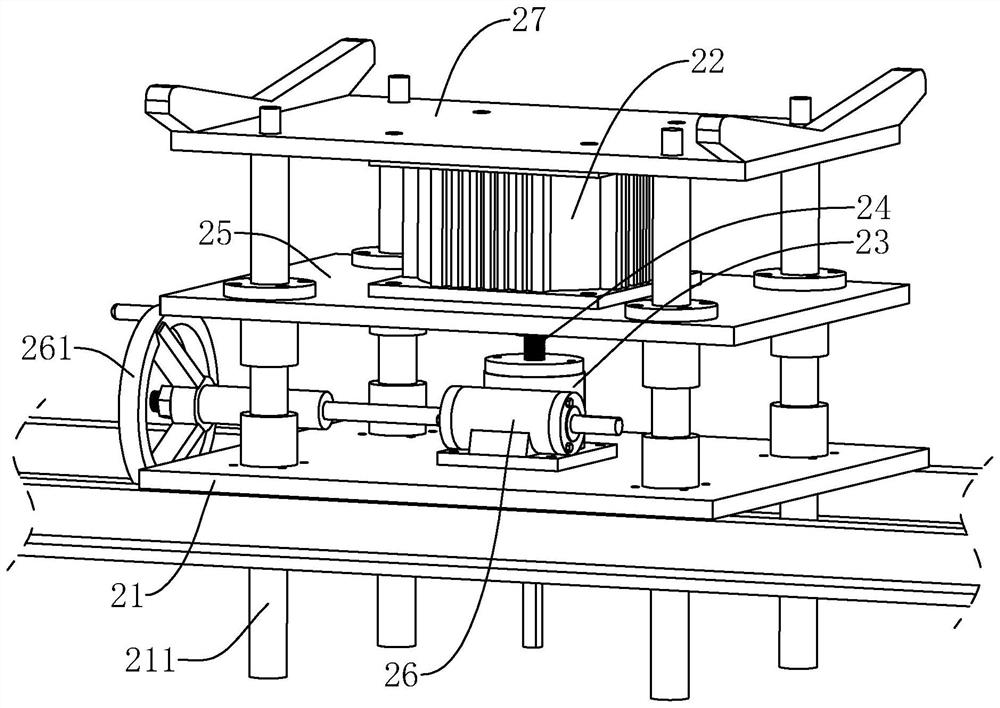

[0055] refer to Figure 4 and Figure 5 , the sliding plate 21 is slidably connected with the sliding seat 6 located on both sides of the threaded rod 24, the sliding seat 6 is located between the guide rods 211 in the length direction of the base 1 and slides, and the sliding seat 6 slides along the sliding direction perpendicular to the sliding plate 21, Both ends of the worm 26 pass through and are rotatably connected to the sliding seat 6 to drive the worm 26 to slide toward or away from the turbine 23 .

[0056] refer to Figure 5 One end of the sliding seat 6 is also fixedly connected with a second motor 62 that drives the worm 26 to rotate. The bottom wall of the support plate 27 is fixedly connected with a lifting rod 63, the lifting rod 63 slides through the bottom plate 25 and the slide plate 21, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com