Adjustable clamp for mounting nickel-based single-crystal high-temperature alloy wafer sample

A technology of nickel-based single crystal and high-temperature alloy, which is applied in the field of high-temperature deposition experiments of micron particles, can solve the problems of lack of fixtures and other problems, and achieve the effects of saving time, facilitating rotation, and reducing the number of replacements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

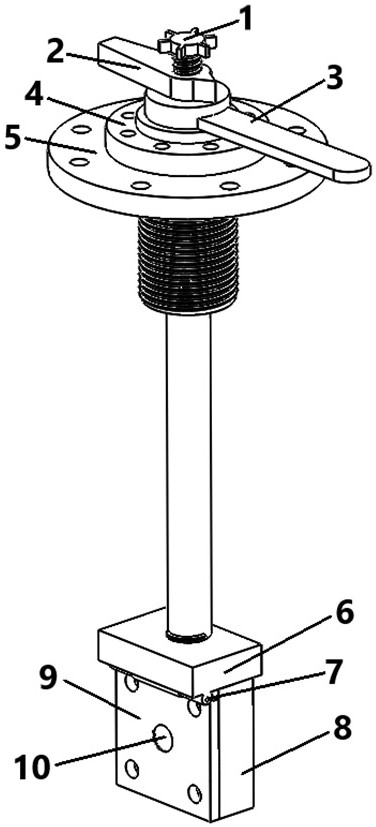

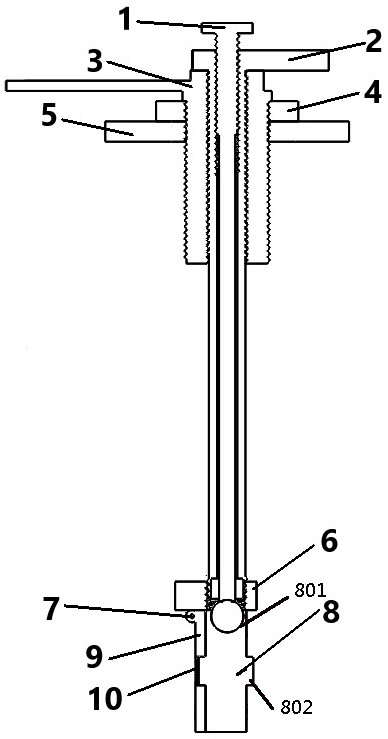

[0032] The technical solutions in the embodiments of the present invention will be clearly and completely described below according to the accompanying drawings.

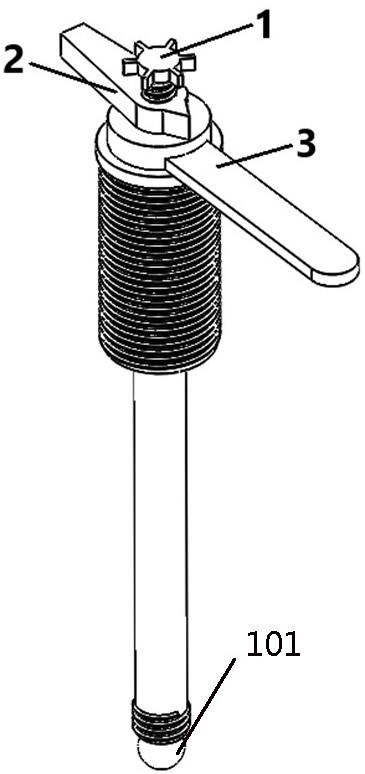

[0033] An adjustable clamp for installing nickel-based single crystal superalloy wafer samples, including a clamp control end, a flange plate, a connecting nut 6, and a clamp fixing end; the flange plate and the clamp control end are connected by threads , the flange plate is used to fix the fixture at the opening position of the experimental cabin;

[0034] The control end of the fixture includes an angle adjustment knob 1, an angle adjustment handle 2, and a height adjustment handle 3 that are screwed together coaxially from top to bottom in sequence. The plane angle is adjusted, and the vertical plane angle of the nickel-based single crystal superalloy wafer sample 10 is adjusted, and the angle is read by the number of rotations; the angle adjustment handle 2 adjusts the horizontal rotation angle of the fixed end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com