Compressor oil way automatic circulating device for hydrogen refueling station

An automatic circulation and compressor technology, which is applied in the field of hydrogen refueling stations, can solve the problems of liquid leakage, easy to carry residues, cut diaphragms, etc., and achieve the effects of preventing residues from floating up, improving the closing effect, and improving the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

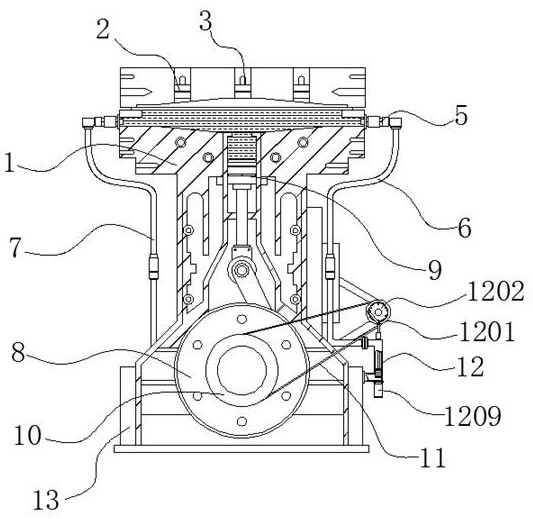

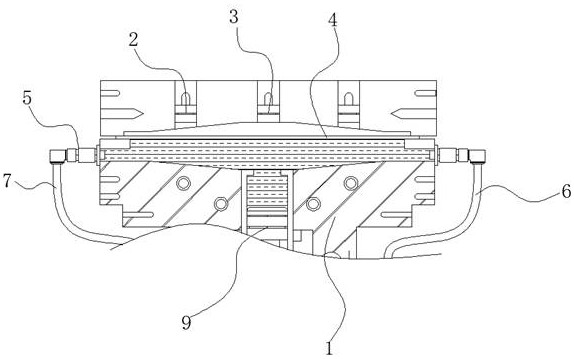

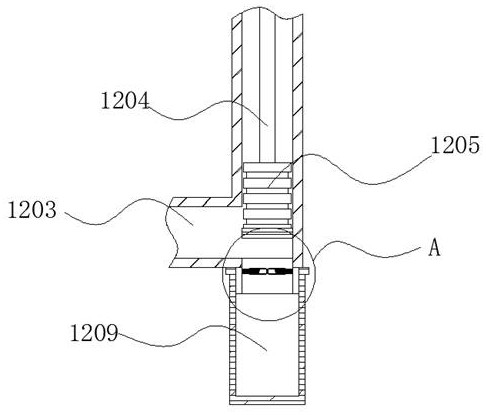

[0026] see Figure 1 to Figure 5 , the present invention provides a technical solution: an automatic circulation device for a compressor oil circuit for a hydrogen refueling station, comprising a compressor housing 1 and an oil filter assembly 12, and an intake valve 2 is provided on both sides of the top of the compressor housing 1, and An exhaust valve 3 is connected to the middle of the top surface of the compressor casing 1, a diaphragm 4 is arranged at the inner top of the compressor casing 1, and a check valve 5 is connected to both sides of the compressor casing 1. The compressor casing 1 The oil inlet pipe 6 is connected to the outer end of the check valve 5 on the right side, and the oil discharge pipe 7 is connected to the outer end of the check valve 5 on the left side of the compressor casing 1. The bottom of the inner wall of the compressor casing 1 is provided with a first crankshaft 8, and the top of the first crankshaft 8 is connected with a telescopic piston 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com