Intelligent deburring special machine for engine connecting rod

An engine connecting rod and deburring technology, which is applied in the field of engine connecting rod processing, can solve the problems of inconvenient tool replacement and low deburring efficiency of connecting rod oil holes, so as to improve the production pass rate and output rate, and the use effect is good , the effect of cleaning the inner wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

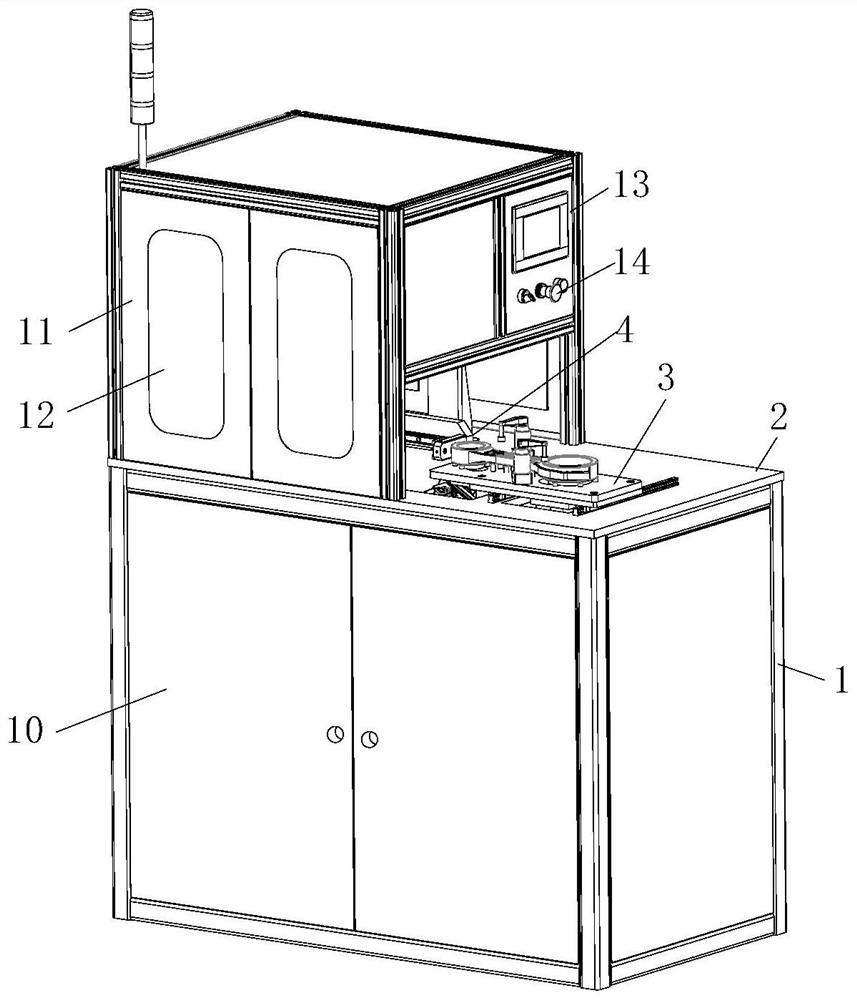

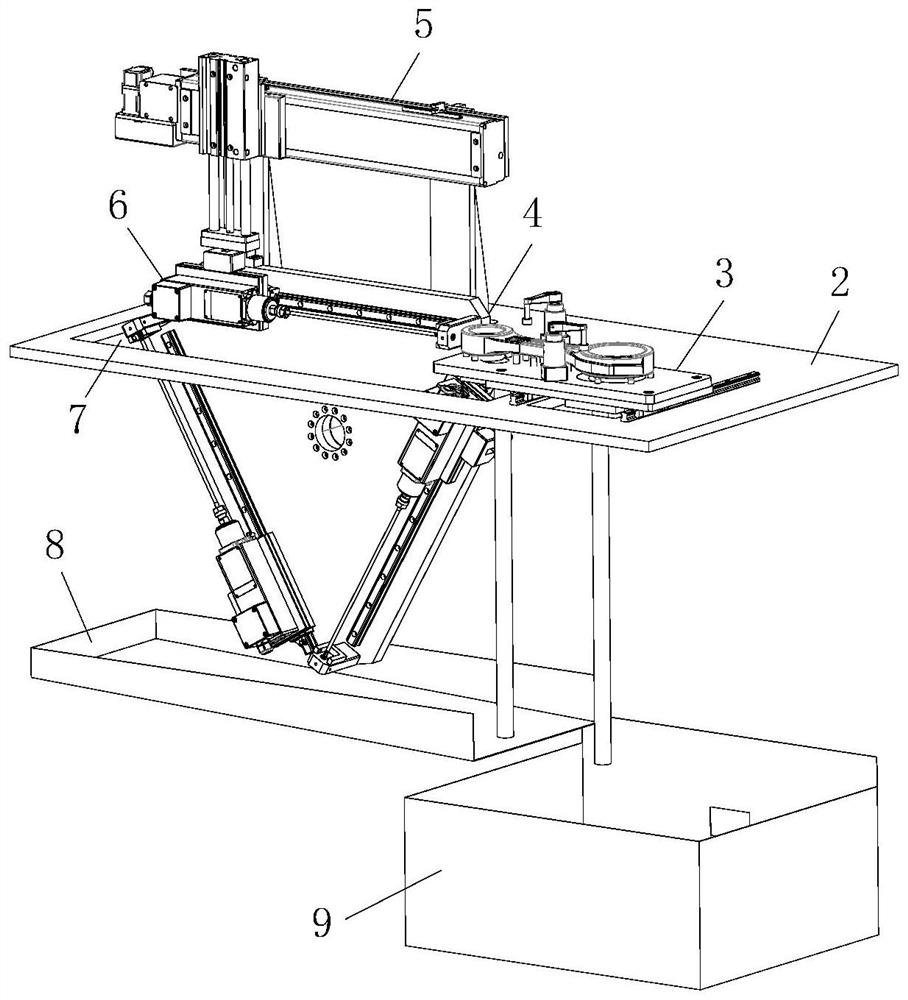

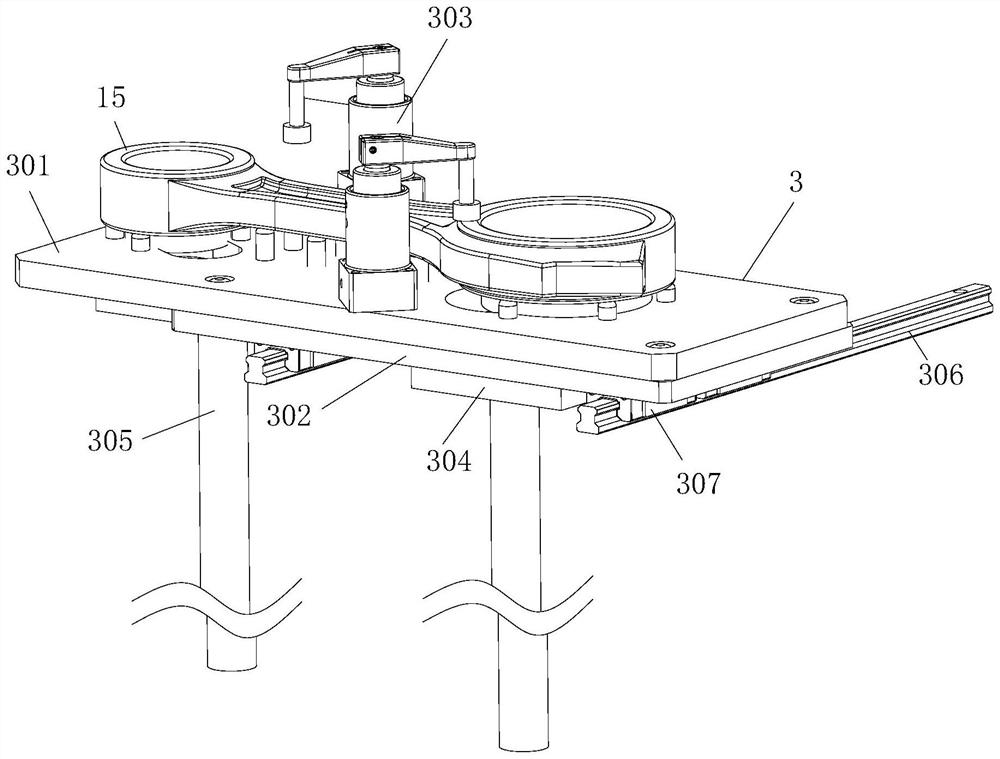

[0027] This specific embodiment is a special machine for intelligent deburring of engine connecting rods, the schematic diagram of which is as follows: figure 1 The schematic diagram of its local structure is shown in figure 2 As shown in the figure, the special deburring machine includes a workbench 1, a platen 2 arranged on the upper side of the workbench 1 for fixing, and a positioning tooling fixture 3 arranged on the upper side of the platen 2 for placing the engine connecting rod; the positioning tooling The upper side of the fixture 3 is provided with a connecting rod body 15 for surrogate processing, the left side of the positioning fixture 3 is provided with a servo screw linear module 5 for adjusting the lateral position, and the right side of the servo screw linear module 5 is provided with a The compressed air gun 4 for cleaning the waste oil hole of the connecting rod body 15, the lower side of the servo screw linear module 5 is provided with a reamer spindle mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com