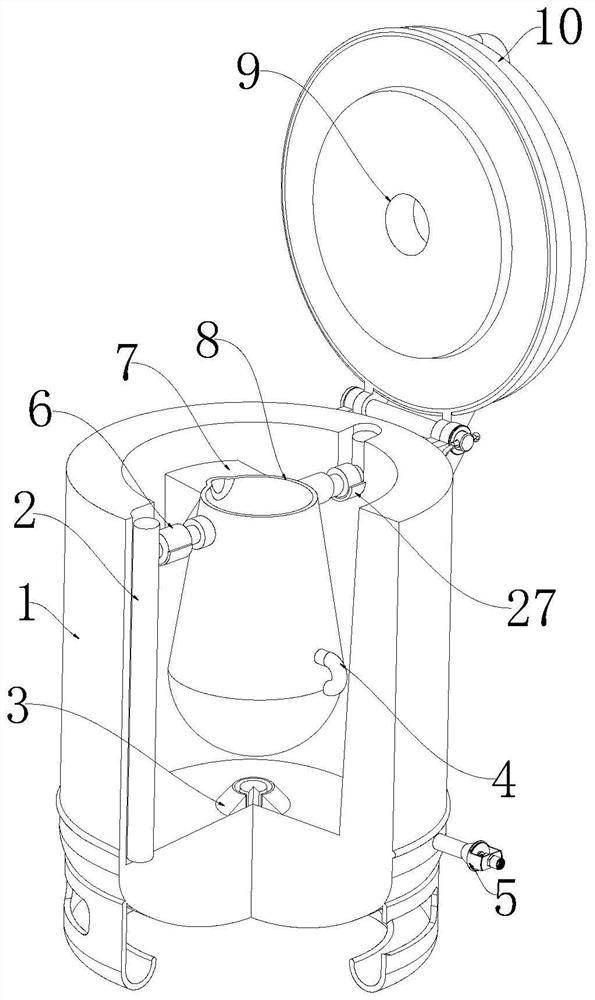

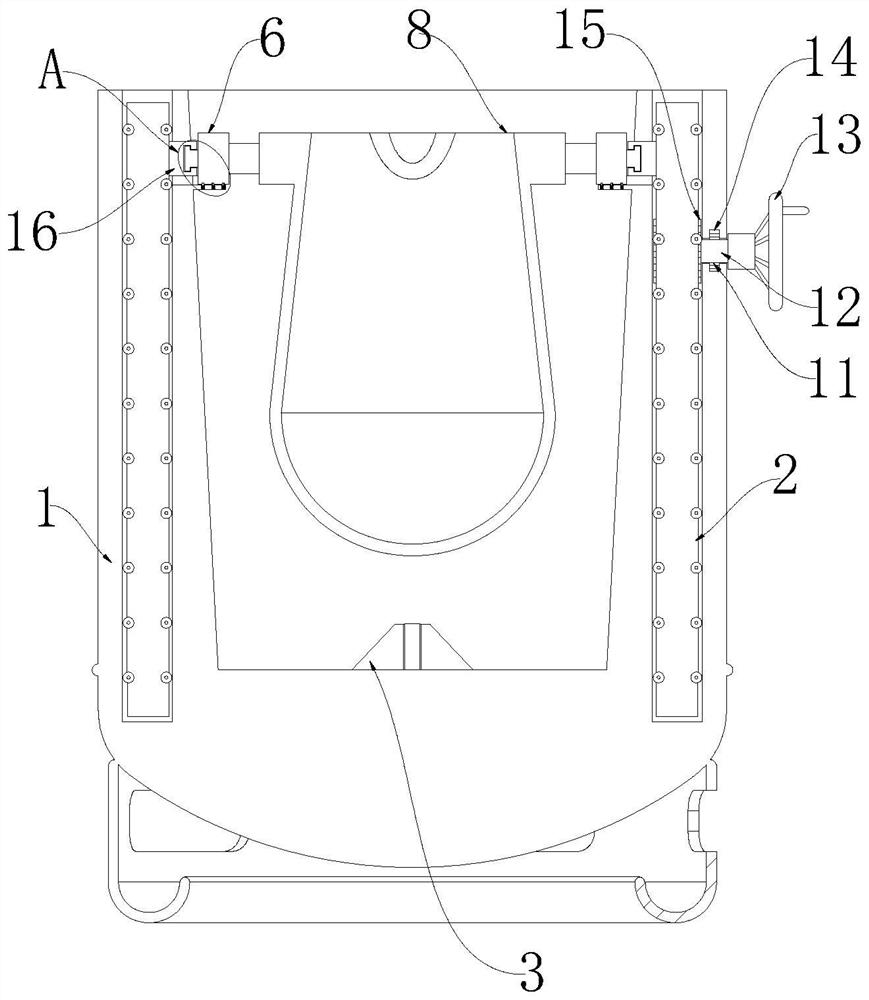

Aluminum profile smelting furnace

A technology for smelting furnaces and aluminum profiles, applied in the field of aluminum profile processing, which can solve problems such as burns and difficult operations for users, and achieve the effects of avoiding burns, simple operation, and preventing reversal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

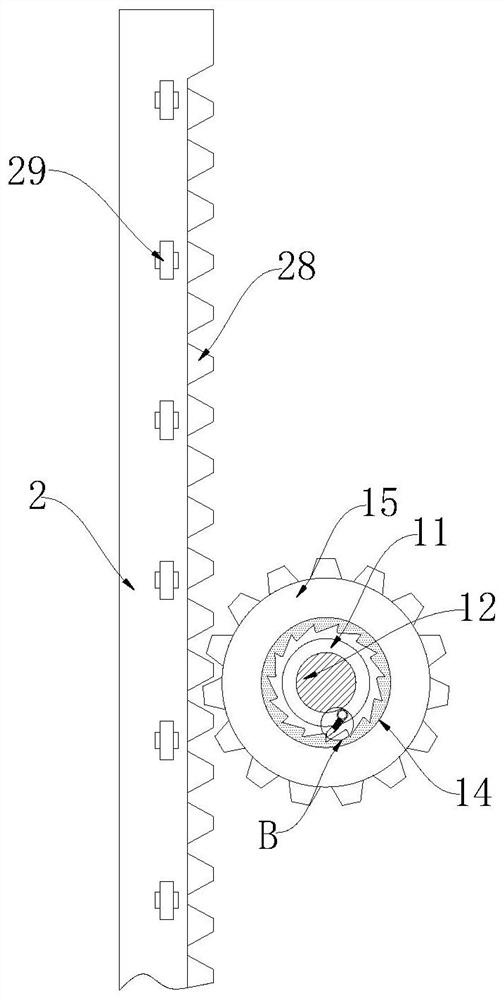

[0060] As an embodiment of the present invention, refer to Image 6 , the card position mechanism includes a rotating shaft 22 rotatably installed on the side wall of the inner wheel 11, the side wall of the rotating shaft 22 is fixedly connected with a card seat 23, a card seat 2 26 is movably installed in the card seat one 23, and the card seat two 26 is in close contact with the inner wall of the outer card wheel 14 .

[0061] The first card seat 23 and the second card seat 26 can be slightly moved on the inner runner 11 through the rotating shaft 22 . During the rotation of the inner runner 11 , the second card seat 26 can slide into another groove of the outer card wheel 14 . , the inner runner 11 can be resisted, which can prevent the inner runner 11 from rotating in the reverse direction, and further can prevent the second connecting shaft 12 from rotating in the reverse direction, which is beneficial to the stability of the melting tank 8 during the moving process.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com