Food emulsion gel with wide pH tolerance range and preparation method thereof

An emulsion gel and tolerance technology, which is applied in the field of food emulsion gel and its preparation, can solve problems such as pH influence, and achieve the effect of stable gel properties, firm and stable gel network structure, and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Preparation of water phase: Weigh 1.0g xanthan gum and 49.0g deionized water, heat under 60℃ water bath for 20min and stir until fully hydrated;

[0044] Preparation of oil phase: Weigh 3.0 g of sodium stearoyl lactylate and 47.0 g of rapeseed oil, stir and heat with a magnetic stirrer at a speed of 200 rpm at 60° C. for 10 min until sodium stearoyl lactylate is completely dissolved in the oil phase;

[0045] Preparation of emulsion gel: Mix and stir the water phase and the oil phase in a constant temperature water bath at 60°C for 20 minutes, shear with a high-speed disperser at a speed of 10,000 rpm for 3 minutes, and place it at room temperature for 12 hours after shearing to obtain a 3S1X food emulsion. glue;

Embodiment 2

[0047] Preparation of water phase: Weigh 2.0g xanthan gum and 48.0g deionized water, heat under 60℃ water bath for 20min and stir until fully hydrated;

[0048] Preparation of oil phase: Weigh 2.0g sodium stearoyl lactylate and 48.0g rapeseed oil, stir and heat with a magnetic stirrer at a speed of 200rpm at 60°C for 10min until sodium stearoyl lactylate is completely dissolved in the oil phase;

[0049] Preparation of emulsion gel: Mix and stir the water phase and the oil phase in a constant temperature water bath at 60°C for 20 minutes, shear with a high-speed disperser at a speed of 10,000 rpm for 3 minutes, and place it at room temperature for 12 hours after shearing to obtain a 2S2X food emulsion. glue.

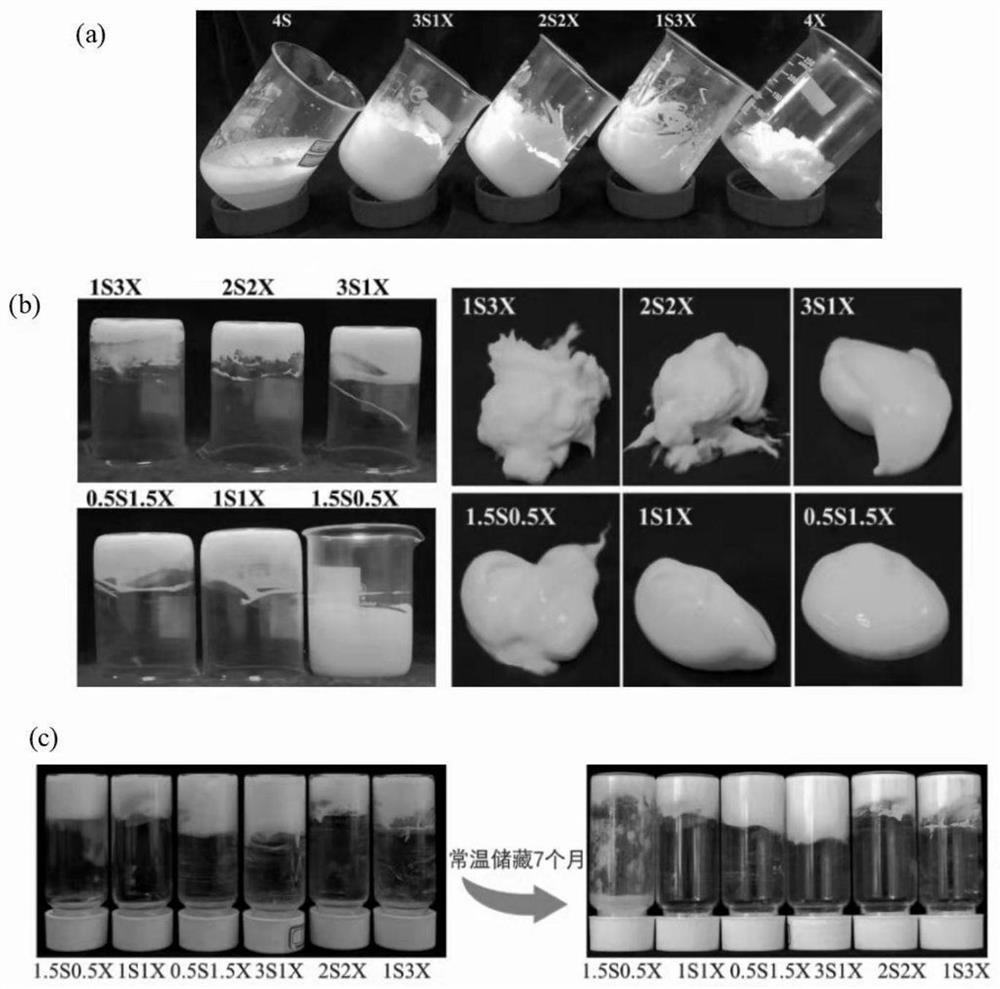

[0050] Take the prepared food emulsion gel for pH tolerance investigation: take the emulsion gel and place it in an aqueous solution of pH=3 to 9, 1 mol / L hydrochloric acid and 0.1 mol / L sodium hydroxide to observe changes, and then continue the emulsion The gel product...

Embodiment 3

[0052] Preparation of water phase: Weigh 3.0g xanthan gum and 47.0g deionized water, heat in a water bath at 60°C for 20min and stir until fully hydrated;

[0053] Preparation of oil phase: Weigh 1.0 g of sodium stearoyl lactylate and 49.0 g of rapeseed oil, stir and heat with a magnetic stirrer at a speed of 200 rpm at 60° C. for 10 min until sodium stearoyl lactylate is completely dissolved in the oil phase;

[0054] Preparation of emulsion gel: Mix and stir the water phase and the oil phase in a constant temperature water bath at 60°C for 20 minutes, shear with a high-speed disperser at a speed of 10,000 rpm for 3 minutes, and place it at room temperature for 12 hours after shearing to obtain a 1S3X food emulsion. glue.

[0055] Take the prepared food emulsion gel for pH tolerance investigation: take the emulsion gel and place it in an aqueous solution of pH=3 to 9, 1 mol / L hydrochloric acid and 0.1 mol / L sodium hydroxide to observe changes, and then continue the emulsion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com